Release 1.2., Ratified, Feb 2017

EPCIS and CBV Implementation Guideline

Using EPCIS and CBV standards to gain visibility of business processes

Contents

- 2.1 What's in the EPCIS and CBV standards?

- 2.2 Example of EPCIS Visibility Data

- 2.3 EPCIS in business applications

- 2.4 Benefits and business opportunities

- 2.5 EPCIS Data in relation to other types of...

- 2.6 How EPCIS fits into a typical IT landsca...

- 2.7 EPCIS and GS1 standards

- 3.1 The What dimension

- 3.2 The When dimension

- 3.3 The Where dimension

- 3.4 The Why dimension

- 3.5 EPCIS Event types and action

- 3.6 EPCIS and the Core Business Vocabulary (...

- 3.7 Putting it together

- 4.1 Step 1: Collect Visibility goals and req...

- 4.2 Step 2: Document the Business Process fl...

- 4.3 Step 3: Break each process flow into a s...

- 4.4 Step 4: Decide which business steps requ...

- 4.5 Step 5: Model the completion of each ste...

- 4.6 Step 6: Decide what data fields are to b...

- 4.7 Step 7: Determine the Vocabularies that ...

- 4.8 Step 8: Document the Visibility Events i...

- 5.1 Aggregation/Disaggregation

- 5.2 Drop Shipment

- 5.3 Class-Level Tracing

- 5.4 Instance/Lot Master Data (ILMD)

- 5.5 Transformation

- 5.6 Coupons and Vouchers

- 5.7 Returnable Asset Management Using GRAI

- 5.8 User/Vendor Extension Elements

- 5.9 Erroneous events

- 6.1 Sharing EPCIS Data within a single organ...

- 6.2 EPCIS Queries

- 6.3 Query Modes: Pull vs Push

- 6.4 The EPCIS Query Control Interface

- 6.5 Choreography Models: Sharing Data across...

- 6.6 Synchronisation of Master Data

- 6.7 Redaction of EPCIS Event Data

- 7.1 Validation of EPCIS events

- 7.2 Certification program

- 7.3 Requirements of program certification

- 7.4 Data validation portal

- 7.5 Certification of software

1 Introduction

Consumers and businesses rely on global supply chains to produce a diverse array of high quality, safe goods and services at affordable prices in a socially and environmentally responsible way. Meeting the demands of today’s consumer requires a much finer degree of supply chain visibility than has been typically exposed in the past. Up until now, this granular level of visibility has been seen in the transport and logistics industry, but not much elsewhere. Everyone has tracked a package they have ordered and has been able to see where the shipping process began, all of the stops it took in between, when it is anticipated to reach its destination and its arrival at the intended recipient. Increasingly, organisations, governments and indeed consumers want that same ability for products they purchase, the things they eat and perhaps even electronic records about things they care about.

Visibility data can describe the origin of an object (virtual or physical), each location where it is subject to a business process throughout the supply chain or other process, when those processes took place and what was occurring to that object at each point. Visibility data is the WHAT, WHERE, WHEN and WHY about an object. Capturing and sharing visibility data, either internally or across trading partners provides a view into the history of the manufacture, shipping, receiving and selling processes that allow for a more efficient, affordable and safe supply chain.

Electronic Product Code Information Services (EPCIS) is a GS1 standard that defines a common data model for visibility data and interfaces for capturing and sharing visibility data within an enterprise and across an open supply chain. The goal of EPCIS is to enable disparate applications to create and share visibility event data, both within and across enterprises. Ultimately, this sharing is aimed at enabling users to gain a shared view of physical or digital objects within a relevant business context.

1.1 Intended audience

1.2 Document scope

This guide is intended to provide supply chain stakeholders, including manufacturers, distributors, retailers, logistics providers, solution providers, business process architects, IT departments (developers) and solution providers with an introduction to implementing a visibility system using EPCIS, the Core Business Vocabulary specifically and GS1 standards.

This guide was developed to provide both overview and guidance on getting started with visibility systems using EPCIS. It is not intended to be a detailed, technical industry-specific “how to” guide. Industries including Pharmaceutical, Electronics, Logistics and Food & Agriculture, have developed industry specific implementation guides for EPCIS. This document intends to provide guidance at a basic use or foundational level, allowing those guidelines to layer on their specific industry requirements on top.

2 Overview of EPCIS

The goal of EPCIS is to enable disparate applications to create and share visibility event data, both within and across enterprises. Ultimately, this sharing is aimed at enabling users to gain a shared view of physical or digital objects within a relevant business context.

“Objects” in the context of EPCIS typically refers to physical objects that are identified either at a class or instance level and which are handled in physical handling steps of an overall business process involving one or more organisations. Examples of such physical objects include trade items (products), logistic units, returnable assets, fixed assets, physical documents, etc. “Objects” may also refer to digital objects, also identified at either a class or instance level, which participate in comparable business process steps. Examples of such digital objects include digital trade items (music downloads, electronic books, etc.), digital documents (electronic coupons, etc.), and so forth. Throughout this document the word “object” is used to denote a physical or digital object, identified at a class or instance level, that is the subject of a business process step. EPCIS data consist of “visibility events,” each of which is the record of the completion of a specific business process step acting upon one or more objects.

The EPCIS standard was originally conceived as part of a broader effort to enhance collaboration between trading partners by sharing of detailed information about physical or digital objects. The name EPCIS reflects the origins of this effort in the development of the Electronic Product Code (EPC). It should be noted, however, that EPCIS does not require the use of Electronic Product Codes, nor of Radio-Frequency Identification (RFID) data carriers, and as of EPCIS 1.1 does not even require instance-level identification (for which the Electronic Product Code was originally designed). The EPCIS standard applies to all situations in which visibility event data is to be captured and shared, and the presence of “EPC” within the name is of historical significance only.

2.1 What's in the EPCIS and CBV standards?

2.2 Example of EPCIS Visibility Data

2.3 EPCIS in business applications

2.4 Benefits and business opportunities

2.5 EPCIS Data in relation to other types of data

2.6 How EPCIS fits into a typical IT landscape

2.7 EPCIS and GS1 standards

The EPCIS standard defines:

■ A data model for visibility event data along with an accompanying concrete syntax for visibility data using the eXtensible Markup Language (XML); and

■ Open, standardised interfaces that allow for seamless integration of well-defined services in inter-company environments as well as within companies. There are two interfaces defined in the EPCIS standard:

□ A capture interface through which visibility event data conforming to the EPCIS data model may be delivered from capturing applications to a receiver, typically a persistent repository of EPCIS data; and

□ A query interface through which EPCIS event data may be requested by and delivered to a business application or a trading partner.

Standard interfaces are defined in the EPCIS standard to enable visibility event data to be captured and queried using a defined set of service operations and associated data standards, all combined with appropriate security mechanisms that satisfy the needs of user companies. In many or most cases, this will involve the use of one or more persistent databases of visibility event data, though a direct linkage between capture and query interface could be used for direct application-to-application sharing without persistent databases.

EPCIS is intended to be used in conjunction with the GS1 Core Business Vocabulary (CBV) standard [CBV1.2]. The CBV standard provides definitions of data values that may be used to populate the data structures defined in the EPCIS standard. The use of the standardised vocabulary provided by the CBV standard is critical to interoperability and critical to provide for querying of data by reducing the variation in how different businesses express common intent. Therefore, capturing applications should use the CBV standard to the greatest extent possible in constructing EPCIS data.

