Release 2.0, Ratified, Aug 2017

GS1 Global Traceability Standard

GS1's framework for the design of interoperable traceability systems for supply chains

- 1 Introduction

- 2 Traceability and the importance of standards

- 3 Traceability data and traceability systems

- 4 Key enablers for interoperable traceability systems

- 5 Key requirements for interoperable traceability systems

- 6 Glossary

- 7 References

- A Summary of interoperability requirements

- B Data management responsibilities

- C Getting started

- D Sector examples

- Contributors & Change Log

Contents

- 2.1 Business drivers

- 2.2 The need for unique identification

- 2.3 The need for traceability data

- 2.4 The need for interoperability and standa...

- 2.5 GS1 standards – key enabler for interope...

- 3.1 Traceability data within an organisation

- 3.2 Traceability data across supply chains

- 3.3 Managing traceability data

- 3.4 Traceability systems

- 3.5 Traceability systems in action: An examp...

- 4.1 Identification of objects, parties and l...

- 4.2 Automatic identification and data captur...

- 4.3 Sharing traceability data

- 4.4 The traceability solution ecosystem

- 5.1 Prerequisites

- 5.2 Identification requirements (including s...

- 5.3 Automatic data capture and identificatio...

- 5.4 Data recording requirements (relation da...

- 5.5 Data sharing requirements

- 5.6 Roles and responsibilities

1 Introduction

1.1 Objective

1.2 Scope

1.3 About GTS version 2

1.4 How to use this document?

The objective of the GS1 Global Traceability Standard (GTS) is to assist organisations and industries in the design and implementation of traceability systems based on the GS1 system of standards. At a strategic level, this standard aims to provide key insights and knowledge for organisations or industries that are developing long-term traceability goals.

Traceability is the ability to trace the history, application or location of an object [ISO 9001:2015]. When considering a product or a service, traceability can relate to:

■ origin of materials and parts;

■ processing history;

■ distribution and location of the product or service after delivery.

GS1’s approach to enabling supply chain traceability is focused on the use of open standards to provide visibility of objects that are relevant to supply chains. This document is intended to help organisations and industries to achieve global supply chain traceability by:

■ Providing a methodology for organisations to use when developing requirements for the design of traceability systems that fit their needs and objectives.

■ Serving as the foundational starting point for sector-specific, regional and local standards and guidelines.

■ Enabling successful and interoperable communication across supply chains by providing consistent ways to identify traceable objects and to create and share standards-based data about the movements or events of those objects over the course of their lifetime.

■ Enabling scale and adoption by applying existing and proven standards, and so avoid fragmented approaches to use cases beyond traceability.

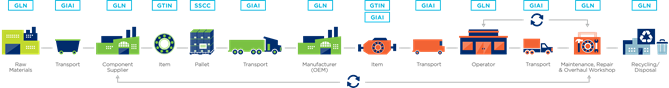

The GS1 Global Traceability Standard is intended for use across end-to-end supply chains and is relevant to all events that span the lifecycle of a traceable object, including:

■ The transformation and processing of raw materials, ingredients, intermediate products, components and components into the product.

■ Aggregation and disaggregation of products and linkage to assets (e.g., returnable assets).

■ Transport and distribution, including cross-border trade.

■ The maintenance, repair and overhaul operations across multiple cycles of usage or service of the product.

■ Consumption of products, including dispensing and administering.

■ The disposal and destruction of the product and the recycling of materials.

This document assumes that each individual organisation will have its own objectives when establishing the traceability systems and tools that drive their business. To succeed, each individual organisation will need to ensure that their systems are interoperable with systems of other organisations across their supply chains.

This document focuses on the data management aspects of traceability. It identifies and references the necessary requirements for capturing and sharing data using a simple model that works across known and trusted chains of custody or ownership. Traceability data is captured and shared across the “who, what, when, where and why” dimensions, in order to provide applications with sufficient business context to effectively use the data.

It also provides a foundation to enable data sharing across more complex supply chains, where parties need to find and retrieve information from companies that are not their direct trading partners and where trust may need to be established before data can be shared.

This document is sector and product neutral. The principles can be applied to supply chains across many sectors, including food and beverage, apparel, pharmaceuticals, medical devices, humanitarian logistics, technical equipment and components.

This document is also designed to be technology neutral. It is based on the foundational principles that are at the heart of the GS1 system of standards: Identify – Capture – Share. These foundational principles are used to explain how the GS1 system of standards can be used to enable traceability solutions. The document references a variety of data capture and data sharing technologies and related GS1 standards, including GS1 barcodes, EPC/RFID, GDSN, EDI and EPCIS.

The GS1 Global Traceability Standard does not aim to compete with other international standards that address traceability requirements such as those from ISO, those benchmarked by the Global Food Safety Initiative (GFSI) or other certification schemes but rather complements and completes them. Where these standards define “what” should be done, the GTS helps companies and organisations to understand “how to” meet these requirements using standardised traceability data.

GTS version 1 established the foundation for standards-based traceability systems by addressing the needs for:

■ globally unique identification of products, locations and parties;

■ labelling of all products and levels of packaging;

■ data capture and recording;

■ enabling access to the data;

with clearly defined responsibilities along the entire value chain.

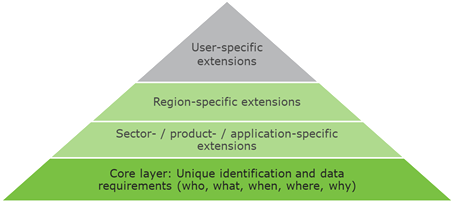

This second version of the GTS builds on the foundation established in version 1. In GTS version 2 a layered approach to traceability is introduced, in order to better suit the variety of traceability needs of increasingly dynamic supply chains and in order to embrace all capabilities offered by today’s information technologies.

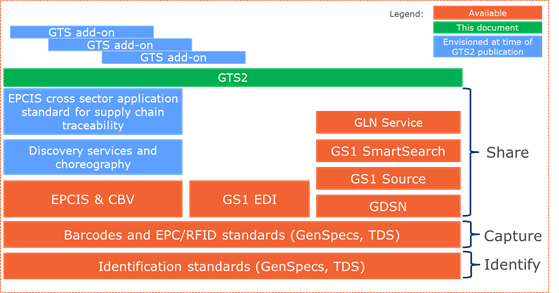

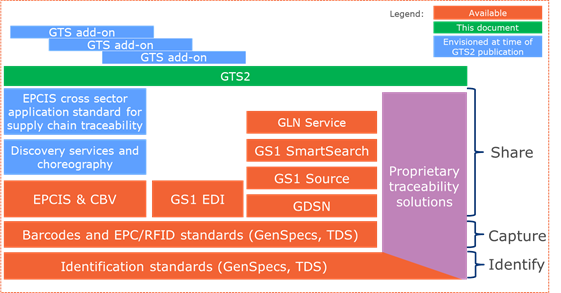

Figure 1‑1 GTS version 2

GTS2 is a generic document that builds on the GS1 standards for identification, data capture and data sharing. As shown in the figure, it is expected that additional standards and guidelines will need to be developed to enhance the GS1 standards.

