Release 2.5.1, Ratified, Jan 2018

GS1 DataMatrix Guideline

Overview and technical introduction to the use of GS1 DataMatrix

Contents

- 2.1 The encoding structures

- 2.2 GS1 element strings

- 2.3 Human readable interpretation (HRI)

- 2.4 Symbol location

- 2.5 Recommendations on encoding for defining...

- 4.1 Basic software functions

- 4.2 Symbol marking technologies

- 4.3 Selecting the right symbol marking techn...

- 4.4 General recommendations for symbol quali...

- 4.5 Colours and contrast

- 4.6 Verification of symbol (data and print q...

- 4.7 Recommendations when developing Applicat...

1 Introduction to GS1 DataMatrix

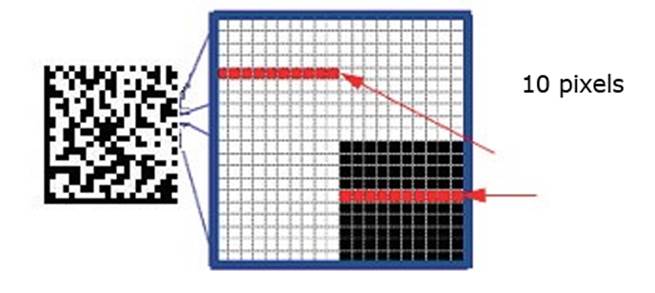

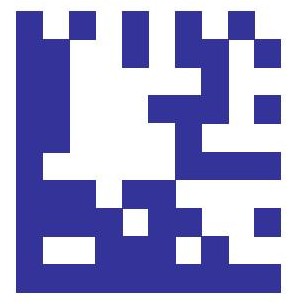

GS1 DataMatrix is a matrix (2D or two-dimensional) barcode which may be printed as a square or rectangular symbol made up of individual dots or squares. This representation is an ordered grid of dark and light dots bordered by a finder pattern. The finder pattern is partly used to specify the orientation and structure of the symbol. The data is encoded using a series of dark or light dots based upon a pre-determined size. The size of these dots is known as the X-dimension.

Before reading this document one should know the difference between data carrier and data structure. A data carrier is a graphical representation of data in a machine readable form, used to enable automatic reading of the Element Strings. GS1 DataMatrix is the ISO/IEC recognised and standardised implementation of the use of Data Matrix. The GS1 DataMatrix is formed by adding FNC1 codeword in the first position of Data Matrix ECC 200 version.

1.1 General structure

1.2 Technical characteristics

1.3 General recommendations for defining Application Standards

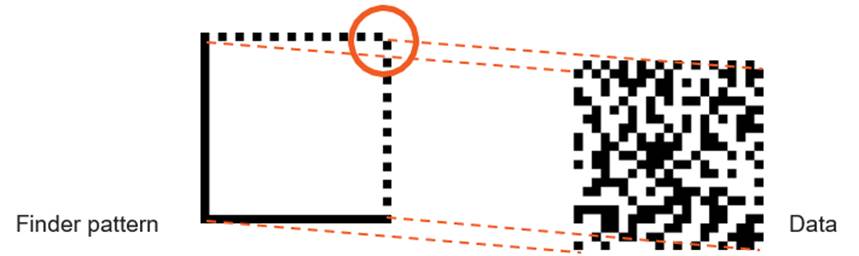

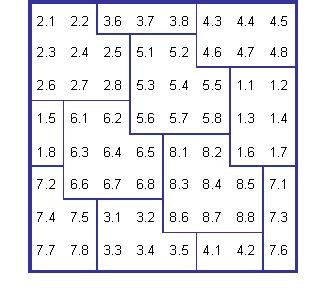

GS1 DataMatrix is composed of two separate parts (see figure below): the finder pattern, which is used by the scanner to locate the symbol, and the encoded data itself.

The finder pattern defines the shape (square or rectangle), the size, X-dimension and the number of rows and columns in the symbol. It has a function similar to the Auxiliary Patterns (Start, Stop and Centre patterns) in an EAN/UPC barcode and allows the scanner to identify the symbol as a GS1 DataMatrix.

The solid dark is called the “L finder pattern”. It is primarily used to determine the size, orientation and distortion of the symbol.

The other two sides of the finder pattern are alternating light and dark elements, known as the “Clock Track”. This defines the basic structure of the symbol and can also help determine its size and distortion.

The data is then encoded in a matrix within the Finder pattern. This is a translation into the binary GS1 DataMatrix symbology characters (numeric or alphanumeric).

Figure 1‑1 Finder Pattern and the data

Just like linear (1D) barcodes GS1 DataMatrix has a mandatory Quiet Zone. This is a light area around the symbol which must not contain any graphic element which may disrupt reading the barcode. It has a constant width equal to the X-dimension of the symbol on each of the four sides.

Each Data Matrix symbol is made up of number of rows and columns. GS1 DataMatrix always has an even number of rows and columns. Therefore it always has a light “square” in the upper right hand right corner (circled in the figure above). Obviously, this corner will be dark if the GS1 DataMatrix symbol is printed in negative (inverse reflectance printing).

1.2.1 Shape and presentation of the symbol

When implementing GS1 DataMatrix, a choice of symbol form must be made (based upon configuration support, available space on the product type, amount of data to encode, the printing process, etc.). It is possible to encode the same data in two forms of GS1 DataMatrix:

Figure 1‑2 A square form versus a rectangle form

The square form is the most commonly used and enables the encoding of the largest amount of data according to ISO / IEC 16022 Information technology – Automatic Identification and data capture techniques – Data Matrix barcode symbology specification.

However the rectangular form with its limited height is better suited to some high speed printing techniques, and to unusual printing spaces.

1.2.2 Size and encoding capabilities

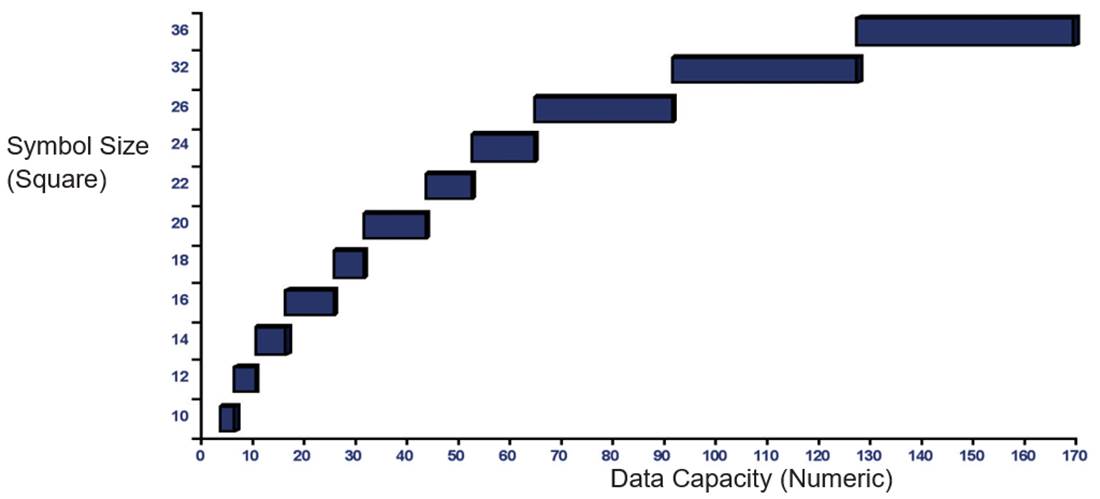

GS1 DataMatrix is capable of encoding variable length data. Therefore, the size of the resulting symbol varies according to the amount of data encoded. Accordingly, this section can approximate the size of a given GS1 DataMatrix based on this parameter.

The figure below is extracted from ISO/IEC 16022 (for the full table see Table 1‑1 ). It provides a useful guide to estimating the size of the symbol but the exact size of the GS1 DataMatrix symbol depends on the exact encoded data. See the figure below for the size and capacity graph.

Figure 1‑3 Symbol Size vs. Numeric Capacity

Table 1‑1 Table of Data Matrix symbol attributes (square form)

| Symbol size | Data region | Mapping matrix size | Total codewords | Maximum data capacity | % of codewords used for error correction no. | Max. correctable codewords error/erasure | ||||

| Row | Col | Size | No. |

| Data | Error | Num. Cap. | Alpha-num Cap. |

|

|

| 10 | 10 | 8x8 | 1 | 8x8 | 3 | 5 | 6 | 3 | 62.5 | 2/0

|

| 12 | 12 | 10x10 | 1 | 10x10 | 5 | 7 | 10 | 6 | 58.3 | 3/0 |

| 14 | 14 | 12x12 | 1 | 12x12 | 8 | 10 | 16 | 10 | 55.6 | 5/7 |

| 16 | 16 | 14x14 | 1 | 14x14 | 12 | 12 | 24 | 16 | 50 | 6/9 |

| 18 | 18 | 16x16 | 1 | 16x16 | 18 | 14 | 36 | 25 | 43.8 | 7/11 |

| 20 | 20 | 18x18 | 1 | 18x18 | 22 | 18 | 44 | 31 | 45 | 9/15 |

| 22 | 22 | 20x20 | 1 | 20x20 | 30 | 20 | 60 | 43 | 40 | 10/17 |

| 24 | 24 | 22x22 | 1 | 22x22 | 36 | 24 | 72 | 52 | 40 | 12/21 |

| 26 | 26 | 24x24 | 1 | 24x24 | 44 | 28 | 88 | 64 | 38.9 | 14/25 |

| 32 | 32 | 14x14 | 4 | 28x28 | 62 | 36 | 124 | 91 | 36.7 | 18/33 |

| 36 | 36 | 16x16 | 4 | 32x32 | 86 | 42 | 172 | 127 | 32.8 | 21/39 |

| 40 | 40 | 18x18 | 4 | 36x36 | 114 | 48 | 228 | 169 | 29.6 | 24/45 |

| 44 | 44 | 20x20 | 4 | 40x40 | 144 | 56 | 288 | 214 | 28 | 28/53 |

| 48 | 48 | 22x22 | 4 | 44x44 | 174 | 68 | 348 | 259 | 28.1 | 34/65 |

| 52 | 52 | 24x24 | 4 | 48x48 | 204 | 84 | 408 | 304 | 29.2 | 42/78 |

| 64 | 64 | 14x14 | 16 | 56x56 | 280 | 112 | 560 | 418 | 28.6 | 56/106 |

| 72 | 72 | 16x16 | 16 | 64x64 | 368 | 144 | 736 | 550 | 28.1 | 72/132 |

| 80 | 80 | 18x18 | 16 | 72x72 | 456 | 192 | 912 | 682 | 29.6 | 96/180 |

| 88 | 88 | 20x20 | 16 | 80x80 | 576 | 224 | 1152 | 862 | 28 | 112/212 |

| 96 | 96 | 22x22 | 16 | 88x88 | 696 | 272 | 1392 | 1042 | 28.1 | 136/260 |

| 104 | 104 | 24x24 | 16 | 96x96 | 816 | 336 | 1632 | 1222 | 29.2 | 168/318 |

| 120 | 120 | 18x18 | 36 | 108x108 | 1050 | 408 | 2100 | 1573 | 28 | 204/390 |

| 132 | 132 | 20x20 | 36 | 120x120 | 1304 | 496 | 2608 | 1954 | 27.6 | 248/472 |

| 144 | 144 | 22x22 | 36 | 132x132 | 1558 | 620 | 3116 | 2335 | 28.5 | 310/590 |

* Note: Symbol size does not include Quiet Zones.

1.2.2.1 Size and configuration of the symbol

The sizes provided above are given in terms of numbers of rows and columns. For the GS1 DataMatrix square-form, the number of rows and columns can vary between 10 and 144 providing 24 different potential symbol sizes.

By contrast for the GS1 DataMatrix rectangle-form, the number of rows can vary between 8 and 16 and the number of columns between 18 and 48. The GS1 DataMatrix in rectangle-form allows six sizes (the square form has 24) and its use is less widespread than the square- form.