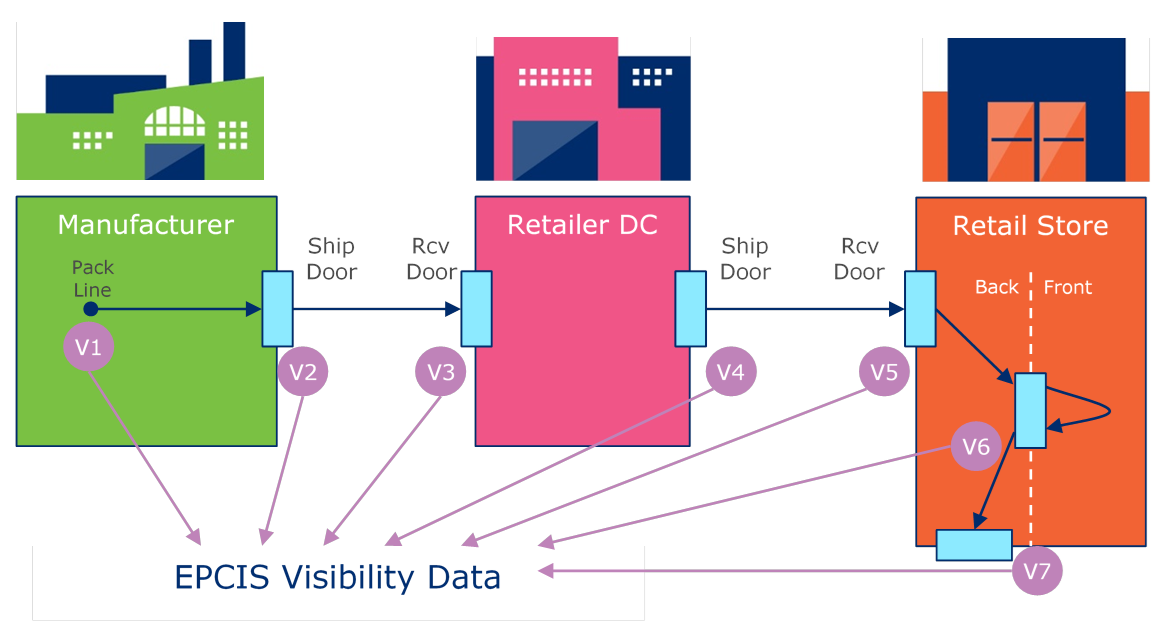

EPCIS data is intended to provide information systems with visibility as to where things are (and have been) within the business processes in which those things are handled. The following figure illustrates a simple business process, showing where EPCIS data may be generated.

Figure 2‑1 Simple Business Process Showing Generation of EPCIS Data

This figure illustrates a simple business process in which a trade item is manufactured and shipped to a distribution centre, where it is subsequently received and later shipped to a retail store, where it is received and later moved into the sales area. The entire business process may be viewed as a sequence of individual business steps: product packaging, packing into a shipping container, shipping, receiving, and so on. EPCIS data can provide a detailed record of any or all of these steps. A unit of EPCIS data that describes the completion of one business step is called an EPCIS event, and a collection of EPCIS events provides a detailed picture of a business process over time and place.

For example, a single EPCIS event records the receipt of one shipment at the distribution centre. The information content of this event is organised into four dimensions:

■ What Information about what trade items and/or shipping containers were received

■ When The date and time when receiving occurred, and the local time zone in effect

■ Where The location where the shipment was received, and where the items are expected to be following the event

■ Why Information about the business context, including:

□ The fact that the business step is a receiving operation (as opposed to shipping or some other business step).

□ The fact that the shipment is making normal forward progress through the supply chain (as opposed to being returned).

□ Information about who are the shipping and receiving parties, and the former and current owning parties if different than the shipper and receiver

□ Links to relevant business transaction documents, such as a purchase order, an invoice, a despatch advice (a.k.a. advance ship notice), etc.

Each of the business steps in the process illustrated in the figure could be the source of an EPCIS event. The details of the content of each of those events are different depending on the business step, but all have the same four-dimensional structure.

The power of EPCIS lies in bringing together individual events that are recorded over time and across a complete business process and/or supply chain. Examples of such paradigms include:

■ Finding the most recent EPCIS event for a given object, to learn where it currently is and what state it is in (“tracking”)

■ Assembling a history of events for a given object, to understand its path through an overall business process or supply chain (“tracing”)

■ Analysing a collection of events gathered over time at a particular location or within a particular business process (“analysis”)

■ Comparing the actual status of objects based on a current EPCIS event to what was expected to have happened based on a prior business transaction or a prior EPCIS event (“checking”)

■ Triggering other business processes in real time based on what a freshly captured EPCIS event reveals about the completion of a business step (“automation”)

Below are examples of business applications that can benefit from EPCIS data, along with the paradigm involved. It should be noted, however, that these paradigms are broad generalisations, and in reality a business application may make use of EPCIS data in a variety of ways that combine or step outside paradigms.

Table 2‑1 Example Business Applications and Their Use of EPCIS Data

| Business Application | How EPCIS Data Is Used | Primary Paradigm |

| Anti-counterfeiting, Provenance | Validate origin and pedigree of product | Tracing, Checking |

| Chain of custody/ownership | Document and reproduce product attributes and all partners that had physical possession of a product | Tracing |

| Couponing | Customer behaviour analysis and real-time coupon validation | Analysis, Checking |

| Customs clearance | Improve customs efficiency, reduce fraud with electronic seals | Tracing |

| Recall | Speed recalls due to precise traceability of products of concern | Tracking (to find recalled product), Tracing (to monitor progress of recall) |

| Sales promotion | Ensure that promotional goods reach consumers at the right place and time | Tracking |

| Traceability | Trace product movement forward and backward through specified stages of the extended supply chain. | Tracing |

| Business Process Optimisation | Shorten lead times, increase capacity utilisation, improve delivery quality and accuracy | Automation, Analysis |

| Exception Management | Alert process owners of deviation from desired product, timing, quantity, quality, location, status | Checking, Automation |

| Food Freshness | Monitoring whether expiration dates are not exceeded | Tracking, Automation |

| Asset Management | Keeping track of fixed assets and ensuring that adequate quantities are available to the business processes that need them | Tracking, Analysis |

| Inventory Management | Capture inventory inputs, outputs, stock taking | Tracking, Analysis |

| Process Documentation | Automate digital document generation and workflow, link to documents, products and locations identified with GS1 keys | Automation |

Each one of these applications could be deployed in one of three modes:

■ Internal: The business process exists within the facilities and is under the control of a single organisation.

■ External, Closed Chain: The business process spans more than one organisation, but all organisations involved are known in advance.

■ External, Open Chain: The business process spans more than one organisation, and the set of organisations involved is not known in advance and changes over time. This mode is typical of large supply chains involving mutual trade.

In all three modes, a key element of solution design is to determine the proper data content of EPCIS events so that the requirements of the business applications are met. In the external modes, an additional consideration is the design of the way that EPCIS events are communicated between the multiple organisations involved (often referred to as the “choreography” in contrast to the “content”).

In the external, open chain mode, the value of EPCIS and CBV being open standards is obvious: when all parties adhere to a standard, it is possible to achieve interoperability and mutual understanding of data even without prior collaboration of the parties on solution design. However, this is just as important in a closed chain or even a strictly internal application—primarily because internal applications tend to become external and closed applications tend to be come open over time. It is therefore important to follow best practices for external, open applications even when designing a closed or purely internal application.