Furthermore, the figure illustrates that GTS2 is expected to serve as a foundational reference document that will be augmented by sector-, industry-, domain-, product- and region-specific standards and guidelines. It is expected that this approach will ensure fast development of materials relevant to newly-identified business challenges.

![]() Note: As a first step a GTS implementation guideline will be developed (see appendix C).

Note: As a first step a GTS implementation guideline will be developed (see appendix C).

This document is intended for use by organisations of any size and for all supply chain parties and stakeholders. If you or your organisation have a need to access or share traceability data, this document will be a relevant reference for you.

■ Section 2 provides an overview of the GS1 traceability framework.

■ Section 3 goes deeper into the traceability data management aspects, and provides a generic example.

■ Section 4 explains how GS1 standards enable the creation of interoperable traceability systems.

■ Section 5 defines the key requirements for interoperable traceability systems.

■ Appendix A contains a summary of the interoperability requirements.

■ Appendix B provides an overview of the data management responsibilities.

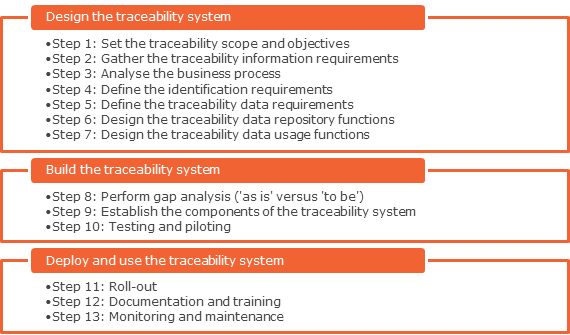

■ Appendix C describes a step-by-step method for the design and implementation of traceability systems.

■ Appendix D provides sectorial examples and references to GS1 resources.

■ Appendix E contains a list of people and organisations that contributed to this document.

2 Traceability and the importance of standards

2.1 Business drivers

2.2 The need for unique identification

2.3 The need for traceability data

2.4 The need for interoperability and standards

2.5 GS1 standards – key enabler for interoperability

The importance of data

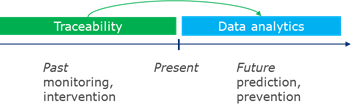

Traceability enables access to relevant data so that data can be analysed and decisions can be made. Data accessibility is key to drive speed of response and precision of analysis. It involves gathering, storing, and reporting detailed information about every important event throughout supply and production. That information can then be used in many different ways to improve operations or to resolve seemingly unrelated challenges.

Traceability data can be leveraged for much more than crisis-resolution. Data and related methods such as data analytics have become one of the most important ways for organisations to control and proactively monitor their supply chains.

Figure 2‑1 Traceability - enabling better decision making

![]() Note: Traceability data will not be the only source for effective data analytics. Various other sources, such as weather information, geographic data, demographic data, will be applied.

Note: Traceability data will not be the only source for effective data analytics. Various other sources, such as weather information, geographic data, demographic data, will be applied.

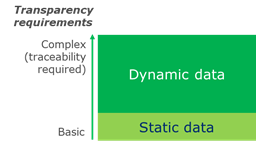

Transparency, which refers to the need to ensure visibility and access to accurate information across supply chains (inclusive of consumers), is often an important driver for traceability projects. Some transparency requirements may be fulfilled by using static data about customers, suppliers, products and production conditions. Requirements that are more complex will require static data as well as dynamic data related to the actual supply chain events and transactions that occurred, i.e. traceability. See section 3.3 for more information on traceability data.

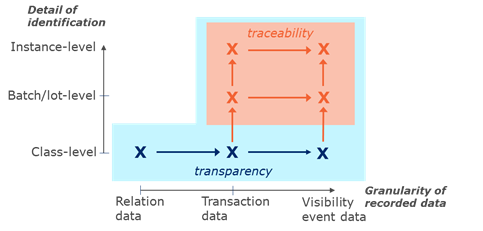

Figure 2‑2 Transparency, traceability and required data

Market pressures and regulatory demands

The supply chains of today are long and complex. They often intersect with a multitude of other supply chains, making traceability a multi-party and multi-chain challenge.

Market pressures and emerging regulations are critical drivers of traceability. A complicating dimension to traceability is compliance with varying and evolving regulations. In today’s global economy, supply chain traceability involves complying with multiple jurisdictions for each country and region involved in the supply chain.

As a result, each organisation may face a multitude of internal and external traceability requirements. This document is designed to ensure that the basic data sharing needs of these complex and long supply chains are explained in a way that is relevant to all.

Cross-functional

Because the sharing and use of traceability data can impact so many aspects of business operations, it should be no surprise that traceability tools and solutions are relevant across many functions and departments in an organisation, including but not limited to:

■ Quality & safety teams (risk management, recall readiness, audits, management of errors and incidents, expiry date management, stock rotation).

■ Compliance teams that are concerned with regulation and organisational requirements.

■ Consumer-facing teams that need to share relevant information.

■ Internal teams that are tasked with fighting counterfeiting, enabling supply chain security or brand protection.

■ Social responsibility teams focused on ethical and environmental topics.

■ Product life cycle management teams.

■ Teams responsible for transport and logistics.

■ Systems development and management teams.

People responsible for such a variety of functions will often have different perspectives on the needs of traceability systems and tools. All of these different perspectives are important, and this document aims to build a common understanding of needs by:

■ Creating a common language when talking about the data management aspects of traceability

■ Defining principles for the creation of interoperable traceability systems that can serve the needs of all these stakeholders

At the heart of any traceability system is the identification of traceable objects.

A traceable object is a physical or digital object for which there is a need to retrieve information about its history, application, or location. Examples of traceable objects include products (e.g., consumer goods, medicines, electronic devices), logistic units (e.g., palletised goods, parcels) and assets (e.g., trucks, vessels, trains, fork lifts).

For the physical identification of traceable objects, generally three main levels of identification can be distinguished (see section 4.1.1 for more information):

■ Class-level identification, where the object is identifiable by its product / part ID, enabling it to be distinguished from different kinds of products or parts.

■ Batch/lot-level identification, where the product / part ID is extended with a batch/lot number, limiting the number of traceable objects with the same ID to a smaller group of instances (for example, items produced at the same time).

■ Instance-level identification, where the traceable object is identified with a serialised ID, limiting the number of traceable objects with the same ID to one individual instance.