1.2.2.2 The dimensions of the symbol

The size of a GS1 DataMatrix is dependent upon the following factors:

■ The amount and format (numeric or alphanumeric) of the encoded information: numbers and characters are encoded in terms of bits, represented by dark or light “dots” or “modules” of an identical size. The larger the number of bits required, the larger the symbol will be.

■ The size of the X-dimension (see A )

■ The choice of form: square or rectangular

1.2.2.3 Maximum amount of encoded data

The table above show the maximum amount of data that can be encoded in the square form of DataMatrix. Data Matrix can encode up to:

■ 2,335 alphanumeric characters, or

■ 3,116 numbers

As GS1 DataMatrix always requires the use of the Function 1 symbol character in its first position, its capacity is reduced to 2,334 alphanumeric characters, or 3,114 numbers

This maximum is based upon a square-form symbol made up of 144 rows and 144 columns divided into 36 Data Regions of 22 rows and 22 columns each.

For GS1 DataMatrix in the rectangle-form, the maximum capacity is:

■ 71 alphanumeric characters or

■ 96 numbers

A GS1 DataMatrix symbol can encode a sequence of numeric and alphanumeric data, structured according to the GS1 Application Identifier rules.

1.2.2.4 Data regions

The matrix symbol (square or rectangle) will be composed of several areas of data (Data Regions), which together encode the data.

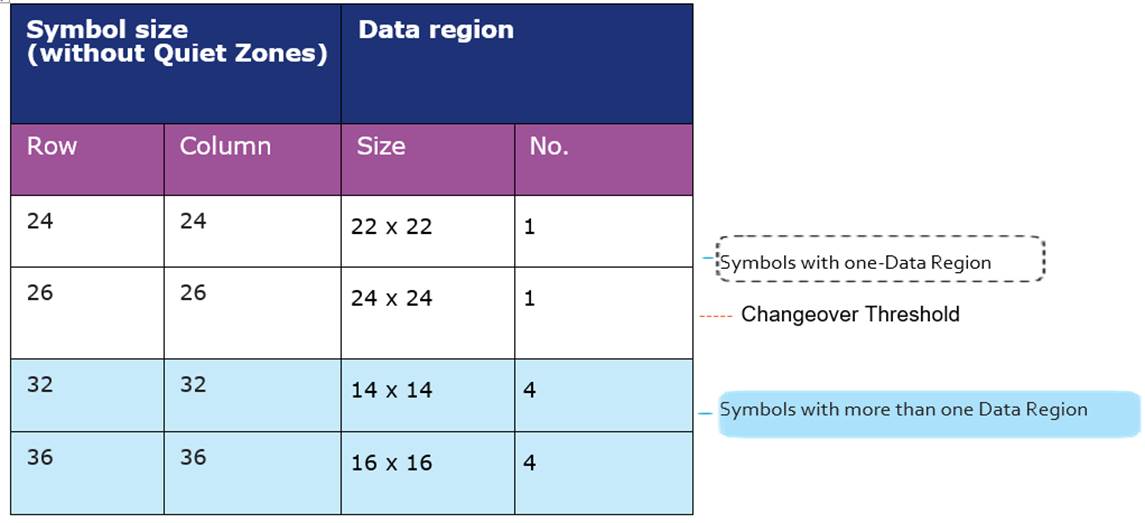

The table below shows an extract of ISO/IEC 16022, which gives details on how the Data Regions are composed. For example a symbol consists of 32 rows and 32 columns, including four sub-arrays of 14 rows and 14 columns. The number and size of “sub-matrices” within the GS1 DataMatrix symbol are shown in the column “Data Region”.

Table 1‑2 Symbol size vs. data region table

(For the full table see Table 1‑1 ).

1.2.2.5 Error correction

The table below shows the percentage of space used for Error Correction in the Data Matrix symbol and the number of codewords (data bytes) which may contain an error or be concealed without it being detrimental when scanning and reading the symbol. Example: Where 80 numeric digits have to be encoded

Table 1‑3 26X26 Data Matrix symbol attributes

| Symbol size | Data region | Mapping matrix size | Total codewords | Maximum data capacity | % of codewords used for error correction no. | Max. correctable codewords error/erasure | |||||

| Row | Col | Size | No. |

| Data | Error | Num. Row | Alpha-num. Col. | Byte Size |

|

|

| 26 | 26 | 24x24 | 1 | 24x24 | 44 | 28 | 88 | 64 | 42 | 38.9 | 14/25 |

(For the full table see Table 1‑1 ).In the extract above from the ECC 200 Symbol Attributes table of ISO/IEC 16022, we have selected the size of matrix which is equal to, or the next higher than, the amount of data to be encoded – in this case: 88 numeric digits.

Therefore, the matrix is composed of 26 rows and 26 columns.

This matrix is made up of 72 bytes, which is the sum of the total number of data and error codewords shown in the table above (44 +28)

If the encoded data, irrespective of the encodation scheme in force, does not fill the data capacity of the symbols, the pad character (Codeword value: 129) shall be added to fill the remaining data capacity of the symbol.

![]() Important:

Important:

■ The size of the Data Matrix symbol is determined by the amount of data to be encoded and not on the desired percentage of error correction.

■ However, applicable application standards define the best options for a given fixed encodation scheme

1.2.3 Error detection methods

There are several methods of error detection. An example is the check digit used by many linear barcodes, which use an algorithm to calculate the last digit of the number encoded. Check digits can confirm if the string of data is encoded correctly according to the specified algorithm. In the case of a mistake, however, it cannot indicate where the mistake was made.

Another example is to repeat data encoded within a symbol, which will help to obtain a successful read even if the symbol is damaged. This is called redundancy and can lead to some confusion when applied to GS1 DataMatrix: for GS1 DataMatrix we will talk about “Error Correction”.

Indeed, the encoding of data in a GS1 DataMatrix symbol can be done using multiple security levels. The two-dimensional structure allows the encoding of the data and mechanisms for correcting errors should they occur. These mechanisms enable the scanner to reconstitute some of the information in the event of a damaged or difficult to read GS1 DataMatrix symbol. Several security levels are described in the Data Matrix standard ISO/IEC 16022 (Information technology - International Symbology Specification). Each of the Data Matrix code types: ECC 000; ECC 050; ECC 080; ECC 100; and ECC 140 has some form of error detection and correction. ECCs that are no longer used are mentioned here for completeness.

1.2.4 Reed-Solomon error correction

GS1 DataMatrix (Data Matrix ECC 200) is the only Data Matrix configuration which employs Reed-Solomon error correction. This feature allows, to a certain extent, the location of errors and, where possible, their correction.

The Reed-Solomon error correction:

■ Calculates complementary codes and add-ins during the creation of the symbol.

■ Reconstitutes the original encoded data by recalculating the data from the complementary codes and add-ins. The recalculation regenerates the original data by locating errors at the time of scanning. Such errors may be the result of printing problems, specular reflection or degradation of the printed surface.

As outlined above (see section 1.2.2.5 ), the level of error correction depends on the relative number of error correction codewords used.

For GS1 Applications only Data Matrix ECC 200 is specified. GS1 DataMatrix is the version as defined in ISO/IEC 16022 which supports GS1 Application Identifiers (GS1 AIs) data and the Function 1 symbol character (FNC1). GS1 AIs and FNC1 are required in the GS1 DataMatrix header structure. In this way GS1 DataMatrix is different from all other Data Matrix versions and other (non-GS1) data encoding methods.

Achieving an effective business implementation of any technology depends on correctly matching the features of technology to the user needs. Please refer to the current version of GS1 General Specifications for more information on application standards.

When developing application standards for Data Matrix, users must meet to agree on:

■ The mandatory data (GS1 Application Identifiers) to be encoded. For example, if it is agreed that the business need is met by encoding between 20 and 40 digits of numeric data, then a Data Matrix symbol with 20 rows and 20 columns will meet the need.

■ The shape of the Data Matrix: square or rectangle. Indeed, both square and rectangle forms could be an option.

■ The Error Correction. For GS1 Applications only Data Matrix ECC 200 is specified and the error correction is given.