Enhanced visibility offers a number of various benefits at all points in the supply chain in all industries. A record of processes at the point of origin or manufacture, through various distribution points, to the final point of sale to a consumer offers the potential for benefits including:

■ Optimised receiving productivity

■ Improved inventory management

■ Increased pick rates

■ Reduced errors in mispicks and shorts

■ Improved order accuracy and reduces billing errors

■ Better product and location identification throughout track and trace processes

■ Increased operational efficiencies across various business processes

■ Improved preparedness for fast and precise recalls

■ Enhanced consumer protection

■ Better product, allergen, and nutritional information delivered to consumers

EPCIS and the accompanying Core Business Vocabulary provide a technical foundation for capturing and sharing visibility data. It helps answer the questions “where is something and where has something been?” Sharing visibility data in a standard manner offers significant advantages over proprietary solutions. EPCIS allows for sharing of data between various business applications, either internally or between trading partners. EPCIS facilitates real time processing and return of event based data, both streaming (inflow and outflow of events) and complex event processing (match filtering of events). An EPCIS based system supports the demands of the consumer’s growing appetite of more and more product information, including the path the things they are purchasing have travelled.

It is important to note that EPCIS is a set of interface standards, one for capturing the data and one for querying the data. The Core Business Vocabulary provides the business context to the data model prescribed in EPCIS. Many software applications focused on traceability or other business processes that may benefit from visibility data within and across organisation implement EPCIS as a foundation. Indeed, organisations looking to develop a visibility strategy should look for solutions based on this standard.

GS1 standards in the “Share” layer pertain to three categories of data that are shared between end users:

Table 2‑2 Categories of Data in the “Share” Layer of GS1 standards

|

Data |

Description |

GS1 Standards |

|

Master Data |

Data, shared by one trading partner to many trading partners, that provides descriptive attributes of real-world entities identified by GS1 Identification Keys, including trade items, parties, and physical locations. |

GDSN |

|

Transaction Data |

Trade transactions triggering or confirming the execution of a function within a business process as defined by an explicit business agreement (e.g., a supply contract) or an implicit one (e.g., customs processing), from the start of the business process (e.g., ordering the product) to the end of it (e.g., final settlement), also making use of GS1 Identification Keys. |

GS1 eCOM XML |

|

Visibility Data |

Details about physical or digital activity in the supply chain of products and other assets, identified by keys, detailing where these objects are in time, and why; not just within one organisation’s four walls, but across organisations. |

EPCIS |

As the table suggests, visibility data (EPCIS event data) is a new type of data, different in character from either master data or transaction data.

A chief distinguishing characteristic of EPCIS data is that it occurs in much greater volume than either master data or transaction data. Like transaction data (and unlike master data), new visibility data is generated continuously as an organisation conducts more business. But visibility data occurs in greater volume because:

■ Visibility data frequently refers to individual instances of objects, for example trade items identified by the combination of a Global Trade Item Number (GTIN) and a serial number.

■ Even when visibility data refers to objects at the class level, visibility data is generated at more steps within an overall business process. For example, a trade item flowing from manufacturer to retailer may be subject to just a single business transaction (the sale from manufacturer to retailer) but be the subject of several dozen visibility events as it progresses through the manufacturer’s and retailer’s facilities.

■ Visibility data often has historical value for traceability, and so may be retained for longer periods of time than business transaction data.

Visibility data is complementary to transaction data, as some visibility events occur in the absence of business transactions and conversely some business transactions take place without handling of objects. Where the same business process simultaneously yields visibility data and transaction data, they provide complementary data.

Figure 2‑2 Overlap Between Transaction Data and Visibility Data

Examples of all three possibilities:

■ In some cases, a visibility event coincides with a business transaction, so that there may be a piece of transaction data and a piece of visibility event data describing different aspects of the same occurrence. For example, when goods are shipped from a loading dock, there may be a despatch advice (a piece of transaction data that confirms the sender’s intent to deliver specific goods to the receiver) and an EPCIS event with business step “shipping” (a piece of visibility data that confirms the observation of goods leaving the loading dock). Even in such cases, the transaction data and visibility event data may not be in 1:1 correspondence; for example, a single despatch advice may correspond to several visibility events if different parts of the shipment are handled separately.

■ A visibility event may occur with no corresponding business transaction. For example, when a trade item moves from the “back room” storage of a retail store to the sales area where a consumer can purchase it. This is a highly relevant event for purposes of assessing availability of product to consumers but it has no associated business transaction.

■ A business transaction may take place with no corresponding visibility event. For example, when a purchaser sends an “order” message to a supplier, there is a legal interaction, but nothing occurring in the physical world where the ordered products reside (in fact, the ordered products may not even exist when the order is sent).

The following simplified diagram shows how EPCIS fits in to a typical company IT infrastructure.

For the sake of discussion, this picture lumps together as “back-end applications” all of the IT components that process master data and transaction data (as defined in the previous section). The specific legacy components in use will, of course, vary widely from company to company; typical components include Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS), Master Data Management (MDM) systems, etc.

Because visibility data is a new type of data, and as discussed in the previous section visibility data often occurs in far greater quantities, it is common that new IT components are dedicated to the processing of visibility data. These components include:

■ EPCIS Repository: A persistent store for visibility data, including all EPCIS events generated internally within the organisation and whatever EPCIS events are received from trading partners.

■ EPCIS Capture Applications: Software applications deployed at the “edge” of an enterprise—in factories, warehouses, stores, etc—that generate EPCIS events as business process steps are completed.

■ EPCIS Accessing Applications: Software applications at the enterprise level that process EPCIS events to meet enterprise objectives (e.g., the objectives described in Section 2.3 ). An EPCIS accessing application might be a simple connector to a back-end application, or a complex application that carries out some new business task using EPCIS data.

The EPCIS standard defines two interfaces:

■ The EPCIS Capture Interface, by which the EPCIS Capture Applications deliver EPCIS events to an EPCIS Repository (or possibly directly to an EPCIS Accessing Application, in case of real-time processing)

■ The EPCIS Query Interface, by which EPCIS Accessing Applications retrieve previously stored EPCIS event data.

In addition, the following interactions between IT components are typical:

■ Quite often an EPCIS Capture Application receives input from Automatic Identification and Data Capture (AIDC) devices such as bar code scanners and RFID readers (including associated RFID filtering and collection software), especially when the reading of a bar code or RFID tag is the trigger to recognise that a business process step has taken place.

■ An EPCIS Capture Application may interface to one or more back-end applications to obtain relevant business context information, such as product master data or purchase order information about a shipment being received.

■ An EPCIS Accessing Application may interface to one or more back-end applications either to obtain relevant business context information or to deliver new information derived from EPCIS event data (or both).

■ An EPCIS Accessing Application may mediate the exchange of EPCIS data with trading partners.

![]() The GS1 system of standards includes standards to identify, capture, and share information about objects in supply chains. EPCIS fits in as one of the standards in the “share” group, complementing other GS1 data sharing standards for master data and transaction data, as described in Section 2.5 . The standards in the “identify” group provide the identifiers for real-world objects, allowing those objects to be referenced by EPCIS events. The standards in the “capture” group link the physical world to the world of information, and as noted in Section 2.6 they often provide the inputs to EPCIS capture applications.

The GS1 system of standards includes standards to identify, capture, and share information about objects in supply chains. EPCIS fits in as one of the standards in the “share” group, complementing other GS1 data sharing standards for master data and transaction data, as described in Section 2.5 . The standards in the “identify” group provide the identifiers for real-world objects, allowing those objects to be referenced by EPCIS events. The standards in the “capture” group link the physical world to the world of information, and as noted in Section 2.6 they often provide the inputs to EPCIS capture applications.

3 Anatomy of an EPCIS event

The information in an EPCIS event records the essentials of what happened during a step of a business process in which physical or digital objects were handled, expressed via the four dimensions of what, where, when, and why. This section looks in detail at one EPCIS event for a specific business process step to show exactly how those four dimensions are populated. Section 4 goes on to explain how to design an EPCIS for any business process step.