The objectives of the traceability system and the supply chain itself are key criteria to determine the right level of identification. For example, products and ingredients associated with high risks will always be identified at batch/lot- or instance-level.

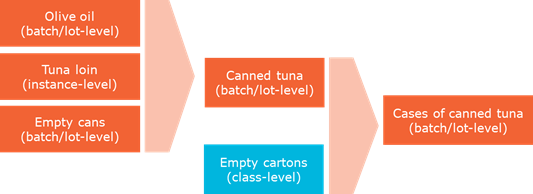

Companies will often apply a combination of identification levels. This is for example a common practice in transformation events arising in manufacturing, where the inputs in a manufacturing process include primary and secondary ingredients / materials. Taking the example of making canned tuna (see figure 2-3), primary ingredients / materials would comprise tuna loin, olive oil and cans, whereas empty cartons (in which the cans are packed into) would belong to secondary materials.

Figure 2‑3 Example of combination of identification levels

![]() Note: The empty cartons are shown in a different colour, since they are identified on class-level. This provides transparency but no real traceability. See also section 3.3.2 .

Note: The empty cartons are shown in a different colour, since they are identified on class-level. This provides transparency but no real traceability. See also section 3.3.2 .

Another example is the combined use of instance-level and batch/lot level on the same product: Each individual product gets a serialised ID, but the distribution units (e.g. outer cases) are identified on batch/lot-level for use by the supply chain and logistics systems of supply chain partners.

The time and cost to implement will vary greatly for each identification level. There is no ‘one size fits all’, and coordination with supply chain partners is essential when defining the identification levels that your organisation (and your supply chains) will require.

Traceability systems are powered by traceability data. Traceability data is generated through execution of a variety of business processes carried out by each organisation.

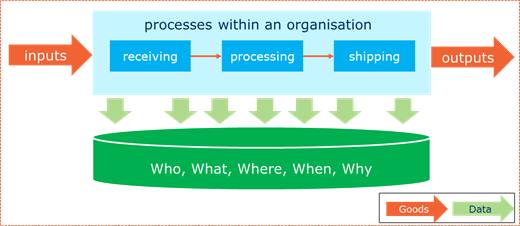

Figure 2‑4 Generation of traceability data - single company view

Each time a traceability-relevant process is executed in any organisation, traceability data is generated. This data provides business content to applications that use the data, and includes information that spans five important dimensions: Who, What, Where, When and Why.

■ Who: Which parties are involved?

Uniquely identified entities involved in the handling, custody or ownership of the objects moving through the supply chain. Where there is a need to distinguish the entity and their role in the process, it is valuable to include this.

■ What: What is the primary object being traced? Which related objects need to be traced?

Uniquely identifying objects that move through the supply chain is critical. These may be individual products as well as shipments of products. They may also include other physical or virtual objects such as transport means, equipment (including returnable transport items) and documents.

■ Where: Where did these movements or events take place?

Uniquely identified locations are critical to understanding the path an object takes across a supply chain. It may be a manufacturing site, a specific production line, a warehouse, a field, an ocean, a point of sale, a hospital, ship or rail car.

■ When: When did a movement or event that included that object occur?

The date, time and timezone when a specific event occurred provides the timeline of an object’s movement through the supply chain.

■ Why: What happened? What business process was happening at the time the event took place? What business transactions were taking place? Why was the object at that location at that time?

This tells the story of the object. It provides the business context around the events that have occurred. Shipping and receiving events represent changes in a chain of custody or ownership, while a dispensing event may indicate that a particular medicine was given to a patient. In manufacturing, transformation events represent when one or more ingredients were irreversibly combined to create one or more new outputs or products.

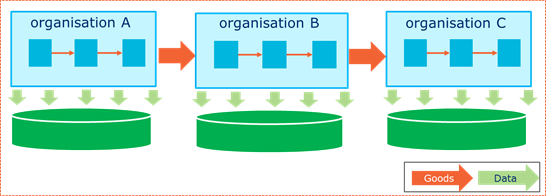

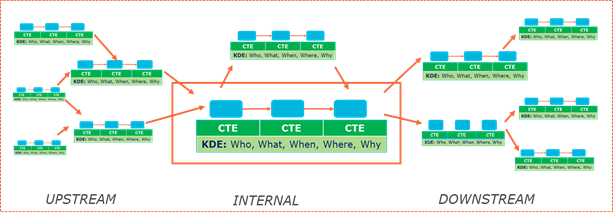

When we extend the view to a full supply chain, it becomes clear that each organisation will manage its own set of traceability data. In order to achieve end-to-end supply chain traceability, it will be necessary to access and combine data from multiple organisations.

Figure 2‑5 Generation of traceability data - supply chain view

An organisation’s traceability system will need to support a multitude of applications and use cases, from risk management to supply chain efficiency, regulations, sustainability, and consumer trust or brand integrity. It should be adaptable, because needs will evolve over time. It should leverage investments based on proven technologies and make use of what is already in place (e.g., logistic labels, barcode scanners) within each company and/or its trading partners as much as possible. Solutions should also enable easy integration with new system components.

A system that is implemented to meet internal traceability requirements may not be able to interoperate with systems of other parties in the supply chain. In order to ensure an appropriate level of interoperability, organisations will need to ensure that their systems are all built on a common set of standards. This does not mean that all actors in the supply chain need to use the exactly the same systems, but their systems will need to be able to support standardised data.

Variety of objectives and requirements

Individual companies have different objectives and needs when implementing traceability solutions. These differences are attributable to many factors, including product, supply chain role, regulatory and business environments, cost/benefit strategies and available enabling technologies.

In addition, many products cross geographic borders at least once in their lifecycle, subjecting them to multiple regulations, which can include mutually inconsistent requirements.

In order to realise the ultimate goal of end-to-end supply chain traceability, all partners of a specific industry or supply chain must use a foundational set of standards.

Variety of solutions and tools

Various information technologies and tools are available on the market to support traceability implementations. Commonly, multiple system components need to work together to deliver an overall system. These may include a system for managing product identification and master data, one or more solutions for automatic identification and data capture (AIDC) and other systems to capture transactional or event data about a product’s path through the supply chain.

Parties in a supply chain may also have different levels of technical maturity. They may have chosen different technologies, or may have implemented the same technology in different ways (using different software or platforms).

Standards-based systems and components are, to a certain level, naturally interoperable with other systems and components that conform to the same standards.