2 Encoding data

2.1 The encoding structures

2.2 GS1 element strings

2.3 Human readable interpretation (HRI)

2.4 Symbol location

2.5 Recommendations on encoding for defining Application Standards

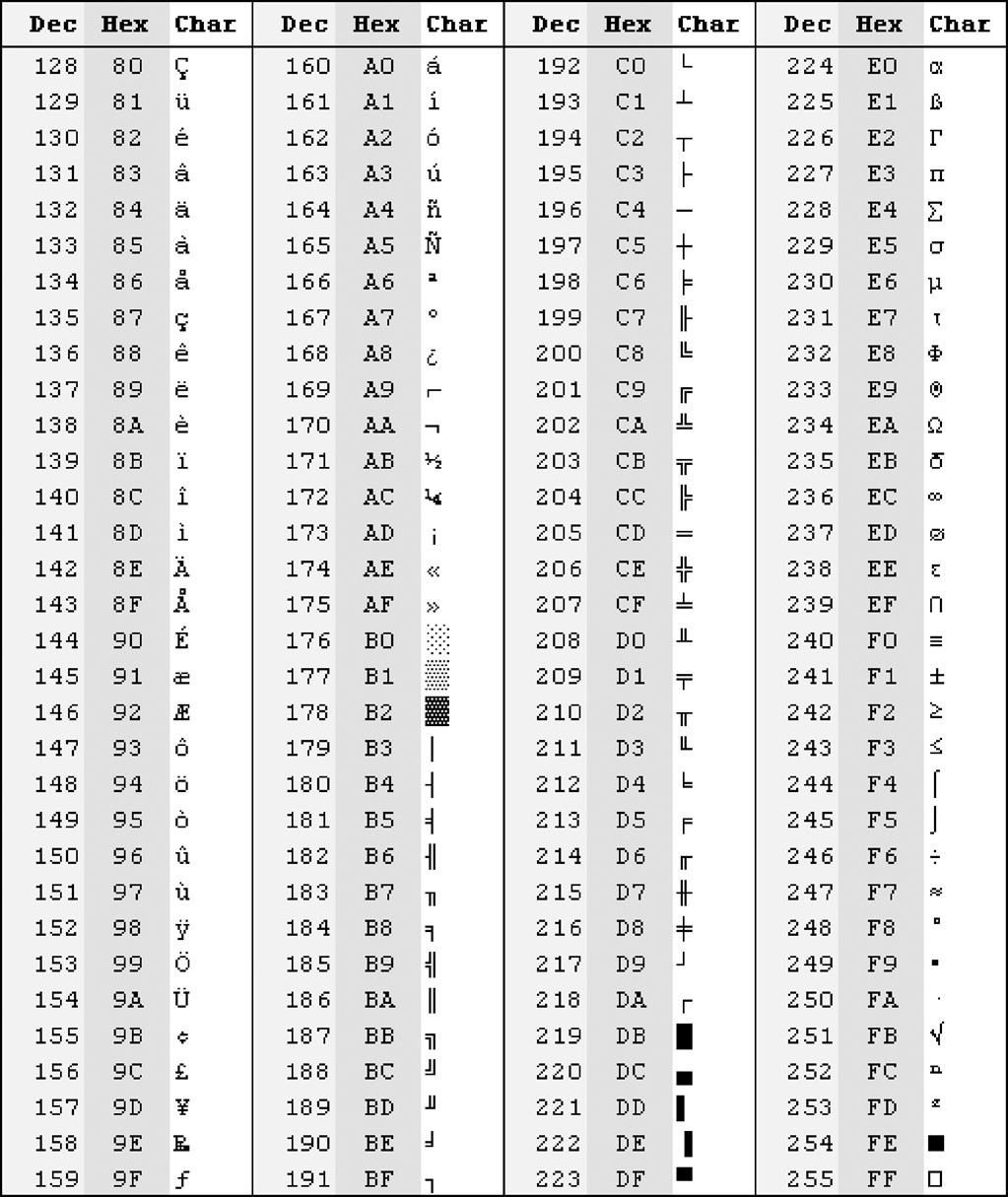

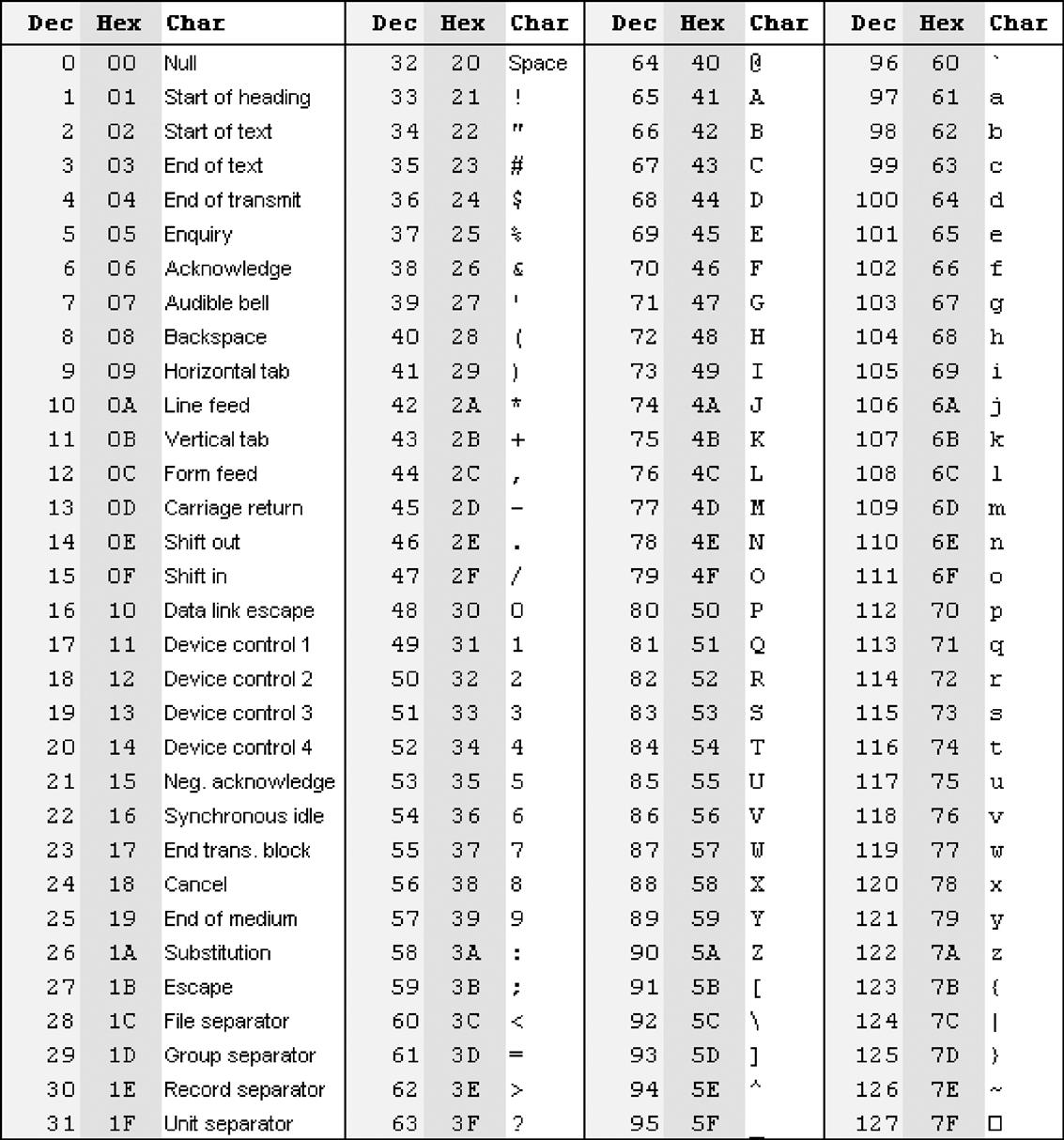

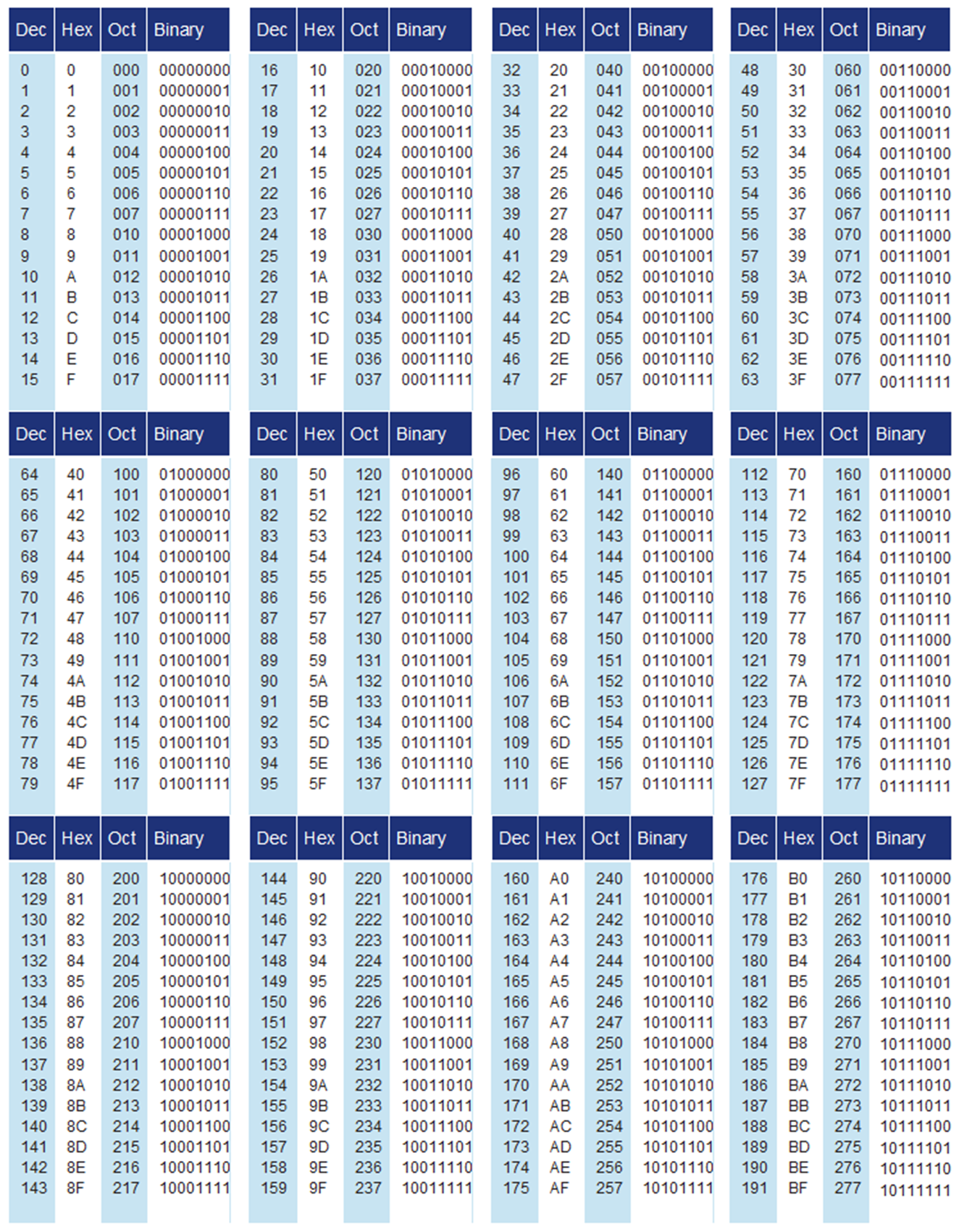

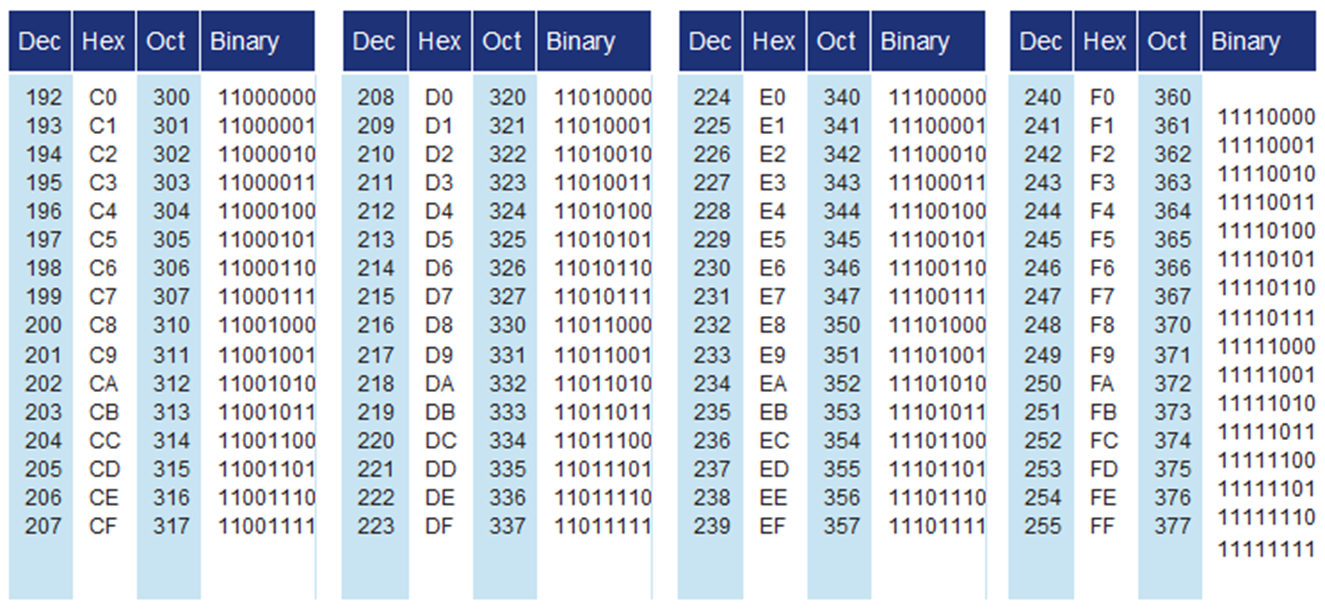

The general version of Data Matrix supports various encoding structures which can be used in the same symbol simultaneously. Examples include: ASCII, ISO/IEC 646, C40, Text, X12, EDIFACT and Base 256. These structures provide an opportunity to maximise the efficiency of encoding the required data in a Data Matrix symbol.

The simplest solution, and the one mandated by the GS1 standards, is to encode data using the subset of ISO/IEC 646 (equivalent to ASCII table 256) for all the information. This limited character set is supported by almost all computer systems available around the world today. It is strongly recommended to make ISO/IEC 646 (or the equivalent ASCII 256) the default option.

ISO/IEC 646 is derived from the ASCII (American Standard Code for Information Interchange) that was first established in the 1960s as the standard way for the binary representation of digits and the characters in the Latin alphabet. For example, the character “a” is associated with “01100001” and “A” to “01000001” in the standard ASCII 256. This enabled digital devices to communicate with each other and to process, store, and communicate character-oriented information. In particular, almost all personal computers and computer-like devices in the world started adopting ASCII encoding.

Although ASCII coding is now supplemented by additional characters, known as extended characters, to support computers encoding characters that are not used in English such as accented characters “à”, “ô” or “é”) these are not allowed for use within the GS1 System, and so not in GS1 DataMatrix. This is not because Data Matrix is unable to encode these characters, but for global use ambiguity may arise due to:

■ The same ASCII code being used for different extended characters in different geographical regions

■ The inability of many users to key enter the extended characters (due to computer limitations and human factors).

■ Only the characters contained in the ISO 646 invariant subset may be used. It should be noted that spaces cannot be encoded (see International Standard ISO/IEC 646 for representation of each character).