![]() The business process step illustrated in this section is Step V3 from the example process flow described in Section 2.2 . In the overall process, a trade item is manufactured and shipped to the distribution centre of a retailer, which subsequently ships it to a retail store. Step V3 is the step where the trade item is received from the manufacturer at the retailer’s distribution centre. In this example, we will further assume that the trade item is a large consumer product such as a bicycle or a television set; this avoids having to consider complexities such as items packed into cases or cases stacked on a pallet. The shipment in this example consists of a single trade item identified by a GTIN plus serial number.

The business process step illustrated in this section is Step V3 from the example process flow described in Section 2.2 . In the overall process, a trade item is manufactured and shipped to the distribution centre of a retailer, which subsequently ships it to a retail store. Step V3 is the step where the trade item is received from the manufacturer at the retailer’s distribution centre. In this example, we will further assume that the trade item is a large consumer product such as a bicycle or a television set; this avoids having to consider complexities such as items packed into cases or cases stacked on a pallet. The shipment in this example consists of a single trade item identified by a GTIN plus serial number.

The EPCIS event for Step V3 includes the following data:

■ The What dimension identifies the product that is received; in this case, using the GTIN and serial number of the product.

■ The When dimension indicates when the receiving operation took place.

■ The Where dimension says where the product was received, namely the distribution centre of the retailer

■ The Why dimension provides the business context. This includes identifying the step of the business process as “receiving,” indicating that the state of the product is that it is progressing normally through the forward supply chain, linking to business transaction documents such as the governing purchase order and invoice, and identifying the parties to the transfer of ownership (i.e., the manufacturer and the retailer).

The following sections discuss the information content of these data dimensions in more detail.

3.1 The What dimension

3.2 The When dimension

3.3 The Where dimension

3.4 The Why dimension

3.5 EPCIS Event types and action

3.6 EPCIS and the Core Business Vocabulary (CBV)

3.7 Putting it together

The What dimension of an EPCIS event identifies the physical or digital objects that were involved in the event. As explained in the GS1 General Specifications and the GS1 Tag Data Standard, trade items are identified using a GTIN, a GTIN plus batch/lot number, or a GTIN plus a serial number. Pallets or logistics units are identified with an SSCC. Other GS1 object identifiers include GDTI for documents, GIAI for individual assets, GRAI for returnable assets, GSRN for services, GCN for coupons, and CPID for components or parts.

In Step V3 of the example, we have a trade item identified by a GTIN plus serial number, also known as a Serialised SGTIN (SGTIN), so the what dimension of the EPCIS event for Step V3 contains the SGTIN of the trade item being received.

The When dimension of an EPCIS event says when the event took place. There are three data elements that are part of this dimension:

■ Event Time: The date and time at which the event took place.

■ Event Time Zone Offset: The time zone in effect at the place and time of the event. This is useful when an application wants to display the event time using the local time; for example, if a package is shipped from California to Brussels, the event time zone offset can be used to display the ship date/time in US Pacific time and the receiving date/time in Central Europe time.

■ Record Time: The date and time when the EPCIS event was recorded into an EPCIS repository. Unlike all other fields in the EPCIS event, the record time is not filled in when the event is captured nor does it describe anything about the business step taking place during the event. Record Time is a bookkeeping mechanism that helps when querying an EPCIS repository; with the record time you can tell whether an event returned from a query is a new event since the time of your last query.

In Step V3 of the example, the Event Time is the date and time when the product was received, and the Event Time Zone Offset records the time zone in effect then and there.

The Where dimension of an EPCIS event captures where the event physically took place and/or where things are following the event.

EPCIS events allow for two location types, readPoint and businessLocation The readPoint is the location where the event took place. The businessLocation is the location where the object(s) is now considered to reside until a subsequent event takes place. Locations may be identified using a GS1 Global Location Number (GLN), a GLN plus an extension, an industry identifier other than GLN or using geo-coordinates.

For example, a box may be scanned as it passes through a door portal. The portal it passes through may be the point in which the event is captured. Someone may be physically standing there reading it through the door, or there may be a door portal reader capturing the event. This would be the readPoint. After the boxes passes through the portal, it now sits in a particular location. This location where the box now sits would be the businessLocation. Locations can be identified at a very fine level of granularity (a specific bin in a specific spot in a warehouse), in which case a GLN plus an extension may be necessary. If a location is described at a more general level (a building), a GLN may suffice. It is important to understand how locations will be identified for the purposes of capturing visibility data.

Note, it is vitally important that the master data about locations are synchronised between internal systems or trading partners so when EPCIS refers to location using a GLN or SGLN, one can be assured that all concerned understand the location in the same way.

In Step V3 of the example, the Read Point is the location where the product was received, which for the purposes of the example we assume to be a specific loading dock door of the Retailer’s D.C., identified by a GLN with extension. The Business Location is the location where the product resides after it is received, which for the purposes of the example we assume to be the Retailer’s D.C. with no specific place within the D.C. identified. The Business Location is in that case identified by a GLN without an extension.

The Why dimension of an EPCIS event describes the business context in which the event took place. It can include any combination of the following data elements:

■ Business Step: identifies what was taking place from a business perspective at the time of the event; that is, what step of a business process was occurring. Examples include “commissioning”, “creating_class_instance”, “inspecting”, “packing”, “picking”, “shipping”, “retail_selling.” The GS1 Core Business Vocabulary (CBV) Standard, discussed further in Section 3.6 , includes a list of standard business step values.

■ Disposition: identifies the business condition subsequent to the event of the physical or digital objects named in the What dimension. Example dispositions include “active”, “in_progress”, “in_transit”, “expired”, “recalled”, “retail_sold” and “stolen.” The GS1 CBV includes a list of standard Disposition values.

■ Business Transaction List: identifies one or more particular business transactions that are relevant to an event. A business transaction is identified by a pair of identifiers: one identifier that says what type of business transaction is referenced, and a second identifier that names the particular business transaction of that type. Examples of business transaction types are purchase order (“po”), bill of lading (“bol”), despatch advice (“desadv”). The GS1 CBV includes a list of standard business transaction type values.

■ Source List and Destination List: is used to provide additional business context when an EPCIS event is part of a business transfer of ownership, responsibility or custody. As with business transactions, a source or destination is identified by a pair of identifiers: the type of the source or destination and an identifier of the source or destination of that type. The GS1 CBV (section 7.4.2) distinguishes three standard source/destination types: “owning_party”, “possessing_party”, “location”.

In Step V3 of the example, the following values might populate the Why dimension of the EPCIS event:

■ Business Step: The business step Receiving defined in the GS1 Core Business Vocabulary.

■ Disposition: The disposition In Progress defined in the GS1 Core Business Vocabulary, indicating that the product is moving normally through the forward supply chain.

■ Business Transaction List: There might be two relevant transactions: the Retailer’s purchase order, and the Manufacturer’s invoice.

■ Source and Destination: The source owning party is the Manufacturer and the destination owning party is the Retailer.

The four dimensions that describe what is happening to an object in the physical or virtual world are captured in one of four types of an “EPCIS Event”. The following is a high level summary of EPCIS event types. For details, see section 7.4 in the EPCIS 1.1 Standard.

■ EPCISEvent: generic base class for all event types.

□ ObjectEvent: represents an event that happened to one or more physical or digital objects. For example shipping or receiving a pallet using the pallet’s SSCC. This is the simplest type of event, as well as the most commonly used.