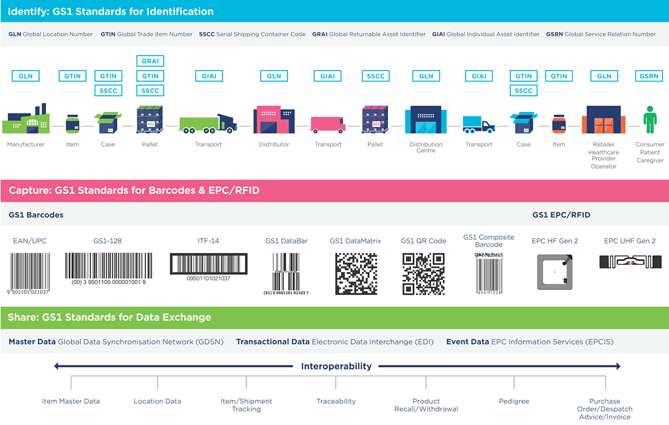

GS1 system of standards

The GS1 system of standards provides a comprehensive set of standards to identify, capture and share information about objects throughout their lifecycle, providing the core foundation for interoperability:

1. Supply chain partners identify business objects and locations using standardised identifiers.

2. Supply chain partners capture an object’s identity and any additional attributes (e.g. the expiry date) that have been encoded in a standard manner in a data carrier (barcodes, RFID). This ensures the object can be read automatically and consistently throughout the supply chain. Thereby, also the time (when), location (where) and other data (who and why) are recorded.

3. Once supply chain partners are using a common language for identification and data capture, the gathered data is refined and enhanced with business context, to transform it into data that can be shared using standardised semantics, in a standardised format, and using standard exchange protocols.

Figure 2‑6 The GS1 system of standards

![]() Note: See http://www.gs1.org/standards for more information.

Note: See http://www.gs1.org/standards for more information.

![]() Note: Not depicted in the diagram is the GS1 Global Product Classification (GPC) standard. GPC codes are static codes that are used to group similar products. The GPC can be used to aggregate data across suppliers, for example to show the origin of a certain type of crop by country. For more information see http://www.gs1.org/gpc .

Note: Not depicted in the diagram is the GS1 Global Product Classification (GPC) standard. GPC codes are static codes that are used to group similar products. The GPC can be used to aggregate data across suppliers, for example to show the origin of a certain type of crop by country. For more information see http://www.gs1.org/gpc .

Framework for interoperable traceability systems

This document provides a framework for the creation of interoperable traceability systems based on the GS1 system of standards. It defines the minimum elements that are needed to achieve interoperable traceability systems, and describes how additional elements can be added to address requirements of specific sectors, product categories, regions and application areas.

Figure 2‑7 GTS framework for interoperable traceability systems

At the foundation, the core of the framework is designed to cover the base requirements of all sectors, regions, applications and trading partners.

The core can be extended to include sectorial and regional layers that are designed to address specific requirements, for example regulatory requirements.

On top of that, the system can be further tailored to address requirements based on supply chain partner relationships and agreements that may need to be considered.

![]() Important: Whenever possible, user-specific (non-standard) extensions should be avoided, since they will add complexity and cost for other parties in the supply chain and reduce interoperability.

Important: Whenever possible, user-specific (non-standard) extensions should be avoided, since they will add complexity and cost for other parties in the supply chain and reduce interoperability.

Besides fully GS1-based implementations, the GTS framework also supports hybrid implementation, where GS1 standards are combined with non-GS1 standards (e.g., ISO) or legacy solutions. Some examples:

■ Animal identification (a regulator assigned ID may be mandatory)

■ Intermodal container identification (the BIC code, covered by an ISO standard, is formally approved for use in the GS1 EPCIS standard)

The conditions and rules under which non-GS1 standards may be applied will need to be precisely defined, in order to prevent duplicate solutions for the same business need.

Finally, the GTS framework provides a path for organisations to increase the interoperability of their traceability system. Industry sectors may, for example, be progressing towards adoption of certain identifiers (i.e. GLNs) and data sharing standards, but may not yet have reached 100% adoption.

3 Traceability data and traceability systems

3.1 Traceability data within an organisation

3.2 Traceability data across supply chains

3.3 Managing traceability data

3.4 Traceability systems

3.5 Traceability systems in action: An example

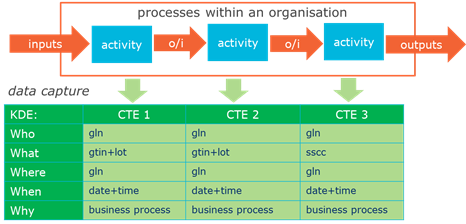

When it comes to traceability data, an organisation should first look at its internal business processes. The organisation should identify which steps in those business processes are important from a traceability perspective. Subsequently, the organisation will need to establish processes to define and capture all of the relevant data about these business process steps, which will enable the effective use of the data within and outside of the organisation.

Business processes will extend across a variety of departments of the organisation, and therefore a common language is critical to implementations of data capture solutions. At the core of this are two concepts:

■ Critical Tracking Events (CTEs)

These are the actual events that occur to the traceable objects during their lifecycle, such as receiving, transforming, packing, shipping, transporting.

■ Key Data Elements (KDEs)

These are the pieces of data that describe the actual instances of the CTEs. The data will commonly cover the five dimensions (Who, What, Where, When, Why) described in section 2.3 .

Figure 3‑1 Critical Tracking Events (CTE) and Key Data Elements (KDE) - example

End-to-end supply chain traceability extends the responsibilities of the organisation to include the exchange of data outside of the walls of any one enterprise (see section 3.2 ).

Each member of the supply chain should, at a minimum, be able to trace back to the direct suppliers of traceable objects and to track forward to the direct recipients of traceable objects (in some cases even including end-consumers). This enables the possibility for all parties to gain access to relevant data further upstream and downstream through queries of direct trading partners (often referred to as a “one-up, one-down” approach, described in more detail in section 3.3.5 ).

Although each party will have its own traceability system, these solutions will need to understand each other and be able to exchange data with each other. This is even true in cases of shared traceability systems (such as vertically integrated retail operations). The design of each individual system will be based on the traceability responsibilities of each party in the end-to-end supply chain, and may be influenced by outside forces such as regulation.

End-to-end traceability refers to the ability to track and trace an object through its entire life cycle and through all parties involved in its production, custody, trade, transformation, use, maintenance, recycling or destruction. Traceability requirements may extend from all the way upstream (suppliers of raw materials, ingredients and components) to all the way downstream (customers of finished goods including end-consumers).

Figure 3‑2 Traceability data across supply chains

Because of the complexities inherent to most supply chains, each party will need to ensure traceability data can flow in two directions (upstream and downstream). Systems will need to support parties querying for data that may exist upstream or downstream from the organisation. As explained in section 2 , standards for the identification, capture and sharing, are a key enabler in achieving the required interoperability to establish connections between the systems of the different parties.

Emergent supply chains

A significant challenge for traceability systems is that, for most products, the chain of custody and chain of ownership are not defined in advance. Instead, they are usually chains or paths through a supply chain network that emerge over time, during the course of normal supply chain operations. We call these supply chains “emergent”.