■ The GS1 Application Identifiers (or AIs) are used for all encoded data (see section 2.2 ).

Although it is possible to encode any type of data in Data Matrix symbols, the data must be structured according to the rules of the GS1 System when using GS1 DataMatrix.

Element strings begin with an Application Identifier which is then followed by the data that the AI denotes. The system can be characterised by:

■ A standard format for encoding data and barcoding specifications

■ A symbol architecture that allows multiple data elements (for example, item identification, expiration date, batch number, etc.) within a single barcode.

These features enable trading partner information systems to be developed in a way that enables communication via encoding and decoding the information in the GS1 DataMatrix symbol.

GS1 Application Identifiers (AIs) are 2, 3 or 4 digit numbers which define the meaning and the format of the data that follows. Each AI and its associated data can be encoded into a GS1 DataMatrix symbol in the same way – and using the same logical rules - as encoding data in the linear barcode GS1-128. Application Identifiers should be clearly recognisable to facilitate key entry. This is achieved by putting parentheses around Application Identifiers in the Human Readable Interpretation under the symbol. The parentheses are not part of the data and must not be encoded in the barcode.

This table shows six examples of common GS1 element strings:

Table 2‑1 GS1 element strings

|

AI |

Data definition |

Format (AI & data)* |

| 01 | GTIN | N2+N14 |

| 10 | Batch or lot number | N2+X..20 |

| 11 | Production date (YYMMDD) | N2+N6 |

| 15 | Best before date (YYMMDD) | N2+N6 |

| 17 | Expiration date (YYMMDD) | N2+N6 |

| 21 | Serial number | N2+X..20 |

Table 2‑2 * Meaning of the format used

|

Format |

Meaning |

| N | Numeric digit |

| X | Alphanumeric characters |

| N2 | Fixed length of two numeric digits |

| X…20 | Variable length with a maximum of 20 alphanumeric characters |

A complete list of Application Identifiers can be found in the GS1 General Specifications.

2.2.1 Function 1 Symbol Character (FNC1)

By definition in ISO/IEC 16022 GS1 DataMatrix uses a special start sequence to differentiate GS1 DataMatrix from other ISO/IEC Data Matrix symbols. This is achieved by using the Function 1 Symbol Character (FNC1) in the first position of the data encoded. It enables scanners to process the information according to the GS1 System Rules.

The FNC1 (codeword 232) has two separate uses in GS1 DataMatrix:

■ Start character.

■ Separator character to separate element strings that are not in the predefined list (see Table 2‑3 ).

![]() Important: In accordance with ISO/IEC 15424 - Data Carrier Identifiers (including Symbology Identifiers), the Symbology Identifier is the first three characters transmitted by the scanner indicating symbology type. For a GS1 DataMatrix the symbology identifier is ]d2.

Important: In accordance with ISO/IEC 15424 - Data Carrier Identifiers (including Symbology Identifiers), the Symbology Identifier is the first three characters transmitted by the scanner indicating symbology type. For a GS1 DataMatrix the symbology identifier is ]d2.

2.2.2 Concatenation

Using GS1 DataMatrix, it is possible to concatenate (chain together) discrete element strings (Application Identifiers (AIs) and their data) into a single symbol. When the element string is of predefined length, no separator character is required when another element string is added to it. When the element string is not of predefined length, it must be followed by a separator character when concatenating more element strings. The separator character may be FNC1 or the control character <GS> (ASCII value 29 (decimal), 1D (hexadecimal)). FNC1 is the character that has the codeword value 232. When either FNC1 or <GS> is used as a separator character, the scanner must transfer the character value as control character <GS>.

A separator character is never required after the last element string encoded in the symbol.

Example:

■ There are element strings with abbreviations ES 1, ES 2 and ES 3.

■ ES 1 has a predefined length (see Table 2‑3 )

■ ES 2 and ES 3 do not have predefined lengths (e.g., they contain variable length data)

■ FNC1 is used to represent the Function 1 Symbol Character.

■ <GS> is used to represent the control character <GS>.

Concatenation of three element strings, ES1, ES 2 and ES 3

| Data content of GS1 DataMatrix symbol | ||||

| FNC1 | ES 1 (predefined length) | ES 2 (non-predefined length) | FNC1 or <GS> | ES 3 (non-predefined length) |

When several element strings have to be concatenated and only one of them is of variable length, it is strongly recommended to position it at the end of the symbol. This optimises the size of the symbol by avoiding the use of a separator character.

2.2.3 Pre-defined length vs. fixed length element strings

A common mistake is to believe that any GS1 element string of a fixed length is never followed by a separator character. Only the element strings with a pre-defined length listed in Table 2‑3 do not need a separator character. All other fixed length element strings require a separator character.

Table 2‑3 shows all the element strings that were predefined in length when GS1 Application Identifiers were first introduced. This table has never been amended and there is no intention to change it in the future. It enables software decoders to be built without the risk of them having to be modified by the publication of new GS1 Application Identifiers. This table should be included in any processing software which is intended to process GS1 AIs.

The numbers in parentheses are not yet allocated. They were placed in reserve and may, in the future, be allocated to new element strings with a predefined length.

For all GS1 element strings that start with two digits that are not included in this table, it is mandatory to follow the element string with a separator character if it is not the last element string encoded in the symbol.

Table 2‑3 Element strings with pre-defined length using Application Identifiers (GS1 General Specifications Figure 5.10.1-2).

| First two-digits of the Application Identifier | Number of characters (Application Identifier and data field) |

| 00 | 20 |

| 01 | 16 |

| 02 | 16 |

| (03)* | 16 |

| (04)* | 18 |

| 11 | 8 |

| 12 | 8 |

| 13 | 8 |

| (14)* | 8 |

| 15 | 8 |

| 16 | 8 |

| 17 | 8 |

| (18)* | 8 |

| (19)* | 8 |

| 20 | 4 |

| 31 | 10 |

| 32 | 10 |

| 33 | 10 |

| 34 | 10 |

| 35 | 10 |

| 36 | 10 |

| 41 | 16 |

*Those Application Identifiers are reserved for future assignment

Example: The element string beginning with the AI (426) is defined as N3 + N3 i.e. with a fixed length data field of three digits. AI (426) does not appear in the table above and must be followed by a separator character, either FNC1 or <GS>, when other element strings are concatenated after it.

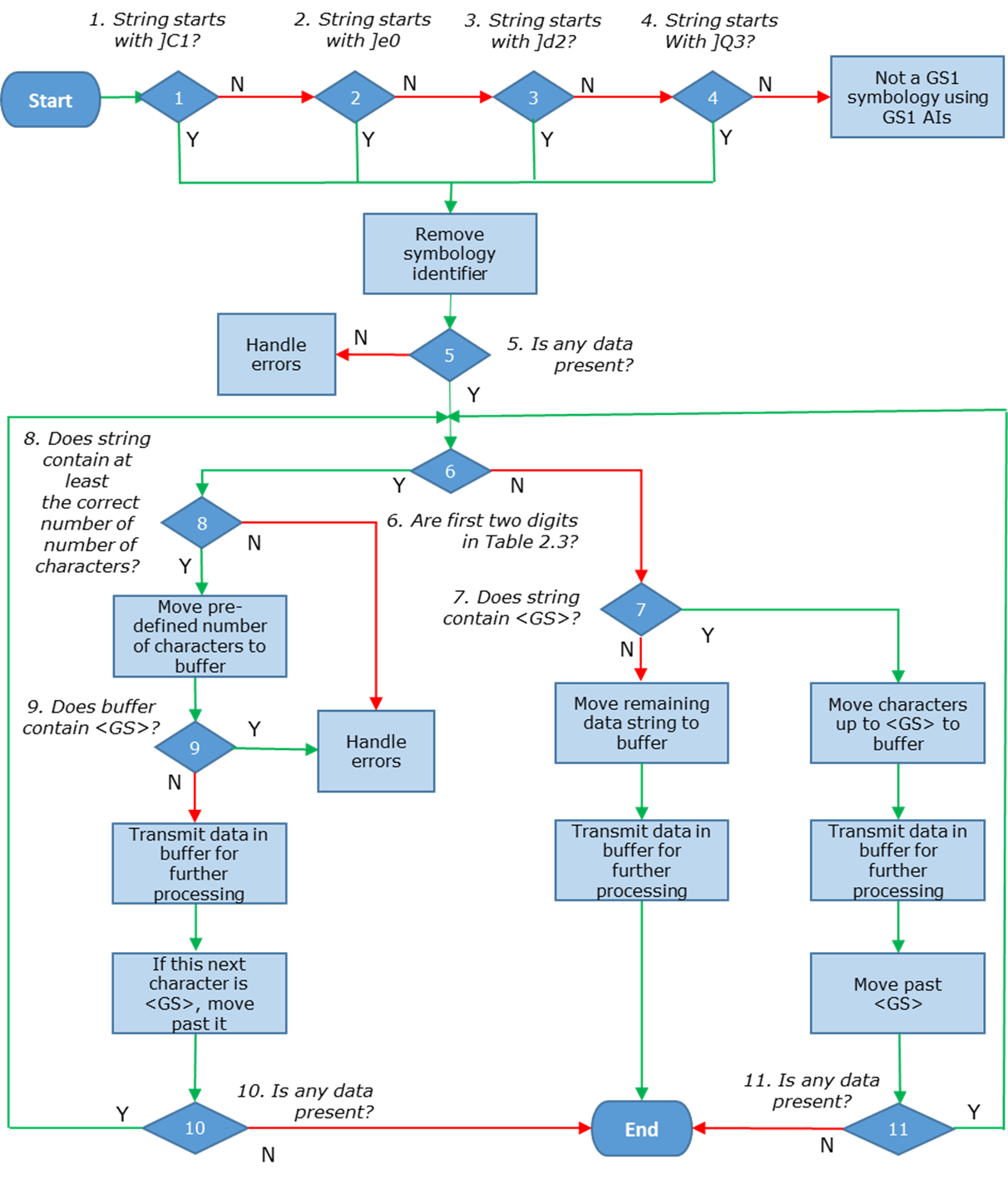

Figure 2‑1 Processing of Data from a scanned GS1 DataMatrix symbol

It is recommended to have Human Readable Interpretation of the Application Identifiers (AIs) and their associated data near the GS1 DataMatrix Symbol in which they are encoded. The precise location and font used for the Human Readable Interpretation are determined by the specific application guidelines (see section 1.3 ). Typical conventions place the primary information, such as the Global Trade Item Number (GTIN), in the human readable data underneath the barcode. The characters, however, should be clearly legible and must be obviously associated with the symbol.

Application Identifiers (AIs) should be clearly recognisable within the Human Readable Interpretation to facilitate key entry in the event that the symbol cannot be scanned. This is achieved by putting the AI between parentheses. The parentheses are not part of the data and are not encoded in the symbol. This is in clear contrast to the use of the FNC1 which must be encoded in the symbol, when used as a start or separator character, but never appears in the Human Readable Interpretation.

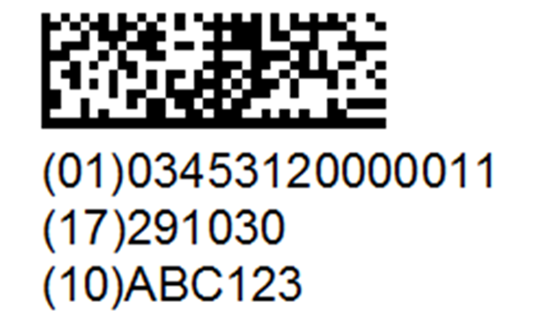

The following examples show the encoded data in the GS1 DataMatrix and how the Human Readable Interpretation could appear:

Figure 2‑2 Example 1

| Example 1 |

| Encoded String: FNC101034531200000111719112510ABCD1234

(01)03453120000011 |

Figure 2‑3 Example 2

| Example 2 |

| Encoded String: FNC101095011010209171719050810ABCD1234FNC12110

(01)09501101020917(17)190508(10)ABCD1234(21)10 |

Figure 2‑4 Example 3

| Example 3 |

|

| Encoded String: FNC101034531200000111719112510ABCD1234 The Human Readable Interpretation may also use legible text instead of the AI digits using the standardised Data Titles. In the example below, the data shown for the Application Identifier for Expiration Date requires a format that does not match the Human Readable Interpretation. As noted in the GS1 General Specifications, in this situation, only the data title of the Application Identifier can be printed, the Application Identifier is not printed: | |

|

|

GTIN (01): 03453120000011 EXPIRY: 2019-11-25 BATCH/LOT (10): ABCD1234 |

![]() Note: HRI legible text instead of AI is only allowed for Healthcare items.