□ AggregationEvent: represents an event that happened to one or more objects that are physically aggregated together or disaggregated from each other. For example, aggregating cases onto a pallet, or removing cases from a pallet. This is the next most common type of event after ObjectEvent, and these two event types together will cover the vast majority of events in a typical business process.

□ TransformationEvent: represents an event in which input objects are fully or partially consumed and output objects are produced, such that any of the input objects may have contributed to all of the output objects. For example, consider mixing batter and chocolate chips into cookie dough, then baking the dough into a batch of cookies. Once the ingredients are “transformed”, the resulting product is packaged and labelled with an EAN or UPC that represents “consumer package of chocolate chip cookies” and can be scanned at retail.

□ TransactionEvent: represents an event in which one or more objects become associated or disassociated with one or more identified business transactions. For example, linking the pallet and cases of chocolate chip cookies to a commercial invoice.

Each event type (except for TransformationEvent) is also further qualified by the “action”; see Section 4.5 of this guideline for details.

The Core Business Vocabulary (CBV) specifies various vocabulary elements and their values for use in conjunction with the EPCIS standard [EPCIS1.2], which defines mechanisms to exchange information both within and across organisation boundaries. The vocabulary identifiers and definitions are prescribed to ensure that all parties who exchange EPCIS data using the Core Business Vocabulary will have a common understanding of the semantic meaning of that data.

This CBV is intended to provide a basic capability that meets the above goal. In particular, this standard is designed to define vocabularies that are core to the EPCIS abstract data model and are applicable to a broad set of business scenarios common to many industries that have a desire or requirement to share data. It intends to provide a useful set of values and definitions that can be consistently understood by each party in the supply chain.

Additional end user requirements may be addressed by augmenting the vocabulary elements within with additional vocabulary elements defined for a particular industry or a set of users or a single user.

The CBV includes identifier syntax (URI structure) and specific vocabulary element values with their definitions for these Standard Vocabularies:

■ Business step identifiers

■ Disposition identifiers

■ Business transaction types

■ Source/Destination types

■ Error reason identifiers

The CBV provides identifier syntax options for these User Vocabularies:

■ Objects

■ Locations

■ Business transactions

■ Source/Destination identifiers

■ Transformation identifiers

■ Event identifiers

The CBV provides Master Data Attributes and Values for describing Physical Locations, Parties, and Trade Items, including Trade Item master data attributes at the GTIN level, lot level, and instance level.

Putting together the four dimensions of What, Where, When, and Why yields the complete information content of an EPCIS event. The following table summarises the information content of the EPCIS event for Step V3 as discussed above:

Table 3‑1 EPCIS Event Information Content for Step V3 of Example Business Process

| Dim | Data Element | Contents | Comments |

|

| Event Type | Object Event |

|

| Action | OBSERVE |

| |

| What | EPC List | A list containing one element: GTIN 10614141123459 Serial 12345 | Identifies the product that was received |

| When | Event Time | Sep 23, 2012, at 10:12am UTC | The moment in time when the product was received |

| Event Time Zone Offset | −05:00 | Local time is five hours earlier than UTC | |

| Where | Read Point | GLN 5012345678900 Extension D123 | The place where the product was received, in this case a specific loading dock door at the D.C. |

| Business Location | GLN 5012345678900 | The place where the product is expected to be following the event, in this case the entire D.C. | |

| Why | Business Step | Receiving (from CBV) | A standard identifier defined in CBV 1.1 to indicate this is a receiving business step |

| Disposition | In Progress (from CBV) | A standard identifier defined in CBV 1.1 to indicate the product is moving normally through the forward supply chain | |

| Business Transaction List | A list containing two business transaction references: Purchase Order: GLN 5012345000015 PO# ABC123 Invoice: GLN 0614141000012 Inv# XYZ987 | Each business transaction reference is qualified with a GLN to make it globally unique and to identify the system or party that generated the number. “Purchase Order” and “Invoice” are standard identifiers defined in CBV 1.1 to identify business transaction types. | |

| Source List | A list containing one source: Owning Party: GLN 0614141000012 | Receiving is a step within an overall transfer of ownership from source to destination. Here, the owning party at the source (the shipper) is identified by its GLN. “Owning Party” is a standard identifier defined in CBV 1.1 to identify a type of source | |

| Destination List | A list containing one destination: Owning Party: GLN 5012345000015 | Receiving is a step within an overall transfer of ownership from source to destination. Here, the owning party at the destination (the receiver) is identified by its GLN. “Owning Party” is a standard identifier defined in CBV 1.1 to identify a type of destination |

Section 4 describes the design process in more detail, showing how this eventually results in EPCIS data conforming to the standard.

4 Designing a Visibility system using EPCIS

Building visibility systems requires both technical understanding of the EPCIS standard and a structured methodology. The following methodology is used to analyse a visibility process from a business perspective regardless of the technology used to capture events. Once a process is fully mapped, visibility events are identified and described. The technical details at the device level are omitted in this guide since we are primarily concerned with the business application of EPCIS data.

The visibility modelling methodology has these steps:

1. Collect visibility goals and requirements

2. Document the business process flows

3. Break each process flow into a series of discrete business steps

4. Decide which business steps require visibility events

5. Model the completion of each step as a visibility event - Understand what information is needed from a business application’s perspective

6. Decide what data fields are to be included in the visibility event

a. Start with standard EPCIS data fields

b. Define extension fields if necessary

7. Determine the vocabularies that populate each data field according to section 7 and 8 of the CBV standard

8. Document the visibility events in a Visibility Data Matrix

We will illustrate these steps using a simple forward logistics example. Later sections of the document describe considerations arising in other scenarios.

4.1 Step 1: Collect Visibility goals and requirements

4.2 Step 2: Document the Business Process flow

4.3 Step 3: Break each process flow into a series of discrete business steps

4.4 Step 4: Decide which business steps require visibility events

4.5 Step 5: Model the completion of each step as a visibility event

4.6 Step 6: Decide what data fields are to be included in the visibility event

4.7 Step 7: Determine the Vocabularies that populate each Data Field

4.8 Step 8: Document the Visibility Events in a Visibility Data Matrix

As more and more requirements are placed on organisations to track and trace the movement of things through the supply chain, it is important to place an emphasis on the overall goals and objectives of deploying a visibility system. “What problem are we trying to solve”?

The goal may be to meet a governmental regulation, or for improving efficiencies in the shipping process, or to ensure a high level of customer service by knowing where something they want is and when it will be delivered to the customer.

Determining the goal and then clearly documenting the requirements to meet the goal is the first step in beginning to think about how to deploy EPCIS. For example, if an organisation is trying to meet a track and trace regulation, it needs to understand what data is required, at which points in the process, where to keep the data, and who and how the data is being sent to another party. Ponce the overall requirements are understood, the detailed process flow and specific data requirements based on EPCIS and the Core Business Vocabulary can be determined.

Let’s take a look at a simplified forward logistic business flow. We will use this business flow in the following sections to illustrate the other steps in the design process.

In this business process we have a manufacturer who is manufacturing goods at his production facility. From the manufacturer’s factory, the goods are then shipped to the retailer’s distribution centre where they are received and stored. From the retailer’s distribution centre the goods are then shipped to the retail store where they are received and sold to the consumer.

Figure 4‑1 Example Business Process Flow

The overall business process flow is as follows:

1. The goods are manufactured and a product is packaged into cases which are in turn packed onto pallets.

2. The products are shipped by truck from the manufacturer’s factory to the retailer’s distribution centre.

3. The products arrive at the retailer’s distribution centre and are received into inventory.

4. The products are shipped from the retailer’s distribution centre by truck to the retail store.

5. The products arrive at the retail store and are received into the stockroom.

6. The products are moved from the stockroom to the sales floor.

7. In the retail store the product will be sold to the consumer.

The process flow of the simplified forward logistics example is shown in the following diagrams. The blue arrows show the flow, and the white rectangles each represent a single step in the process. As time moves from left to right, the horizontal axis also shows the locations involved as the product moves from one location to another.