For example, instances of a product that are manufactured and shipped together may ultimately reach different destinations, and the manufacturer or brand owner will typically have no knowledge of the routes taken by the individual instances of the product. Similarly, upstream, a party often does not know the identity of the suppliers of its suppliers (tier 2 suppliers and beyond). Such relationships may represent sensitive commercial information, and the further upstream one goes (tier 3, 4, 5 etc.), the less visibility there may be regarding the parties that were involved.

Because of these complexities, it is essential to be able to understand, through some means of discovery, which parties were participants in a supply chain activity and who may have relevant traceability data. Furthermore, when parties do not have a direct business relationship with one another, some means of establishing trust is critical, as commercially sensitive data may be included or derived.

See section 4.3.3 Data discovery, trust and access control for more information.

Traceability data originates from a variety of functions and processes within companies, including design and quality control data for the product; production process data; procurement data and logistics and distribution data. Several departments may need to be involved and several internal systems may need to play a role. Some of the data can be commercially sensitive and may require special processing or partial redaction before being made available to third parties.

Some data will be more stable over time (e.g., master data) and can be communicated in advance of receipt of traceable objects. Other data will be added whenever relevant critical tracking events or transactions occur.

The volume of traceability data that is collected over time can be quite significant, creating challenges in terms of time and cost to collect, store and provide access to the data. Preparation for data retention should be considered to manage these challenges.

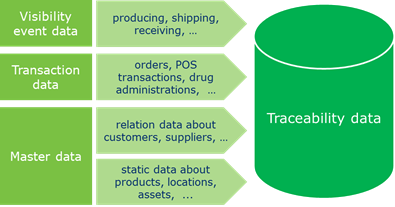

3.3.1 Sources of traceability data

There are four sources of data that contribute to what we define as “traceability data”. These four data sources may be managed in different systems of an organisation, but together they provide the information that is critical in understanding the full context of traceability data.

■ Master data: Master data are the single source of common business data used across all systems, applications, and processes for an entire organisation.

□ Static master data (referred to as “static data” throughout this document) typically exists to describe products, parties, locations, and assets.

□ Master data about supply chain relations (referred to as “relation data” throughout this document) typically exist to describe the supply chain partners of an organisation (i.e. its suppliers and customers), specified by product category and location. When relation data are linked across organisations, this enables the creation of a complete map of the supply chain (upstream and downstream). And, when relation data are enhanced with qualitative data such as certifications, this helps organisations to gain insight in environmental, ethical and safety aspects of the supply chain.

■ Transaction data: Transaction data are recorded as a result of business transactions, such as the completion of a transfer of ownership (e.g. orders, invoices) or a transfer of custody (e.g. transport instruction, proof-of-delivery). Transaction data may be recorded with the aid of electronic data exchange (EDI) and AIDC techniques (e.g., POS scanning, bedside scanning).

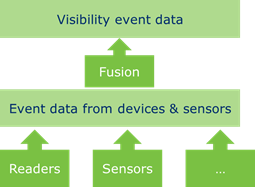

■ Visibility event data: Visibility event data are records of the completion of business process steps in which physical or digital entities are handled. Each visibility event captures what objects participated in the process, when the process took place, where the objects were and will be afterwards, and why (that is, what was the business context in which the process took place). Unlike the other types of data, visibility event data are often specifically recorded for visibility and traceability purposes. Visibility event data will often be captured using AIDC techniques such as barcodes or RFID.

Figure 3‑3 Sources of traceability data

3.3.2 Precision of traceability data

The precision of traceability data is determined by two main dimensions:

1. The level of identification of the traceable objects (products and resources),

2. The granularity at which traceability data is recorded.

Together these two dimensions provide organisations a way to establish the optimal level of precision.

As illustrated in figure 3-4 the combinations with the lowest precision help to provide transparency, which is a basis for traceability. The combinations with the highest precision help to provide traceability, enabling organisations to locate specific traceable objects in a supply chain.

Visibility event data recorded at serial level provide the highest fidelity in the sense that:

1. Visibility event data record the completion of each business process step, including 'internal' processing steps that do not directly refer to specific transactions between trading parties.

2. A serialised object can only exist in one place at any point in time, so it makes a single unambiguous path through the supply chain network.

Figure 3‑4 Precision of traceability data

The following example illustrates how these combinations apply to trade items:

■ Trade items may be identified at class-level (GTIN), lot-level (GTIN + batch/lot ID) or instance-level (GTIN + serial ID).

■ Data may be available about the relations, transactions and visibility events that involve the trade item.

This leads to the following possible levels of precision in the available traceability data:

Table 3‑1 Precision of traceability data for trade items

| Detail of identification | Master data about relations | Transaction data | Visibility event data |

| GTIN | The suppliers / customers per trade item. | The suppliers / customers and related transactions (such as orders and invoices) per trade item. | The suppliers / customers and related events (such as manufacturing, picking, packing, shipping) per trade item. |

| GTIN + batch/lot ID |

| Same as above, but specified at batch/lot-level. | Same as above, but specified at batch/lot-level. |

| GTIN + serial ID |

| Same as above, but specified at serial-level. | Same as above, but specified at serial-level. |

3.3.3 Sensitivity of traceability data

An important aspect to consider is the potential sensitivity of the traceability data that an organisation may choose to share with other parties.

Generally, a distinction can be made between internal data —data not suitable for sharing with other parties, for example due to commercial or privacy reasons— and external data —data suitable for sharing with other parties if certain pre-defined conditions are met—. See Table 3‑2 for examples of data that may be treated as internal vs external by an organisation.

![]() Note: The organisation will also need to consider access restrictions to any internal data that may be shared across organisational lines. Internal access restrictions vary widely across industries and regions.

Note: The organisation will also need to consider access restrictions to any internal data that may be shared across organisational lines. Internal access restrictions vary widely across industries and regions.

Table 3‑2 Example of internal vs external data of an organisation

| Sensitivity of data | Master data | Transactional data | Visibility event data | |

| External data | Static data: ¡ Locations ¡ Catalogue items ¡ Assets ¡ … | Relation data: ¡ Suppliers ¡ Customers ¡ 3rd party service providers ¡ … | ¡ Purchase orders ¡ Despatch notifications ¡ Transport instructions ¡ … | ¡ Producing ¡ Picking ¡ Packing ¡ Shipping ¡ Receiving ¡ … |

| Internal data | ¡ Product design ¡ Production process ¡ Personnel ¡ … | ¡ Contracts ¡ … | ¡ Quality inspection data ¡ Lab analysis results ¡ .. | ¡ Inspecting ¡ Collecting ¡ Holding ¡ … |

As such, this standard focuses mainly on the sharing of external traceability data.