Note: HRI legible text instead of AI is only allowed for Healthcare items.

Always refer to the GS1 General Specifications for complete rules and recommendations on the application and use of Human Readable Interpretation.

The exact location of a GS1 DataMatrix symbol on a product is determined by the manufacturer who will need to consider: (see Section 6 of the GS1 General Specifications for more details)

■ The available space on the product package

■ The type of product and printing substrate (packaging material)

Other packaging constraints can also greatly affect the reading of the symbol. For example folds or seams in the packaging, curvature (e.g., blister packs), etc. can all impact scanning and should be considered when selecting the most appropriate symbol location. This is especially important when printing very small GS1 DataMatrix symbols.

It should be noted, however, that thanks to its intrinsic properties, the orientation of the symbol has no impact on scanning performance.

Figure 2‑5 Rectangular form example

In terms of encoding data, the application standard must specify the following:

■ The Data Matrix syntax and encoding rules. For GS1 Applications, this syntax is already subject to technical specifications defined and recognised (ECC 200 with leading FNC1 and GS1 Application Identifiers)

■ Which Application Identifiers (AIs) to use (mandatory and optional)

■ Location and format of Human Readable Interpretation

■ If necessary, symbol placement determined by the area of application. Examples of areas of application could include: direct part marking of surgical instruments, unit- dose pharmaceuticals, logistic applications, etc.

Please refer to the current version of GS1 General Specifications for more information on application standards.

3 Reading and decoding GS1 DataMatrix

Once the symbol is printed, a reading or scanning device is required to capture the encoded data. The word ‘scanning’ is normally used to cover two separate process steps:

1. The actual scan (the reading of the dark and light areas)

2. The decode (the processing of the captured image to determine the encoded data)

In this regard GS1 DataMatrix performs very similar to the well-known linear barcodes endorsed by GS1, such as EAN-13, ITF-14, GS1-128 and GS1 DataBar. However, it differs from these linear symbols by requiring a camera or imaging based scan as data is encoded in two-dimensions.

Once decoded, the data will be passed to an information system for further processing.

3.1 Principles of reading GS1 DataMatrix

3.2 Scanners for GS1 DataMatrix

3.3 Decoding

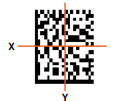

Like other 2D barcodes, GS1 DataMatrix can only be read by imaging cameras or CCD (Charge Couple Device) devices. The principle is based upon first capturing the image of the symbol and then analysing it. The finder patterns (see section 1.1 ) are used to recreate a virtual image of the matrix.

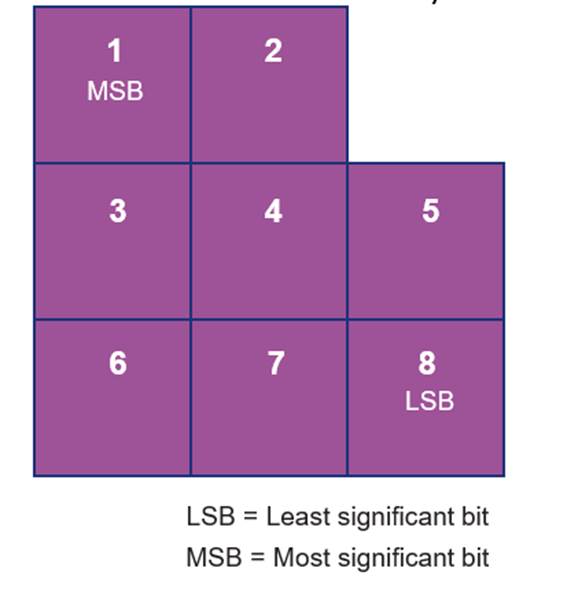

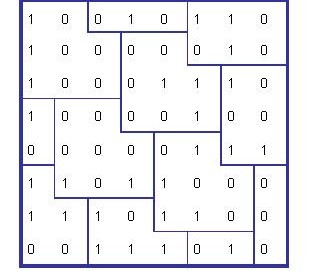

Typically, each of the dark and light areas within the matrix are converted to binary values (1 or 0). This is then processed according to the reference decode algorithm of GS1 DataMatrix as defined in ISO/IEC 16022 based upon an ideal image

Figure 3‑1 Ideal grid

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

| + | + | + | + | + | + | + | + | + | + | + |

+ = Ideal Centre of each module

3.2.1 Introduction

GS1 DataMatrix symbols require scanners that can read in 2-dimensions. Typically this requires camera or imaging technology. This is a different technology from the one used by many of the laser scanners for reading linear barcodes. A linear symbol, like EAN-13 or GS1-128 can be read by a single laser beam passing across the length of the symbol. However, to read GS1 DataMatrix symbol requires the entire image to be read in both the X and Y axis.

Camera based scanning systems tend to have the ability to distinguish up to 256 levels of grayscale. This advantage enables some specific camera based scanning systems to better handle very low contrast symbols such as those directly engraved in the metal (see section 4.5 ).

It is important to note that almost any scanner capable of reading GS1 DataMatrix can also read linear barcodes as well (GS1-128, EAN-13, UPC-A, etc.).

3.2.2 Selecting a scanner

There are a number of providers who make suitable scanning equipment. The exact choice of scanner will depend on many factors including price, operating environment, etc. There are, however, two factors which are likely to impact quality:

1. Software for image processing and decoding,

2. The optics and sensors

3.2.2.1 Image processing and decoding

The exact internal workings of a scanning and the decoding system used in a particular scanner are normally commercially sensitive information .Companies only publish the capabilities of a scanner. However, in broad terms, the decoding software must be in line with the reference decode algorithm.

The quality of the image captured will be determined, in part, by the resolution of the device and some manufacturers use ‘aggressive’ processing algorithms, using fuzzy logic, to try and read distorted images or damaged symbols. It is important to note high quality symbols are required not just to ensure good read rates with any scanner but also to protect against misreads from over-aggressive scanners.

3.2.2.2 The ability to program the scanner

Many modern scanners can be fairly simply programmed to enable or disable features. The manufacturer guide will often allow the scanner to adjust characteristics such as:

■ The symbologies that need to be read

■ The communication protocol (e.g., using symbology identifiers)

■ Reading of reverse / inverse reflectance (“black on white” or “white on black”) images Manufacturers may also provide features to deal with the non-printable characters, for example the Group Separator, which is essential for decoding messages containing variable length data.

3.2.2.3 Optics and sensors

As in the case of digital cameras, the image quality obtained depends on several factors. While important, the number of pixels is not the only factor. Indeed the sensor will have an ability to deal with a certain number of pixels and, in very broad terms, the larger the number of pixels the better the definition of the image will be. The scanner will also make use of lenses. The focal length will vary and some will be better at reading from a distance and others at reading close up. In very broad terms, reading very small barcodes is best done with scanner with a short focal distance, reading larger codes with a larger focal distance.

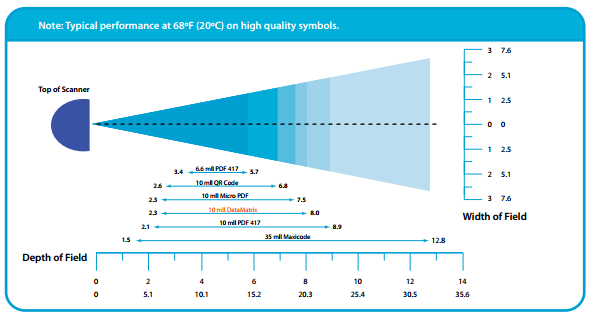

The depth of field is also an important factor. Manufacturers often show the various reading distances that the device can achieve based upon the X-dimension used.

Figure 3‑2 Typical reading distance and the depth of a scanner

The figure above is an example of typical reading capabilities of a scanner showing the reading distance and the depth of field. However, critical factors also include the type of symbol, the exact X-dimension and the print quality of the symbol.

Where the scanner is in a fixed position, it should of course be positioned at a suitable distance from the products it has to read. For hand-held scanners, the operator can easily adjust the scanning distance to obtain a scan.

As highlighted above (see section 3.1 ), scanning is in fact a two-step process. Decoding takes the scanned image and decodes the encoded data.

3.3.1 The principles of decoding

The scanner can be programmed to recognise a GS1 DataMatrix symbol, thanks to its decoding system and the unique patterns (the Data Matrix finder patterns and the leading FNC1). This is a key security feature allowing the scanner to distinguish between data encoded according to the GS1 Application Identifiers rules and any other data. This offers system protection and allows GS1 Application Identifiers to be correctly interpreted.

Ideally the scanner then passes the decoded data using the Symbology Identifier (]d2) to the processing system. If FNC1 is not in the first position, the scanner will output a different Symbology Identifier. ]d2 indicates that the decoded data came from a GS1 DataMatrix symbol and can therefore be processed according to the GS1 Application Identifier rules.

]d2 is a system feature and is never directly encoded into the GS1 DataMatrix symbol.

3.3.2 Transmission of data strings

The scanner does not normally contain any intelligence but simply transfers the string of characters read from the symbol to the Information System for further processing.

A typical example is below:

Figure 3‑3 Symbology identifier example

The data transmitted to the application software for the first FNC1 (See section 2.2.1 ), is the symbology identifier ]d2 and for the second FNC1, when used as a separator character is <GS> Group-Separator. The above example would result in:

]d201034531200000111719112510ABCD1234<GS>2110

This string of data is then passed to the processing system or, in some more sophisticated scanner/decoder devices, the string of data is already interpreted according to the GS1 Application Identifier rules (see section 2.2.3 )

0103453120000011 ; 17191125 ; 10ABCD1234 ; 2110

In other systems the data string may be transmitted in hexadecimal characters:

0000 5d 64 32 30 31 30 33 34 35 33 31 32 30 30 30 30 | ]d20103453120000 |

0010 30 31 31 31 37 31 39 31 31 32 35 31 30 41 42 43 | 0111719112510ABC |

0020 44 31 32 33 34 1d 32 31 31 30 0d 0a | D1234~2110~~ |

Finally in hexadecimal without spaces;

5d6432303130333435333132303030303031313137313931313235313041424344313233341d323131300d0a

Please note that, separator character <GS> is transmitted as a “~” character in the second example above.

This choice is made at the very detailed processing level – and is normally processed totally within a black box type device.

4 Symbol marking techniques

This section provides an overview of the main technologies and the main processes for printing GS1 DataMatrix. It summarises their individual strengths and weaknesses for various applications. It does not aim to compare or promote a particular technology.

The focus is mainly on technologies that can be used on-demand: that is to say, systems that can encode dynamic information such as batch numbers or serial numbers. Therefore, it does not detail other conventional techniques such as flexographic or offset which are excellent for printing static information (e.g. product identification).

Please also bear in mind that the technologies and materials for printing and marking GS1 DataMatrix are developing fast. It is therefore advisable to consult your local GS1 member organisation and technical partners to take advantage of the latest developments.

4.1 Basic software functions

4.2 Symbol marking technologies

4.3 Selecting the right symbol marking technology

4.4 General recommendations for symbol quality

4.5 Colours and contrast

4.6 Verification of symbol (data and print quality)

4.7 Recommendations when developing Application Standards

Software of some type will be required to generate GS1 DataMatrix symbols. The software can format the data into the syntax required by the printing device. Software can be purchased that is integrated into the printing device or that is external and separate from it.