In this example, there is an aggregation hierarchy where items are packed into cases, cases are packed into pallets, and pallets are loaded onto trucks. In such cases, it is often helpful to use the vertical axis to show at which hierarchy level each step takes place. If a process flow only works at a single level of aggregation, the corresponding diagram might be completely horizontal, or the vertical axis could be used to highlight some other aspect of the flow. At this stage, the idea is to be as clear as possible about the individual steps of the flow.

Not every step in these flow charts will lead to an EPCIS event; that is addressed in the next section.

Figure 4‑2 Forward Logistics Process Flow, Diagram 1 of 2

Figure 4‑3 Forward Logistics Process Flow, Diagram 1 of 2

Not every business step in a business process requires a visibility event. The decision about whether a given business step needs an event is typically a trade-off between what data is valuable to have and what data is feasible to collect.

Questions about what data is valuable to have include:

■ Will having detailed visibility event information about this step of the process provide useful input to some business application?

■ Is information about this step of the process required in order for an application to understand information about another step? For example, if an event at the “shipping” step includes a pallet ID, it might also be necessary to capture an earlier event at the “packing” step so that an application knows the content of the shipped pallet.

■ Is information about this step of the process required by a trading partner or by a government regulation?

Questions about what data is feasible to collect include:

■ Do the physical or digital objects involved in this step of the process have suitable identifiers? If not, is it feasible to give them identifiers?

■ For physical objects, is it feasible to affix the identifiers using a data carrier such as an RFID tag or bar code? If not, will it be possible to capture the identifier some other way?

■ Is it feasible to modify the operational process to include data capture of the visibility event? Considerations here include the cost of the necessary infrastructure (bar code scanners, RFID readers, software, etc.) and the impact on process itself (is additional labour needed, will the process slow down, etc.).

In the example, we will assume that from a business perspective it is essential to know what is shipped and received at each location. In many cases, it is also necessary to have a record of what is “commissioned”; that is, to capture an event each time a new identifier is created. But we will also assume that it is only feasible to capture data at the case and pallet level, not at the item level. We will also assume that the trucks used to move the pallets do not carry identification, and that it would not be feasible to track which trucks are used anyway.

Putting that together, this leads to capturing visibility events at the following steps in the Manufacturer’s portion of the example:

■ V1: Print and apply case label (commissioning – needed so that later steps are understandable)

■ V2: Print the pallet label (commissioning – needed so that later steps are understandable)

■ V3: Pack cases into pallet (needed so that the content of the shipment can be inferred from reading just the pallet identifier)

■ V4: Ship the pallet

These are indicated in the diagram with red circles numbered V1, V2, etc. Other steps in the diagram not carrying circles are steps for which no visibility events are captured.

Figure 4‑4 Forward Logistics Process Flow with Visibility Capture Indicated

Now we begin to design the EPCIS data that will capture what happens in the selected steps of the business process. The first step is to decide what event type best fits the situation at hand, from the list of event types as described in Section 3.5 . The event type will determine the structure of the information in the What dimension of the event.

To choose the event type, consider what physical or digital objects are involved in the event and how they relate to each other. Most often, you will choose one of the following three event types:

■ ObjectEvent: Use this if there were one or more objects involved in your event, and all the objects participated in the event in the same way. This is by far the most common event type.

■ AggregationEvent: Use this if your event involves a physical aggregation involving a “parent” object and one or more “child” objects. An example of an aggregation is 12 items (the “children”) packed into a carton (the “parent”). Other examples of aggregation include cases on a pallet, items in a tote, cartons loaded into a truck, containers loaded onto an ocean vessel, and components installed in an assembly. In all of these examples, each child retains its identity even while aggregated to the parent, and the aggregation is reversible (that is, it may be “disaggregated”).

■ TransformationEvent: Use this if your event is a process in which one or more “input” objects are consumed and one or more “output” objects are produced. Unlike an aggregation, where the children can later be separated from a parent, in a transformation the input objects no longer exist after the event. Examples of transformations include mixing raw materials to create a finished recipe, repackaging items such that the original package no longer exists and a new GTIN labels the new package, and smoking salmon to transform raw fish into smoked fish.

The fourth event type, the TransactionEvent, can be used if your event if a process in which one or more objects are definitively associated with (or disassociated from) one or more business transactions. However, because business transactions can be included in the Why dimension of all the other event types, there is seldom a need to use the TransactionEvent type.

The ObjectEvent and AggregationEvent types have an additional qualifier, the action, which says how the event relates to the lifecycle of the object and the aggregation, respectively. Specifically:

■ For an ObjectEvent the action values are:

□ ADD if the event marks the beginning of the life of the object. No other events for the same objects should precede this one. This is most often used when the business step is “commissioning.”

□ DELETE if the event marks the end of the life of the object. No other events for the same objects should follow this one. This is most often used when the business step is an end-of-life step such as “decommissioning,” “destroying,” or a business step involving sale to a consumer (if there is no possibility to track the object post-sale).

□ OBSERVE in all other cases.

■ For an AggregationEvent the action values are:

□ ADD if children are added to the aggregation during the event; e.g., when packing items into a case.

□ DELETE if children are removed from the aggregation during the event; e.g., when unpacking items from a case.

□ OBSERVE if the parent and children are in a state of aggregation during the event but no children are added or removed.

The TransactionEvent also has an action qualifier; see the EPCIS standard for details. The TransformationEvent does not have an action qualifier.

Here is how event types would be assigned to events V1 through V4 of the example from the previous section:

Table 4‑1 Assignment of Event Types to Business Process Steps in Example Business Process

| Event | Description | Event Type | Comment |

| V1 | Print and apply case label | ObjectEvent | This is the beginning of life for the SGTIN that identifies the case |

| V2 | Print and apply pallet label | ObjectEvent | This is the beginning of life for the SSCC that identifies the pallet |

| V3 | Pack cases onto pallet | AggregationEvent | Children (the cases) are added to the aggregation |

| V4 | Ship pallet | ObjectEvent or AggregationEvent | See discussion below |

In the V4 event, there is a choice in how to record the act of shipping the pallet as an EPCIS event. One approach is to use an ObjectEvent (with action OBSERVE) and include only the SSCC of the pallet in the What dimension. This makes the data capture easier, and results in a more compact event, but it means that applications receiving the data will need to consult the V3 event too if they need to infer what cases were on the pallet that was shipped. An alternative approach is to use an AggregationEvent (with action OBSERVE) and include both the SSCC of the pallet (the parent) and the SGTINs of all the cases (the children) in the What dimension. This approach makes sense if it is feasible to know the case SGTINs at the time the pallet is shipped, and if the Manufacturer wishes to be explicit about exactly which cases are on the pallet at that time. Applications receiving V4 would not need to make any inferences using V3 to know what cases are on the pallet.

The V4 example illustrates the subtle choices that sometimes must be made in deciding how to model business processes using EPCIS. To assist in such situations, it is helpful to consult industry sector-specific guidelines that provide standard EPCIS models for business processes commonly arising in those sectors.

Once the basic event types are decided upon, the next task is to decide what data to include in the What, When, Where, and Why dimensions of each event. It is tempting to approach this from the perspective of what information is available to your capturing application, such as what data comes out of an RFID reader or bar code scanner. However, EPCIS data is much more useful if you approach it from the opposite direction, namely from the perspective of a business application consuming the data. The question to ask yourself is: “what information does a business application need to understand what happened during this event?” The business application doesn’t need to know how the data was captured; it needs to know what happened from a business perspective.