3.3.4 Quality of traceability data

The quality of data provided by each trading partner is critical because inaccurate data which is shared between trading partners could affect other business processes like a trace request or recall activity.

Establishing and maintaining a good quality level of traceability data is a major challenge. Some important aspects are:

■ Completeness: Are all relevant data recorded?

■ Accuracy: Are the recorded data accurately reflecting what happened?

■ Consistency: Are the data aligned across systems

■ Validity: Are the data time-stamped, to ensure the validity timeframe of data is clear?

3.3.5 Sharing of traceability data

When it comes to providing access to traceability data to supply chain partners or other stakeholders, five main models (traceability choreographies) can be distinguished. They result from the different ways in which traceability data can be systematically stored and made available to other parties.

The following example illustrates how the five different traceability choreographies compare, based on a simple scenario that involves three different organisations:

Figure 3‑5 Traceability choreographies

![]()

In the one step up-one step down model the parties keep the traceability data in their own local system. Information requests are exchanged between immediate trading partners upstream or downstream. This model enables traceability data to be exchanged and partially checked between each pair of trading partners, and further upstream or downstream one step at a time.

![]()

In the centralised model the parties share the traceability data in a central repository and send their information requests to it.

Note that some centralised repositories (e.g. those operated by a regulatory authority) may only provide a capture interface but might not make the query interface available to all contributing parties, instead preferring to limit query access to the owner of the repository. Other centralised repositories may support different access control policies, providing query access to all parties – or based on supply chain role – or whether the querying party can prove that they are on the chain of custody / ownership / transactions for the objects specified in their query.

In the networked model the parties keep the traceability data in their own local system and stage it in a way that enables all supply chain partners (not only immediate trading partners) to query the data.

Networked models may differ according to the access control permissions about who is allowed to retrieve the data. In some models, any member of the community or network of supply chain partners may be entitled to query and retrieve data. In other models, access may depend on supply chain role, e.g. to prevent one manufacturer from querying a rival manufacturer’s data; or access may depend on whether the querying party can prove that they are on the actual chain of custody / ownership / transactions for the objects specified in their query.

The cumulative scenario is a push method where the traceability data is systematically enhanced and pushed forward to the next party in the chain in parallel of the product flow. It enables sharing of upstream data with parties further downstream, but not the opposite.

This approach results in highly asymmetric visibility across the supply chain, in which downstream parties receive a complete copy of all relevant upstream data, while the upstream parties have no visibility downstream beyond their immediate 1-down customer. This approach can also be quite challenging for downstream parties to receive and process large volumes of traceability data, especially if the processing involves checking of multiple nested digital signatures.

The fully decentralised and replicated scenario is a mix of the cumulative scenario and networked scenario, and typical for the blockchain technology. The traceability data is systematically enhanced and all supply chain partners involved in the network keep a local copy of all data.

See section 4.3 for more information on the way the GS1 data sharing standards relate to the traceability choreographies.

When we use the term “traceability system”, we are referring to the set of methods, procedures and routines used by an individual party to manage traceability in its supply chains.

Traceability systems are used by individual parties to increase visibility across their own organisation and then to share that visibility data with upstream and downstream parties to contribute to end-to-end supply chain traceability.

Each organisation bases its traceability system on a careful balance between costs, benefits and risks. They will need to do so by taking their role in the wider supply chain context into account, since the needs of direct customers and end-customers will be an important consideration.

All traceability systems should be designed to mitigate risk and, as a by-product, enable visibility of the product’s life cycle.

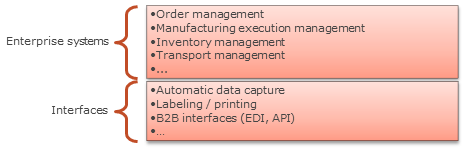

Components

A complete traceability system will include components that manage:

1. Identification, marking and attribution of traceable objects, parties and locations.

2. Automatic capture (through a scan or read) of the movements or events involving an object.

3. Recording and sharing of the traceability data, either internally or with parties in a supply chain, so that visibility to what has occurred may be realised.

Depending on the size of the organisation, multiple IT components may be involved, and the organisation will need to embed the traceability capability into these components.

Figure 3‑6 Traceability capability in IT system components

Interoperability is an important factor in ensuring the seamless interplay between the various system components of an organisation.

Scope

The scope of the traceability system of a party will depend on the role of the party and the traceability questions that need to be addressed. Some elements that define the scope of a traceability system are:

■ How many tiers up and down your supply chains will you need to share data?

■ Will you need to interact with only direct supply chain partners, or will your system require a broader scope?

■ Will you track main ingredients only, or also packaging and indirect materials?

■ Will your system need to integrate data sharing with final consumers / end customers?

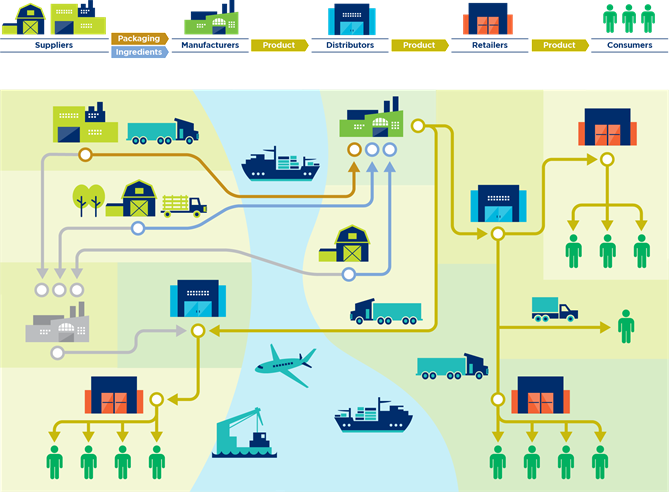

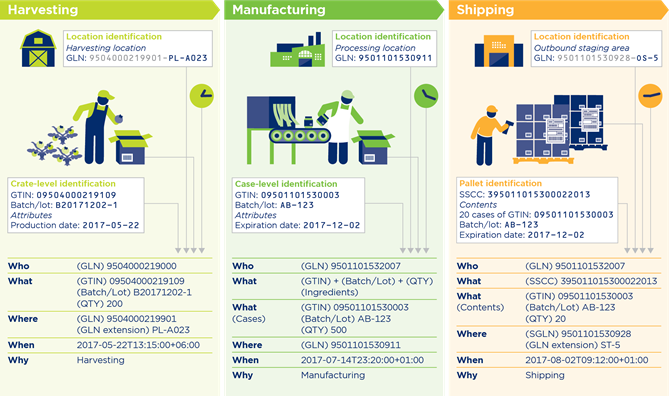

In this section a generic example is given that illustrates the functions of a standards based traceability system. In the example, globally unique identifiers are used for the trade items, logistic units, parties and locations. Automatic data capture techniques such as barcodes are used across the supply chain to gather the traceability data based on the activities in the supply chain.