4.1.1 Printing device independent software

In principle, this type of software can be used with any type of printing device or indeed several different ones simultaneously.

The concept is to generate information to be printed and transfer this to the printer either by:

■ Sending the print-file message to the printer, or,

■ Creating an image that can be reproduced

4.1.2 Software embedded in the printing device

This type of software is characterised by a printing device having a dedicated internal logic that directly generates the GS1 DataMatrix symbol to be printed.

This is particularly useful when the data contained and/or size and form of the symbol to be printed vary from one product to the next. Indeed, the computing time can be minimised by using software integrated with the printing device by, for example, having the device generate a unique number for each product (e.g., a serial number).

4.1.3 Selecting the right software

The exact choice of software will need to meet the individual business requirements.

In general terms the software must be capable of generating a GS1 DataMatrix symbol in full conformance to the ISO/IEC 16022 standard. Often a difficult area is the programming of FNC1 in the first position as each software supplier has (or has not) developed its own method to obtain the correct encoding in the form of codeword 232. It is worth ensuring the software has this feature. The software should also allow for special characters:

Many of the good software programmes provide a ‘wizard’ that helps to check and automate the encoding of data according to the GS1 standards (e.g., Application Identifiers, data formats, check digits, etc.).

This section only focuses on technologies that can be used on-demand.

The symbol marking technologies most suited to printing GS1 DataMatrix are:

■ Thermal transfer

■ Inkjet

■ Laser etch

■ Direct part marking (dot-peening, engraving, etc.)

The exact choice will primarily be made in terms of the available support material and exact business requirement.

Particular attention is required when specifying the X-dimension and the ability of the print substrate to support it. The target size of the X-dimension is likely to be an important consideration in the choice of printing system.

4.2.1 Thermal transfer

Thermal transfer printing is one of the most widely used technologies for printing on-demand barcode labels. The technology works through heat being transmitted onto a ribbon (a tape coated with specially designed ink) that then transfers the image to the label. Very good quality barcodes can be achieved when the labelling material and print ribbon are fully compatible.

The choice of ribbon to be used is therefore normally determined by the:

■ Substrate - its ability to absorb ink and its smoothness,

■ Marking system - print head configuration and the print speed

The normal print resolution for thermal transfer printers is between 4 and 24 dpmm (dots per millimetre), approximately 100 and 600 dpi (dots- per-inch).

A wide variety of thermal transfer ribbons are available and it is very important to match your ribbon selection to the printer. Print quality will also be influenced by heating energy, printing speed and pressure.

The quality of printed symbols must be checked at regular intervals. One of the main problem areas with thermal transfer printing is the risk of a ‘print-head burnout’ where one of the heating elements stops working so creating gaps.

4.2.2 Inkjet

Inkjet is a printing process that does not require contact between the printer and the substrate. The technology works by propelling tiny drops of ink onto the substrate to create the symbol. There are two main categories of inkjet printer:

■ Continuous Inkjet: A high-pressure pump creating a continuous stream of ink droplets that are then subjected to an electrostatic field. This results in a controlled, variable electrostatic charge that determines if the ink drop should be printed on the substrate or recycled (leaving a light area).

■ Drops on Demand: Printers in this family only use drops of ink that are required to print. It is particularly suited to high resolution printing.

The print head needs to be close to the substrate (some products can print from a distant as far as 20 mm) and it is suitable for printing on a variety of media and substrates.

Inkjet printing usually prints edges in an irregular shape. This is caused by the absorbency of the substrate and by the irregular shape of the single dots. Good quality symbols are possible when printing on a suitable substrate, using a high resolution printer and fast drying ink. The inkjet printer should be kept within the operating parameters recommended by the manufacturer.

Special attention must be paid to the consistency of the speed with which the object to be printed passes the print head. Precision is required to ensure quality symbols.

Example: A GS1 DataMatrix printed using Continuous Inkjet:

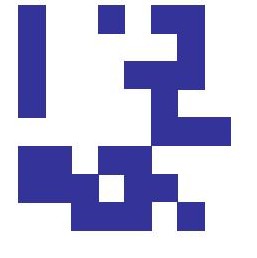

Figure 4‑1 Inkjet printed GS1 DataMatrix

4.2.3 Laser etch (Direct Part Marking - DPM)

Laser etch – or laser engraving – uses precisely controlled lasers to engrave or mark the barcode on the product. The high concentration of laser power burns or etches the symbol and this needs a computer using a series of mirrors and lenses to focus the laser. The process allows a product to be directly and permanently marked but is only suitable for “laserable” materials.

The power of the laser needs to be set based on the volume printing required as well as the speed of printing. The power must be adapted to substrates and commonly ranges from 10 to 100 watts.

Example: A GS1 DataMatrix printed using Laser:

Figure 4‑2 GS1 DataMatrix Laser symbol

4.2.4 Dot peen (Direct Part Marking - DPM)

The technology is used to directly mark the material and is particular suitable for solid materials (metals, plastics, wood, etc.…). It can be used for all the information to be marked on the item (text, date, logo, etc.) as well as the GS1 DataMatrix symbol. A small head – normally made from a very strong material such as tungsten – is computer controlled to make a defined series of identical punch marks in the surface of the substrate. The depth of marking can be carefully controlled to ensure all indents are identical making this technique particular suited for printing GS1 DataMatrix directly on items made of metal or other material with very hard flat surfaces.

Example: A GS1 DataMatrix printed using Direct Part Marking:

Figure 4‑3 GS1 DataMatrix dot-peen symbol

The technology chosen for a given application should take into account the internal environment including factors such as substrate.

![]() The table below gives an indication of the compatibility between the substrate (the material upon which the GS1 DataMatrix will be printed) and symbol marking technologies. In all cases, it is recommended to test and confirm that the technology will work in the real environment where it will be used. This testing should include all aspects of the technology including inks, varnishes, maintenance cycle, etc.

The table below gives an indication of the compatibility between the substrate (the material upon which the GS1 DataMatrix will be printed) and symbol marking technologies. In all cases, it is recommended to test and confirm that the technology will work in the real environment where it will be used. This testing should include all aspects of the technology including inks, varnishes, maintenance cycle, etc.

Table 4‑1 Substrate / Marking technology table

| Substrate | Paper | Corrugated fibreboard | Glass | Plastic | Metal | |

| Technology | ||||||

| Laser Etch | For specific colours or specific finishing | For specific colours or specific finishing | Under certain conditions | If contrast can be achieved or specific finishing | Painted or oxidised | |

| Thermal Transfer (on- demand) | Useful for adhesive labels | No | No | Plastic films | No | |

| YAG/Fibre Laser | Coloured background or specific finishing | No | Yes | Yes | No | |

| Ink Jet (on- demand)

| Yes | No | No | No | No | |

| Direct Part Marking | Film transfer | Film Transfer | No | Yes | Yes | |

■ Available space for printing: The physical size of the symbol and all related Human Readable Information must take into account the space available to print them. In general terms, larger symbols will have a better scanning and printing performance than smaller ones but many factors – including legally required safety information – will impact the space available for printing the barcode.

■ Printing speed: When printing symbols on-line (e.g., as part of the production line process for items), the speed of the overall product line will have a big influence on the choice of technology selected.

The technology chosen will also be impacted by external factors such as:

■ Sector norms and conventions (e.g., healthcare, automotive, aeronautical, etc.): Many sectors have norms and conventions for the use of GS1 DataMatrix in terms of quality, symbol location, required data (both encoded and in Human Readable Interpretation). These industry norms should be considered when selecting the symbol marking technology.

For example, in the healthcare sector, the user community has agreed on a permissible X-dimension for small healthcare products (see A ) .

■ Customer requirements: As in all business transactions, the needs of the customer should be taken into account. Some customers may impose a set of specifications as a requirement for doing business. These specifications may favour one technology over others. For example, by setting an extremely high minimum quality verification threshold (see section 4.6 ) the customer may in effect be imposing a given printing technology.

Within the open environment where GS1 standards are used, it is very important for all players to work to industry established standards. This creates a critical mass of particular usages and reduces overall costs as many competing technology providers work to meet the common requirements.

■ Regulatory requirements: In some highly regulated industries (such as healthcare or aerospace) and/or in some countries, regulations may be in place. The technology’s ability to meet these regulatory requirements will then be a key consideration when making a purchase.

Symbol quality is of great importance and should be included in any production quality control process. As a quick check the following should be confirmed with any technology supplier:

■ Full compliance to the ISO/IEC 16022 standard

■ The software is able to support GS1 Application Identifiers

■ Data Matrix ECC 200 (not older, obsolete versions of Data Matrix) is supported

■ The FNC1 is supported both as a start and separator character

As outlined earlier (see section 1.1 ) the size of the GS1 DataMatrix symbol can vary. In general terms, larger X-dimension symbols will have a better scanning and printing performance than smaller ones but many factors (available space, amount of data encoded, etc.) will influence the size of symbol.

It is of critical importance for the final quality of the printed symbol that the ability of the printer to achieve the selected X-dimension.

Note: the print-head individual element size will determine which X-dimensions can and cannot be achieved. For more information please refer to 2D Barcode Verification Process Implementation Guideline. The guideline is available at www.gs1.org.

Contrast is the technical name for the difference between the dark and light areas in a barcode and, in particular, how the difference is seen by the scanner. It is imperative that the printing process ensures that the scanner can discriminate clearly between the dark areas and light areas of the symbol.

Contrast is heavily impacted by the colour and reflectance of the substrate used. When implementing GS1 DataMatrix it is therefore necessary to think about the colours used for both substrate and inks (if used).

These simple recommendations should help selecting a good colour combination and achieving good symbol contrast:

■ Use of black (dark colours) and white (light colours) in printing is generally accepted as the best colour combination.

■ It should be noted that one feature of GS1 DataMatrix is that the colours can be reversed: light modules on a dark background or dark modules on a light background. When using this reverse/inverse image feature scanner/imager capability to read reverse/inverse images must be checked.

■ Dark areas should use solid dark colours (black, blue, or colours that contain a very high proportion of black).

■ Light areas should use bright and reflective colours (white, yellow or red (note some scanners use a red light therefore red appears ‘white’ to the scanner).

■ Intermediate colours or hues – those that appear neither light nor dark – should not be used

■ Certain substrate materials, particularly highly reflective metals, and highly reflective inks (e.g., gold or silver) should be avoided as the reflectance can ‘blind’ the scanner.

Some common contrast problems are caused by:

■ A bad choice of colours for the dark and/or light areas.

■ The use of a transparent background (known as ‘Opacity’)

■ A ‘blurring’ of the dark colours into the light area.

■ Excessive reflectance from very shiny or glossy surfaces.

This section highlights those parameters that can affect the overall symbol quality and how they can be checked or verified. It is important to stress that quality covers both:

■ Conformance of the encoded data (e.g., correct use of GS1 Application Identifiers, Check Digits, etc.)

■ Symbol print quality (e.g., according to ISO/IEC 15415).

Quality should not be seen as a simple check at the end of the process, but should be built into the development process with the appropriate conformance checks made at each stage. It is also important to verify that the final printed symbol meets the requirements of the appropriate application standard in terms of encoded data, print quality, symbol size, symbol location, etc.

4.6.1 ISO/IEC 15415 Barcode print quality test specification–2D symbols

4.6.1.1 Print quality testing methodology

(see the GS1 General Specifications – Barcode production and quality assurance)

ISO/IEC 15415 and the GS1 General Specifications define the methodology to test the print quality of printed GS1 DataMatrix symbols. This methodology is widely covered in 2D Barcode Verification Process Implementation Guideline. It is available at www.gs1.org. Under this methodology the symbol grade is only meaningful if it is reported in conjunction with the illumination and aperture used expressed as: grade/aperture/light/angle:

□ Angle: is an additional parameter defining the angle of incidence (relative to the plane of the symbol) of the illumination. It is only required in the overall symbol grade if is different from 45°. All GS1 Application Guidelines specify a 45° angle.