A good way to proceed is to consider each of the four data dimensions in turn.

4.6.1 Designing the What Dimension

The What dimension identifies the physical or digital objects involved in the event. The structure of the information in the What dimension depends on the event type:

■ For an ObjectEvent, the What dimension contains a list of objects. All objects participate in the event in the same way.

■ For an AggregationEvent, the What dimension names a specific object as the “parent” and contains a list of other objects as the “children.” (There are two exceptions. If the action is OBSERVE the parent may be omitted, indicating that the children were observed in a state of aggregation but the identity of the parent is unknown. If the action is DELETE the children may be omitted, indicating that all children are disaggregated from the parent.)

■ For a TransformationEvent, the What dimension includes one list of objects that are the inputs to the transformation, and a second list of (different) objects that are the outputs of the transformation. (If a TransformationEvent is connected to other TransformationEvents through the TransformationID, it may omit either the inputs or the outputs; see Section 5.5.2 .)

Besides considering which objects involved the business process step are relevant to the event, you also have to determine how those objects will be named in the event. In EPCIS there are two different ways to refer to an object:

■ Instance-level Identification: If an object has an identifier that is unique to that particular object, it is called instance-level identification. Examples of instance-level identification include a Global Trade Item Number (GTIN) with a serial number (together called a Serialised GTIN, or SGTIN), a Serial Shipping Container Code (SSCC), a Global Returnable Asset Identifier (GRAI) that includes a serial number, and so on.

■ Class-level Identification: If an object has an identifier that is identical to the identifier carried by other, similar objects, it is called class-level identification. Examples of class-level identification include a GTIN plus a batch or lot number (shared by all trade items belonging to the same batch or lot), a GTIN by itself, a GRAI without a serial number, and so on.

Instance-level identification is the most powerful in terms of how EPCIS data can be used by applications, because instance-level identification makes it possible to recognise that an object referenced in one event is the very same object as an object referenced in a prior or subsequent event. On the other hand, assigning instance-level identification to objects is usually a more complex business process than assigning class-level identification.

When class-level identification is used there may be more than one object involved in the event from the same class, so a class-level identifier is usually accompanied by information that specifies the quantity. Including instance-level identification, this results in four ways an object could be identified in the What dimension of an EPCIS event:

Table 4‑2 Class and Instance Level Object Identification

|

Instance- or Class-level |

What Dimension Contents |

Meaning |

|

Instance |

An instance-level identifier (SGTIN, SSCC, GRAI with serial, etc.) |

A specific object participated in the event |

|

Class |

A class-level identifier (GTIN, GTIN+Lot, GRAI without serial, etc.) plus an integer quantity |

A specific number of objects belonging to the specified class participated in the event. The class in this case refers to discrete objects that can be counted. |

|

A class-level identifier (GTIN, GTIN+Lot, GRAI without serial, etc.) plus a real amount and unit of measure |

A quantity equal to the specified physical measure (amount + unit of measure) of the specified class participated in the event. The class in this case refers to objects that must be measured rather than counted, such as liquid dispensed in arbitrary volumes or solids dispensed in arbitrary weights. |

|

|

A class-level identifier (GTIN, GTIN+Lot, GRAI without serial, etc.), with no quantity information |

Some unspecified quantity or amount of the specified class participated in the event. |

The last case in the table, a class-level identifier with no quantity information, should only be used rarely, when it is impossible to determine the quantity or if the quantity is to be withheld for privacy reasons.

The same EPCIS event might have some objects identified using instance-level identification and others identified using class-level identification. For example, cases identified by GTIN and lot (class-level) could be aggregated to a pallet identified by SSCC (instance-level), or there could be a transformation event where some inputs are raw materials identified by class and quantity, other inputs are identified by GTIN+serial number (instance-level), and the outputs are identified by GTIN+serial number. However, a given object should only be identified one way in an event. For example, if an object event has five SGTINs which are different serial numbers for the same GTIN, the object event should include those five SGTINs but not also include the GTIN as a class-level identifier.

4.6.2 Designing the When Dimension

The When dimension is the most straightforward of the four dimensions. It is required in every event, and always contains two pieces of information:

■ EventTime: The date and time at which the event occurred. This is always expressed in a format that includes a time zone specifier, so that it unambiguously identifies a moment in time.

■ EventTimeZoneOffset: The time zone offset (relative to UTC) that was in effect at the place where the event took place. This allows the EventTime to be displayed to users in the local time where the event happened, if desired.

The correct value to use for these two data elements is usually quite obvious and so there is little design work to be done.

For a business step that takes place over a long interval of time, there may be some question as to whether EventTime should be the moment when the step begins or ends, or some moment in between. Usually, the ending time of the business step is the most appropriate. But as with all EPCIS data design questions, it should be considered from the perspective of a business application consuming the data. If it is important to business applications to know both the starting time and the ending time of a business step, you should consider whether it would be more appropriate to model the process using two EPCIS events, one for the start of the process and one for the end.

Conversely, sometimes there are several different events from a business perspective which are carried out simultaneously or in a way that would make it difficult to assign a different EventTime for each. For example, an automated manufacturing machine might assign SGTINs to twelve products (“commissioning” business step), assign another SGTIN to a case (“commissioning” again), and pack the items into the case (“packing” business step), all at once. It may not be physically all at once, but the EPCIS Capturing Application built into the machine may not have any way to distinguish the times. In such cases it may be appropriate to assign the identical event time to all EPCIS events generated, but if there is a logical sequencing of the events it is usually much better for consuming applications if the event times are slightly altered so that the chronological order is logical. In the items-into-case example, the EPCIS event for “packing” (the aggregation event) should have an event time that is later than the commissioning events, even if it is artificially set to a time only one millisecond later. This allows consuming applications to order the events by their EventTime to arrive at a logical sequence.

4.6.3 Designing the Where Dimension

The Where dimension identifies the physical location of objects in the event. The two data elements in the Where dimension are both optional, but most EPCIS events will include them. The two data elements are:

■ ReadPoint: The ReadPoint identifies where the objects named in the What dimension were at the time of the event; that is, where the event took place.

■ BusinessLocation: The BusinessLocation identifies where the objects named in the What dimension are expected to be following the event, until another event says otherwise.

The names ReadPoint and BusinessLocation can be a little confusing. For example, the ReadPoint could be just as relevant from a business perspective, or more so, than the BusinessLocation, depending on the situation. Instead of trying to read meanings into the names “read point” and “business location”, just remember the definitions: ReadPoint is the location of the objects at the time of the event, BusinessLocation is the location afterwards.

The difference between ReadPoint and BusinessLocation can be visualised by imagining a facility having several rooms connected by doorways, like this:

Imagine that an EPCIS event is captured whenever an object moves through one of the doorways; e.g., by an RFID reader stationed at each door. Imagine an object moves from Room 1 to Room 2 by passing through Door A. In this case, the ReadPoint (the location at the time of the event) is Door A and the BusinessLocation (the location afterward) is Room 2. Note that the object might move around within Room 2 without generating any new EPCIS events, so at the time it moved into Room 2 all we know about where it is afterwards is that it is somewhere within Room 2. If instead the object had moved from Room 1 to Room 2 via Door B the BusinessLocation would still be Room 2 but the ReadPoint would be Door B. On the other hand, if the object later moves in the opposite direction through Door A the ReadPoint would again be Door A but the BusinessLocation would be Room 1.