![]() Note: See appendix D for sector-specific traceability examples

Note: See appendix D for sector-specific traceability examples

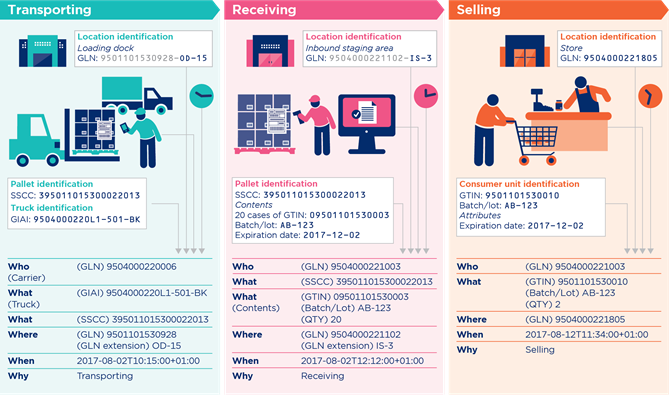

Figure 3-7 provides an overview of the supply chain. It illustrates how ingredients and packaging are supplied, transformed into products and distributed to the final customers.

Figure 3‑7 Supply chain overview

On the next pages, figures 3-8 and figure 3-9 illustrate some of the business process steps that will occur at various points in the supply chain. Each step will lead to one or more critical tracking event (CTEs) for which key data elements (KDEs) need to be recorded.

Figure 3‑8 Traceability data collection in business process steps (1)

Harvesting:

The producer harvests the crop and packs the products into in cases. Each of the cases gets a label with GTIN + batch/lot ID, and the related data are recorded.

Manufacturing:

The manufacturer transforms ingredients into final products. After that, the manufacturer packs the products into cases.

To maintain traceability the inputs and outputs of the process are recorded on batch/lot level.

Shipping:

The warehouse department picks the goods and packs them onto pallets.

To maintain traceability the warehouse records the links between product IDs (GTIN + batch/lot ID) and pallet IDs (SSCC).

Subsequently, the pallets are moved to the outbound staging area to be collected by the carrier.

Figure 3‑9 Traceability data collection in business process steps (2)

Transporting:

The carrier arrives and loads the pallets onto the truck. The driver uses his mobile device to identify each of the pallets. The link between the pallets and the truck is recorded. Now, by tracking the truck also the pallets and goods can be tracked.

Receiving:

The pallets arrive in the retail distribution centre.

The incoming goods department inspects the received goods by scanning the SSCCs on the pallet label and comparing the data against the pre-registered information in the system.

When all checks are ok, the goods will be marked as available in the inventory management system.

Selling:

The products have arrived at the store and have been placed on the shelves.

A consumer has decided to buy two products. At the checkout, the clerk scans the barcode on the products. The system automatically checks the expiry date.

The sales are recorded, in addition to the GTIN also the batch/lot ID is registered.

On this page, two examples are included that illustrate the way traceability data can be applied.

In the first example, figure 3-10, a retailer needs to find upstream information about the origin of a particular ingredient, which growers were involved and the quality certificates they have. By following the chain of custody upstream, the grower is located, and the required information is retrieved.

Figure 3‑10 Data usage: Upstream query

In the second example in figure 3-11, a manufacturer needs to locate products of a specific batch/lot that need to be recalled from the distribution network. By following the chain of custody downstream all points in the distribution network where instances of the batch/lot were observed are identified, enabling a targeted recall.

Figure 3‑11 Data usage: Downstream query

4 Key enablers for interoperable traceability systems

Traceability is a multi-party, multi-chain challenge. Therefore, alignment and collaboration with supply chain partners is essential. This is where standards come into play. Open supply chain standards enable interoperability between all parties by establishing a common set of rules for identification, data capture, data sharing and data usage.

The GS1 system is an integrated suite of global standards that provides supply chain visibility through the accurate identification, capturing, and sharing of information regarding products, parties, locations, assets, and services.

Using GS1 identification keys, companies and organisations around the world are able to globally and uniquely identify physical things like trade items, physical locations, assets, and logistic units as well as intangible things like corporations or a service relationship between distributor and operator. When this powerful identification system is combined with data capture and data sharing methods, connections can be made between these physical or logical things and the information that organisations across the supply chain need about them.

In summary, organisations can identify products and locations using a standardised product identification and standardised location identification method. Additionally, companies can capture the standardised identification in a common approach – barcodes and/or EPC/RFID tags. Finally, once companies are using a common language to identify and capture product data, the information can be shared in a standardised format, ensuring data completeness and accuracy.

4.1 Identification of objects, parties and locations

4.2 Automatic identification and data capture (AIDC)

4.3 Sharing traceability data

4.4 The traceability solution ecosystem

4.1.1 Traceable objects

A traceable object is a physical or digital object whose supply chain path can and needs to be determined. The table below lists the GS1 keys that are available for the identification of traceable objects.

Table 4‑1 GS1 identification keys for traceable objects

| Key | Full name | Type of objects being identified |

| GTIN | Global Trade Item Number | Types of products at any packaging level, e.g., consumer unit, inner pack, case, pallet. |

| SSCC | Serial Shipping Container Code | Logistic units, combination of trade items packaged together for storage and/or transport purposes; for example a case, pallet or parcel. |

| GSIN | Global Shipment Identification Number | Grouping of logistic units that need to be delivered together. Typically used by shippers to instruct transport providers or freight forwarders. |

| GINC | Global Identification Number for Consignment | Grouping of logistic units (that may belong to different shipments) that need to be transported together. Typically used by freight forwarders to instruct transport providers; for example, on a Master Airway Bill (MAWB) or a Master Bill of Lading (MBL). |

| GIAI | Global Individual Asset Identifier | Assets such as vehicles, transport equipment, warehouse equipment, spare parts. |

| GRAI | Global Returnable Asset Identifier | Returnable transport items such as pallets, crates, beer kegs, roll cages. |

| GDTI | Global Document Type Identifier | Physical documents such as invoices, tax forms, etc. |

| CPID | Component / Part Identifier | Components / parts that are produced and identified based on specifications of an Original Equipment Manufacturer (OEM), for example a car manufacturer. |

| GCN | Global Coupon Number | Paper and digital coupons. |

| Notes: ¡ GTIN and CPID only include a type reference, making these keys suitable for class-level identification. Only in combination with other attributes are they suitable for batch/lot-level or serial-level identification. ¡ GRAI, GDTI and GCN include a type reference and an optional serial component, which makes these keys suitable for class-level as well as instance-level identification. ¡ SSCC and GIAI only include a serial reference, and are instance-level identifiers. ¡ GINC and GSIN include a consignment or shipment reference and are used to identify groupings of logistic units. | ||

Trade item identification

The GS1 system provides globally unambiguous identification keys to provide a common language for the communication of product information from company to company. The GS1 identification key for products is the GS1 Global Trade Item Number (GTIN). For decades, this GS1 identification key has facilitated the sharing and communication of product information among supply chain partners. Moreover, it has provided the foundation for innovative improvements in supply chain management for many industries.