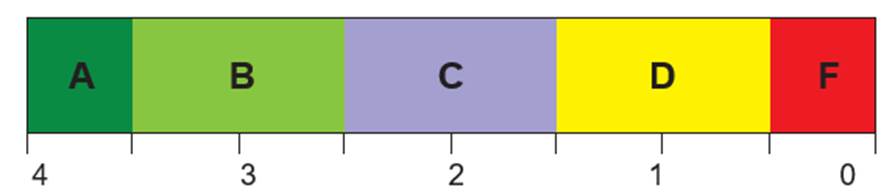

Grade: is the overall symbol grade as defined in ISO/IEC 15415. It is a numeric grade (4 being the best and 0 the worst). ISO/IEC 15415 was based upon – and is fully compatible with – an ANSI verification methodology. One of the main differences is that ISO/IEC 15415 uses a numeric grading structure, expressed up to one decimal place, while ANSI used a scale of A to F. The conversion between the two grading systems is summarised as:

Figure 4‑4 Symbol grade in ISO/IEC 15415

Aperture: is the aperture reference number defined in ISO/IEC 15416 (expressed in mils or thousandths of an inch)

Light: defines the illumination: a numeric value indicates the peak light wavelength in nanometres (for narrow band illumination); the alphabetic character W indicates that the symbol has been measured with broadband illumination (“white light”) but for GS1 Applications 670 is the norm.

Light sources for barcode scanning applications normally fall into two areas:

Narrow band illumination in either the visible or the infra-red spectrum, or broadband illumination covering a large part of the visible spectrum, sometimes referred to as “white light” although it may have a bias to a colour; a very few specialised applications may call for light sources of unusual characteristics such as ultra-violet for fluorescent symbols.

Multi-row barcode scanning almost always uses narrow band visible light, with light sources with a peak wavelength in the red part of the spectrum, between 620 and 700 nm. Infra-red scanning uses sources with peak wavelengths between 720 nm and 940 nm.

Two-dimensional matrix symbols are scanned under a variety of illumination conditions, with the most common being white light and, in a number of hand-held reading devices, the same visible red area of the spectrum as for linear and multi-row barcode symbols.

The most common light sources used for these purposes are:

Narrow band:

■ Helium-neon laser (633 nm) (multi-row barcode symbols only).

■ Light-emitting diode (near-monochromatic, at numerous visible and infra-red peak wavelengths).

■ Solid-state laser diode (most usually 670 nm) (multi-row barcode symbols only).

Broadband:

■ Incandescent lamp (nominally white light with a colour temperature in the range 2800 °K to 3200 °K).

■ Fluorescent lighting (nominally white light with a colour temperature in the range of 3200 °K to 5500 °K).

Example: A print quality test carried out with an aperture of 10 mils, a light source of 660 nm and at an angle of 45° gave the grade of 3.0(B). The results should be expressed as:

3.0/10/660

4.6.1.2 Parameters measured and their significance

ISO Symbol Grade: The overall ISO symbol grade is the most important parameter for communicating the print quality of a symbol. The scan grade is the lowest grade achieved for seven parameters which are Symbol Contrast, Modulation, Fixed Pattern Damage, Decode, Axial Nonuniformity, Grid Nonuniformity, and Unused Error Correction, with others specified for a given symbology or application. The overall ISO symbol grade is the arithmetic mean of the individual scan grades for a number of tested images of the symbol.

| Parameter | Significance |

| Decode | This is the first step in the verification and applies the reference decode algorithm - the set of rules/steps for decoding the symbol defined in ISO/IEC 16022 - to the elements seen by the verifier. If a valid decode results, the decode parameter passes and is given grade 4, otherwise it fails (grade 0). |

| Symbol Contrast | The Symbol Contrast is the difference between the highest and the lowest reflectance values in the profile – in simple terms the difference between the dark and light areas (including the Quiet Zones) as seen by the scanner. Symbol contrast is graded on a scale of 4 to 0. Figure 4-5 A symbol with very poor Symbol Contrast.

|

| Axial Nonuniformity | Axial Nonuniformity measures and grades (on the 4 to 0 scale) the spacing of the mapping centres and tests for uneven scaling of the symbol along the X or Y axis Figure 4-6 An Axial Nonuniformity problem

|

| Modulation | Modulation is related to Symbol Contrast in the sense that it measures the consistency of the reflectance of dark to light areas throughout the symbol Figure 4-7A Symbol with poor Modulation caused by irregular dark areas.

|

| Grid Nonuniformity | Grid Nonuniformity measures and grades (on the 4 to 0 scale) the largest vector deviation of the grid intersections, determined by the theoretical position prescribed by the reference decode algorithm and the actual measured result. Figure 4-8 A Grid Nonuniformity problem

|

| Unused Error Correction | Measures and grades (on the 4 to 0 scale) the reading safety margin that error correction provides. Unused error correction indicates the amount of available Error Correction in a symbol. Error Correction is a method of reconstructing data that is lost via damage, erasure of the symbol, or poor printing. 100% unused Error Correction is the ideal case. |

| Fixed Pattern Damage | Measures and grades (on the 4 to 0 scale) any damage to the Finder Pattern, Quiet Zone and Clock Track in the symbol. The example below highlights the areas of the symbol that are tested under these parameters by showing the various defects: Figure 4-9 Fixed Pattern Damage

The example shows defects in the L-Shaped Finder Pattern and in the Clock Track: L1: Irregular L-Shaped Finder Pattern on the left L2: Irregular L-Shaped Finder Pattern on the lower edge QZL1: Note: the issue of L1, also means the Quiet Zone on the left is irregular QZL2: Note: the issue of L2, also means the Quiet Zone as the bottom is irregular OCTASA (Overall Clock Track and Adjacent Solid Area): Issues in the Clock Track (the dotted line opposite the L-Shaped Finder Pattern) can take one of three forms: CTR (Clock Track Regularity test): A pass/fail test on the elements that make up the Clock Track; SFP (Solid Fixed Pattern test): A graded measure (on a 4 to 0 scale) of the dark and light areas of the Clock Track TR (Transition Ratio). A graded measure (on a 4 to 0 scale) of the sequencing of the dark and light areas of the Clock Track Average Grade: In addition to the assessment of the individual tests above (which are very useful for symbol diagnostics), an Average Grade can be reported that takes into account the cumulative effect of any damage. It is calculated using the results of L1, L2, QZL1, QZL2 and OCTASA together. This is particularly useful as, when combined, many small errors may cause scanning problems. |

| Print growth | Print growth is not a graded parameter but is a very informative measure for the purposes of process control. It is a measure of how symbols may have grown or shrunk from target size. If the growth or shrinkage is too large, then scanning performance will be impacted. Print growth may be measured and evaluated independently on both the X and Y axis to assess both horizontal and vertical growth. The two examples below show: Figure 4-10 Too much Print Growth

Figure 4-11 Print Loss

|

4.6.2 Other print quality standards

ISO/IEC 15415 and ISO/IEC 29158:2011 are for measuring the print quality of GS1 DataMatrix symbols. However, there are number of other emerging quality standards for GS1 DataMatrix including, AS9132 and ISO/TR 29158. They were developed primarily for direct part marking (DPM) and their main features are described below for information purposes only.

4.6.2.1 AS 9132

AS (American Standard) 9132 deals with general print quality for part marking. It is referenced by a number of aeronautical companies that require 2D symbols to be used by their suppliers. The main print quality features are:

|

Angle of distortion | Figure 4-12 Angle Distortion

This figure above shows how distortion is measured. The standard allows a distortion up to 7°. |

|

Filled cells | This is a measure, expressed as a percentage of the filled cells versus the ideal as given by symbology specifications Figure 4-13 Filled Cells

This example shows marked cells which have been filled (when they should not have been) as a result of the print process used. The error correction capabilities of GS1 DataMatrix allow such symbols to be decoded if the error is not too large. |

|

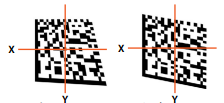

Centre point discrepancy | Slight discrepancy can occur between the actual centre of a cell and its theoretical position. Centre Point Discrepancy measures any deviation in this area: Figure 4-14 Centre Point Discrepancy

|

|

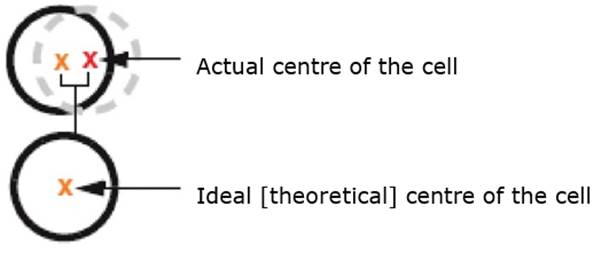

Elongation | Figure 4-15 Elongation

Elongation of individual cells may occur due to a variety of printing conditions. Elongation is measured as a deviation from the perfect circle. The standard allows for a 20% difference between D and d. |

|

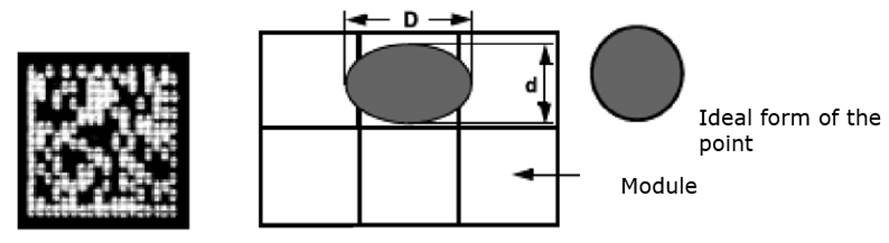

Number of dots per element | Figure 4-16 Number of dots per element

For many printing technologies each X-dimension is made up of a number of dots. When viewed under magnification, these dots (or pixels) can be measured. The example above shows four GS1 DataMatrix Cells each made up of 10x10 pixels. |

|

Quiet Zone | Figure 4-17 Quiet Zones of a GS1 DataMatrix A Quiet Zone with a minimum width of one module (X) is required all around the symbol as shown in the image above. If the Quiet Zone is less than one module (X) it will fail ISO/IEC 15415 verification. It can also be measured for diagnostic purposes. The contrast is also a parameter of ISO/IEC 15415 verification, (see section 4.5 ) |

4.6.2.2 ISO/IEC TR 29158 Direct Part Mark quality guideline

AIM Global (the Association for Automatic Identification and Mobility) has acknowledged that ISO/IEC 15415 Print Quality Specifications are not sufficient for measuring the quality of GS1 DataMatrix symbols printed using Direct Part Marking (DPM) technologies. The AIM Global Technical Symbology Committee has developed an AIM Global Document and submitted to ISO/IEC TR 29158, Direct Part Mark (DPM), Quality Guideline for this purpose. The guideline is available at the ISO Global Website www.iso.org.