The reason it is useful to have BusinessLocation is that it helps to answer the question “where is the object right now?” If you happen to ask that question right at the moment an event takes place then the ReadPoint tells you that, but at any other time the BusinessLocation of the most recent event is the best available approximation to location of the object right now. At the same time, ReadPoint is useful because it tells you something about the past: “where was the object when X happened to it?” (where X is described by the Why dimension of the appropriate event).

A key question in designing the Where dimension is to decide at what granularity you will describe location. For example, if an object enters through a loading dock door during a receiving operation, there are several ways you could describe the location of the event (the ReadPoint), listed here from most specific (finest granularity) to least specific (coarsest granularity):

■ “Receiving Dock #5 in Building 2 of the Chicago campus of XYZ company”

■ “The receiving area in Building 2 of the Chicago campus of XYZ company” (specific door not specified)

■ “Building 2 of the Chicago campus of XYZ company” (specific area within Building 2 not specified)

■ “The Chicago campus of XYZ company” (specific building not specified)

■ “XYZ company” (specific location not specified)

Deciding what level of granularity to include in an EPCIS event is a key decision. As with most EPCIS design decisions, it will be a trade-off between what business applications need to make use of the data and what it is feasible to collect when the EPCIS event is captured. For example, distinguishing between different loading dock doors in a building may require more expensive infrastructure than just knowing that an object has entered the building. At the same time, it might not be important for business applications to know what specific door was used. Sometimes, the question of granularity is answered differently in designing EPCIS events as they are captured internally versus how they are shared with trading partners. For example, the ReadPoint might be captured internally at the level of individual loading dock doors, but then redacted to the “building” level when sharing the same event with a trading partner. (See also Section 6.7 .)

It is common for the BusinessLocation to be expressed at a coarser level of granularity than the ReadPoint, simply because an EPCIS capturing application has less certainty about where an object might be following an event compared to where it is at the moment the event takes place. It is also common for ReadPoint to be at the same level of granularity as BusinessLocation when there is no business need to express ReadPoint with any finer precision.

A special case for BusinessLocation occurs when objects are transferred from one location to another, as in shipping followed by receiving. When the object is shipped, the location of the objects following the event is obviously not the location of the shipper. But it is also not the location of the receiver, because it is only after the event captured during receiving that the object is located at the receiver. Therefore, the correct BusinessLocation for the EPCIS event captured at shipping is “unknown” – at the time of shipping, it is unknown where the object will be until the receiving operation takes place. This is expressed in EPCIS by omitting the BusinessLocation data element entirely from the shipping event.

4.6.4 Designing the Why Dimension

The Why dimension explains the business context for the event, and is crucial for business applications to make sense of EPCIS data. All of the data elements in the Why dimension are optional, but almost all EPCIS events will include at least the BusinessStep and BusinessLocation data elements. The other data elements in the Why dimension are included only when they are relevant to the business step being carried out.

The definitions of the data elements in the Why dimension were given in Section 3.4 . Here are design considerations for choosing whether to include each data element, and how to choose the appropriate values.

4.6.4.1 Designing the Business Step

The BusinessStep data element is the most important when it comes to a business application understanding what EPCIS data means. The BusinessStep value is an identifier that says what step of the business process was taking place at the time of the event. Without the business step an application only knows that an object existed at a particular place ant time; with the business step an application knows how that object relates to the overall business. Practically all EPCIS events should have a BusinessStep value. The BusinessStep value usually corresponds to a verb of some kind: shipping, receiving, packing, etc.

In order for business step values to be useful, they must have a meaning that is known in advance to the applications that will see them. For this reason, the value for BusinessStep is always defined by a standard of some kind – a document that maps a given BusinessStep value to an explanation of what the value means and how to interpret the EPCIS event carrying that value. The EPC Core Business Vocabulary (CBV) is one such standard. It is a global standard that defines several dozen business step values that apply to a variety of business steps commonly occurring in supply chain business processes across many industry sectors. Because it is a global, cross-sector standard, using CBV business step values makes an EPCIS event intelligible to the widest set of applications. When a CBV business step value is applicable, it should be used.

Sometimes, however, you may be using EPCIS in a business process that includes a step that does not fit very well with any of the business step values defined in the CBV. In such cases, a different identifier must be used, one that you create yourself for the specific application. There will still be a document that defines the identifier and its meaning – in this case the document is an internal design document rather than a global standard. Specific business step values may also be defined across a group of trading partners, or by a sector-specific standard. However, all such values will result in EPCIS events that can only be understood within the smaller group of organisations that is aware of the narrower standard or design document that defines them. This is a trade-off that must be considered when deciding whether to use the CBV or not.

Section 4.7 describes how to create an identifier not defined in the CBV so as to avoid conflicts.

4.6.4.2 Designing the Disposition

The Disposition value is an identifier that indicates the business condition of the objects following the event. The Disposition value usually corresponds to an adjective that describes the business state of the objects as it relates to the overall business process: in_progress, recalled, damaged, etc.

A key use of the Disposition is to note the difference between normal flow and exceptions. For example, the Core Business Vocabulary (CBV) disposition value “in_progress” indicates objects that are moving normally through the supply chain and “recalled” indicates objects that have been recalled to the manufacturer. Having a Disposition separate from BusinessStep helps model such situations in two ways. One, at the time of an event that is subject to exceptional outcomes, the Disposition can express which outcome occurred. For example, there may be an EPCIS event with BusinessStep “inspecting” (from the CBV) where the outcome of the inspection is either Disposition “in_progress” in the usual case or “recalled” if the inspection discovers the object is subject to recall. Two, the Disposition can continue to indicate the exceptional state even as the objects are subjected to further events. For example, following the “inspecting” step a recalled object might have several EPCIS events with BusinessStep values “shipping” and “receiving” as the object works its way upstream to the manufacturer. Without Disposition these EPCIS events would be difficult to distinguish from ordinary shipping and receiving steps, but with a Disposition value of “recalled” instead of “in_progress” it becomes clear that these events are part of a reverse logistics process.

As with BusinessStep, values of Disposition are only useful if their meaning is known in advance to the applications that will see them. For this reason, all of the comments in Section 4.6.4.1 apply equally to Disposition values.

4.6.4.3 Designing the Business Transaction List

The BusinessTransactionList is a list of references to business transactions – data that are available from other systems besides EPCIS. Examples of a business transaction include: a reference to a specific purchase order, a reference to a specific invoice, and so forth. This information provides business context for an EPCIS event and helps link EPCIS data with other business information systems.

Each business transaction in the BusinessTransactionList consists of a pair of identifiers. The first is the business transaction type identifier, which says what kind of business transaction is being referenced (purchase order, invoice, etc.). The second is the business transaction identifier that references the specific transaction of the specified type.

Business transaction type identifiers are similar to BusinessStep or Disposition values in that they are useful only if their meaning is known in advance to the applications that will see them. For this reason, all of the comments in Section 4.6.4.1 apply equally to business transaction type values. The Core Business Vocabulary defines standard business transaction type identifiers for common business transaction types such as purchase order, invoice, etc.

The second part of a business transaction reference, the business transaction identifier, refers to a specific business transaction. Unlike business step, disposition, or business transaction type values there is not a fixed list of business transaction identifiers – new identifiers are constantly created as new business transactions are created. Typically, a business transaction identifier is generated by some information system other than EPCIS; for example, an invoice number might be created by an Enterprise Resource Planning (ERP) system.

A business transaction identifier must be globally unique in order to be used in an EPCIS event. This is because in processing EPCIS data an application might gather EPCIS events from across the supply chain. In that situation, it is essential that two purchase orders from different parties in the supply chain cannot be confused.