Apart from the other parameters listed above, key parameters within the ISO/IEC TR 29158 document include Modulation within a cell and Minimum Reflectance (> 5 %).

| Modulation within a cell | Figure 4-18 Modulation within a Cell

As the name suggests, modulation within a cell requires uniformity of the reflectance of light and dark areas within one cell of the symbol. The example above highlights the type of printing problem that can lead to modulation within a cell. |

4.6.3 Possible causes of low grade

| Parameter | Possible causes of low grades | Example | |

|

Symbol Contrast |

Low background or light area reflectance, due to: ■ Poor choice of substrate (e.g., dark background) ■ Glossy laminate or overwrap High dark module reflectance, due to: ■ Unsuitable formulation or colour of ink ■ Insufficient ink coverage (e.g., on-over- lapping dots) Inappropriate angle of illumination particularly for symbols printed using Direct Part Marking (DPM). | Figure 4-20 Symbol Contrast

| |

|

Decode |

Many factors can cause the symbol to fail to decode. A major failure in any of the tested parameters or software errors in the printing system should be checked first. |

| |

|

Unused Error Correction | Physical damage due to: ■ Scuffing ■ Tearing ■ Deletions Bit errors due to print defects Excessive print Growth Local deformation Misplaced Modules |

| |

|

Modulation |

Print growth or loss Verifier aperture set too large for X-dimension used Defects - print spots or voids (see defects) Irregular substrate reflectance Variation in ink coverage Show-through (often caused by printing on a transparent background) Transparency | Figure 4-21 Print Growth

Figure 4-22 Print Loss

| |

|

Fixed Pattern Damage |

Spots of ink or other dark marks on the background Voids in printed areas Faulty print head elements or other print setup fault. Verifier aperture set too large for X-dimension used | Figure 4-23 Fixed Pattern Damage

| |

|

Axial Nonuniformity |

Mismatch of transport speed in printing with symbol dimensions Printing software errors Verifier axis not perpendicular to symbol plane | Figure 4-24 Axial Nonuniformity

| |

|

Grid Nonuniformity |

Problems with the speed during printing (accelerations, decelerations, vibration, or slippage) Variable distance between the print head and the print surface Verifier axis not perpendicular to symbol plane | Figure 4-25 Grid Nonuniformity

| |

|

Print Growth/Loss | Largely dependent upon the exact print process used. Factors may include: ■ Ink absorbency of the substrate ■ Dot size (Inkjet and DPM) ■ Incorrect thermal print head settings |

| |

4.6.4 The verification process

The 2D Barcode Verification Process Implementation Guideline explains the practical implications of verification GS1 2D barcodes. It is available at www.gs1.org.

The primary function of any barcode is carrying data from the point at which it is originated to the point at which the data has to be captured. Verification aims to check that the symbol is able to fulfil this function by ensuring compliance with the appropriate standard.

To be reliable, the verification process must be:

■ Fully compliant and in accordance with standard ISO/IEC15426-2,

■ Performed by a qualified operator.

■ Cover both the print quality aspects (explained below) and the data content requirements explained by application guidelines (see section 2 ).

For each of the parameters tested (see section 4.6.1.2 ) the lowest achieved grade is taken and this is the Overall Symbol Grade. The verification should be performed under laboratory conditions using the required aperture, light and angle as described in ISO/IEC 15415.

During the verification testing, the intended area of application should be considered (for example, for healthcare applications a certain data content may be required

Note: It is important not to confuse scanning with verification. At best, scanning a symbol can be used as a “go/no-go” test of whether a symbol can be read by that particular scanner.

Verification provides diagnostic information about any problem with a symbol and provides a high level of confidence that the symbol will scan in an open environment within its intended area of application. However, it should be noted that some symbols that fail verification will still be readable by some barcode readers.

To control print quality during production, three main approaches can be taken:

1. Integrate barcode verification as part of the normal quality control procedure

2. Perform online scanning of all symbols to ensure readability

3. Perform sample scanning at periodic intervals during production

These three approaches are complementary and should be implemented according to overall quality requirements of the production line. However, there may be practical difficulties in scanning each of the printed symbols given the speed of some production lines and testing itself should also be used to ensure systems are maintained at the correct level by, for example, picking up a trend toward less high quality symbols.

Within the recommendations of the standards it is possible to check print quality online with one check from a fixed position.

The results should be recorded and reported in the same way as a for a general verification report (see section 4.6.1.1 ):

grade/aperture/light/angle

The size of the measuring aperture affects whether voids in the symbol will be ignored during the verification process. Therefore, the measuring aperture must be selected with reference to the range of nominal module size and expected scanning environment. An aperture that is too small will detect unintentional voids, or gaps between elements of the symbol that would lead to low grades or undecodable symbols. On the other hand, a measuring aperture that is too large will blur individual modules, resulting in low modulation, and may prevent the symbol from being decoded.

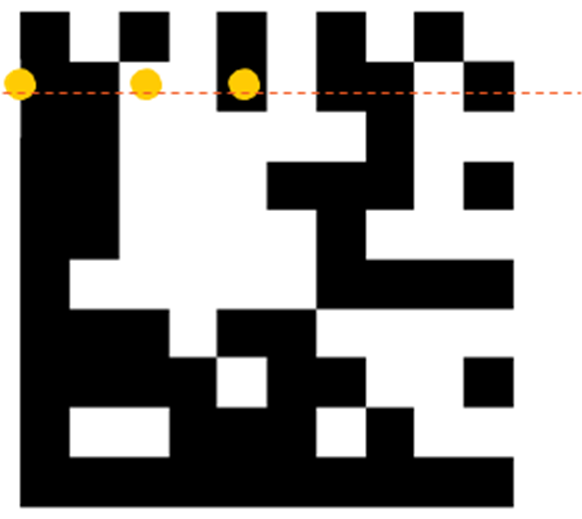

In general, the larger the aperture, the larger the acceptable size of spots and voids. Conversely, the smaller the aperture, the smaller the acceptable module size that can be read. Therefore, a successful application specification must select a measuring aperture that will predict the readability of both the largest and smallest module size symbols. The ideal theoretical size for the measuring aperture is between 40% and 80% of the maximum size of the X-dimension used in the symbol. However, as stated before, any application guideline will have to be taken into account. In order to demonstrate aperture, the aperture used to verify the symbol is represented by a yellow dot in the figure below.

Figure 4-26 Aperture on a symbol

It is also useful to note on the verification report:

■ An indication of the verifier used (name and serial number)

■ The date of the test and the name of the operator who performed it

■ Comments on the substrate and, if possible, the print process used (in case either is changed at some point in the future, thus invalidating the test report)

4.6.5 Selecting a verifier

Firstly, compliance with the appropriate standards is a pre-requisite. The four standards GS1 General Specifications, ISO/IEC15426-2, ISO/IEC15415 and ISO/IEC 16022 should be supported by the verifier.

Secondly, the verifier must be capable of consistent performance (e.g., the same symbol will yield the same result when tested). Initially, this is achieved by the factory set-up of the verifier. However, to maintain this consistency the verifier should be calibrated using a GS1 Calibration Conformance Test Card in line with the manufacturer’s instructions.

Other features that should be considered, include:

■ The pixel size of the camera used should be suitable for the size of the GS1 DataMatrix symbols being tested

■ What wavelength light source does it use? The GS1 General Specifications require 670 nm.

■ What measuring aperture(s) is/are available?

■ What form of output is available (e.g., LEDs, display, printout of details, PC connection, etc.)?

■ Fuzzy logic should be avoided in verifiers. While some aggressive scanners use fuzzy logic to try and read poor quality barcodes, such features should be avoided in verification equipment whose goal is to help improve barcode quality.

■ The manufacturer’s control / re-calibration requirements.

Independent of the verification equipment used, extensive studies have shown that operators of verifiers require proper training. Additionally, in order to achieve consistent results, verifiers require regular calibration by using the GS1 Calibrated Conformance Standard Test Card for GS1 DataMatrix from GS1 US, in accordance with manufacturer recommendations.

Any Application Standard for GS1 DataMatrix must set the clear, achievable and independently measurable print quality requirements. Users of the Application Standard are likely to make their choice of printing technology based upon the print quality requirements stated.

In terms of print quality an Application Standard must, at minimum, specify:

■ The methodology for measuring the print quality. For GS1 ISO/IEC 15415 is considered the de-facto methodology

■ A minimum acceptable Print Quality Grade as per the methodology used. For example, grade 1.5 according to ISO/IEC 15415

■ Depending upon the exact Application Standards, it may include:

□ Symbol location guidelines

□ Minimum and Maximum X-dimensions

□ The print process used to create the symbol (e.g., printed labels may create a perfect symbol but will not be suitable for products that require heat-sterilisation)

Please refer to the current version of GS1 General Specifications for more information on application standards.

A Annexes

A.1 GS1 size recommendations for symbols using GS1 DataMatrix

Some extracts of the GS1 General Specifications (version 16) are given below.

Please refer to the current version of GS1 General Specifications System Symbol Specification Tables 6, 7, 8, 9, 10 and 11 for the normative specification.

A.1.1 Symbol specification table 6 - Regulated healthcare non-retail consumer trade items not scanned in general distribution

| Symbol(s) specified | X-dimension | Minimum symbol height for given X | Quiet Zone | Minimum quality specification | ||||||

|

| Minimum | Target | Maximum | For minimum | For target | For maximum | Left | Right |

| |

| GS1 DataMatrix (ECC 200) (*) | 0.254 (0.0100") | 0.380 (0.0150") | 0.495 (0.0195") | Height is determined by X-dimension and data that is encoded | 1X on all four sides | 1.5/08/660 | ||||

| (*) | 2D X-dimension - Optical effects in the image capture process require that the GS1 DataMatrix symbol be printed at 1.5 times the equivalent printing X-dimension allowed for linear or Composite symbols. | |||||||||

A.1.2 Symbol specification table 7 - Direct part marking

| Symbol(s) specified | X-dimension | Minimum symbol height for given X | Quiet Zone | Minimum quality specification |

| ||

|

| Minimum | Target | Maximum | For minimum, Target and Maximum X-dimension |

|

|

|

| GS1 DataMatrix | 0.254 (0.0100”) | 0.300 (0.0118”) | 0.615 (0.0242”) | Height is determined by X-dimension and data that is encoded | 1X on all four sides | 1.5/06/660 Note 3 | For direct marking of items other than medical devices |

| GS1 DataMatrix Ink Based direct part marking | 0.254 (0.0100”) | 0.300 (0.0118”) | 0.615 (0.0242”) | Height is determined by X-dimension and data that is encoded | 1X on all four sides | 1.5/08/660 Note 3

| For direct marking of medical devices such as small medical / surgical instruments |

| GS1 DataMatrix direct part marking - A Note 2 | 0.100 (0.0039”) | 0.200 (0.0079”) | 0.300 (0.0118”) | Height is determined by X-dimension and data that is encoded | 1X on all four sides | DPM1.5/04-12/650/(45Q|30Q|30T|30S|90) Note 5 | For direct marking of medical devices such as small medical / surgical instruments |

| GS1 DataMatrix direct part marking - B Note 2 | 0.200 (0.0079")

| 0.300 (0.0118”) | 0.495 (0.0195") | Height is determined by X-dimension and data that is encoded | 1X on all four sides | DPM1.5/08-20/650/(45Q|30Q|30T|30S|90) Note 5 | For direct marking of small medical / surgical instruments |

These notes have been taken from the GS1 General specifications. Please refer to the current version of GS1 General Specifications System Symbol Specification Table 7 for the normative specification.

Note: The largest X-dimension in a given range that will allow a symbol with the needed data content to fit within the available marking area should be used to maximise marking and reading performance (depth of field, tolerance to curvature, etc.).

The angle is an additional parameter defining the angle of incidence (relative to the plane of the symbol) of the illumination for direct part marking verification. It SHALL be included in the overall symbol grade when the angle of incidence is other than 45 degrees. Its absence indicates that the angle of incidence is 45 degrees. See ISO/IEC 15415 and ISO/IEC TR 29158 (AIM DPM).

In small instrument marking, mixed marking technologies used within the same scanning environment should be avoided to ensure highest reading performance. Laser etching is recommended for small instrument marking.

![]() Note 1: Optical effects in the image capture process require that label based GS1 DataMatrix and GS1 QR Code symbols be printed at approximately 1.5 times the equivalent X-dimension allowed for linear symbols in the same application.

Note 1: Optical effects in the image capture process require that label based GS1 DataMatrix and GS1 QR Code symbols be printed at approximately 1.5 times the equivalent X-dimension allowed for linear symbols in the same application.

![]() Note 2: There are two basic types of non ink based direct part marks, those with “connected modules” in the “L” shaped finder pattern (GS1 DataMatrix direct part marking – A) created by DPM marking technologies such as laser or chemical etching and those with “non connected modules” in the “L” shaped finder pattern (GS1 DataMatrix direct part marking – B) created by DPM marking technologies such as dot peen. Due to the marking technologies and characteristics of reading they each have varied ranges of X-dimensions and different quality criteria recommended and may require different reading equipment.