GS1 standards provide a choice regarding the granularity of trade item identification, leading to varying degrees of precision as it pertains to traceability that can be achieved, as summarized in the following table.

Table 4‑2 Trade item identification - precision levels

| Granularity | GS1 identification key | Comments |

| Class-level | GTIN | All products of a given type (e.g., 10 count cases of jars of jam) are marked identically. It is possible for an information system to tell one product from another (e.g., a 10 count case from a 24 count case), but not to distinguish two of the same product type (two separate 10 count cases of jars of jam). This is typically the least expensive kind of marking because the marking can be incorporated into package artwork that is printed in bulk. |

| Batch/Lot-level | GTIN + batch/lot number | All product of a given type (e.g., 10 count cases of jars of jam) within a given batch/lot are marked identically. It is possible for an information system to tell one product from another (e.g., a 10 count case of from a 24 count case), and to distinguish two products of the same type from different lots/batches (a 10 count case of jars of jam from Lot #20100201 and a 10 count case of jars of jam from Lot #20100204), but not to distinguish two products of the same type within the same batch/lot. |

| Instance-level (full serialisation) | GTIN + serial number (a combination also known as Serialised GTIN or SGTIN) | Each specific occurrence of a given product (e.g., a specific 10 count case of jars of jam) is marked with a unique serial number, and so the combination of GTIN + serial number is a globally unique identifier for a single product instance, different from all other physical objects in the world. |

Reading from top to bottom, each choice gives increased ability to trace products in the supply chain, though at the cost of increased bookkeeping and cost of product marking.

Class-level identification (GTIN) provides the ability to see where different products are used in the supply chain, and to gather data based on counting products. This includes many inventory applications, sales analysis, etc. However, at this level, all instances of a given product are indistinguishable, which prevents real traceability.

Batch/lot-level identification (GTIN + batch/lot ID) provides the ability to distinguish products in one batch/lot from another batch/lot. This is especially useful in business processes that deal with quality issues that tend to occur on a batch-by-batch basis, such as a product recall of a contaminated batch/lot. Batch/lot-level traceability lets you identify all the places in the supply chain where a given batch/lot has reached, and confirm the quantity of items present from that batch/lot.

Instance-level, or fully serialised identification (GTIN + serial ID) provides the ability to identify each product instance individually. This allows each product instance to be tracked or traced individually, and therefore to precisely correlate observations at different times in the supply chain. This is for example useful for products with a long product lifecycle, where traceability requirements extend to business processes related to the use and maintenance of the product.

Instance-level identification has the unique advantage that the identifier represents one individual instance that can only exist in one location at a particular point in time. The other identification levels allow multiple instances or quantities (fixed or variable measure) with the same identifier to exist in multiple locations at a particular point in time, which limits the amount of knowledge about the instance(s). For example, the specific chain of custody of an object can be evaluated precisely if instance-level identifiers are used – but otherwise can only be estimated in a probabilistic manner.

![]() Note: Supply chain and logistics systems will often only support batch/lot-level traceability, since they are designed to concurrently handle a wide range of products. This means that even when each final product instance is assigned a serialised identifier during manufacturing, it may be advisable to also include a batch/lot identifier, both on the product as well as on the outer packaging.

Note: Supply chain and logistics systems will often only support batch/lot-level traceability, since they are designed to concurrently handle a wide range of products. This means that even when each final product instance is assigned a serialised identifier during manufacturing, it may be advisable to also include a batch/lot identifier, both on the product as well as on the outer packaging.

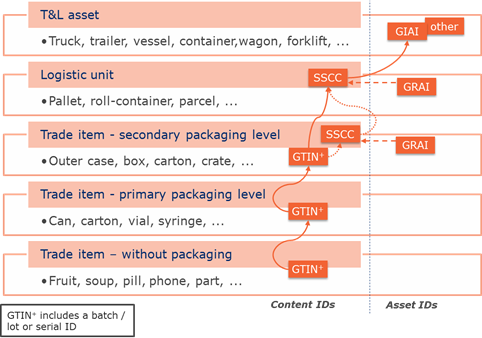

Traceable objects in distribution and logistics

In distribution and logistics, trade items are often aggregated (grouped, packaged, loaded). This leads to other traceable objects needing to be tracked and traced, for example logistic units, containers, trucks and vessels. The diagram below illustrates how these types of objects relate to each other and how the GS1 identification keys can be applied.

Figure 4‑1 Traceable object aggregation levels and identification keys

In order to preserve the relation between the higher aggregation levels and the contained trade items, the links between the various aggregation levels will need to be recorded. This is one of the essential elements of a traceability system, and key for establishing connections between the traceability systems of the various parties (including logistic service providers).

There is a difference in nature between the GTIN and SSCC on the one hand and GIAI and GRAI on the other hand. Whereas SSCC and GTIN identify goods or products including their packaging, the GIAI and GRAI identify the T&L asset independent of its contents. A special situation occurs when assets themselves are being distributed, for example empty pallets. In such cases asset IDs can also be used to identify the contents.

![]() Note: Not depicted in figure 4-1 are the GSIN and GINC. These GS1 identification keys serve to identify groupings of logistic units and are used in combination with an SSCC.

Note: Not depicted in figure 4-1 are the GSIN and GINC. These GS1 identification keys serve to identify groupings of logistic units and are used in combination with an SSCC.

4.1.2 Traceability parties

In any traceability system, it is important to distinguish the various actors who play a role in the chain of custody or ownership of a supply chain. Examples of parties in the supply chain might include a manufacturer, a broker, a distributor, a carrier, or a retailer. In order to understand the full context of traceability, understanding WHO played a role and sometimes their relationship to each other in the chain is essential. Identification of parties can be accomplished with the Global Location Number (GLN). In some cases, especially when identifying individuals involved, the Global Service Relation Number (GSRN) can also play a role.

Table 4‑3 GS1 identification keys for traceability parties

| Key | Full name | Type of supply chain information |

| GLN | Global Location Number | Trading partners (legal entities as well as functional entities such as a department) |

| GSRN | Global Service Relation Number | Service relationships (provider as well as recipient) |

4.1.3 Traceability locations

A traceability location is a designated physical area that has been selected to be in scope of a traceability system.

Physical locations defined by an organisation for their business operations can be identified using the Global Location Number (GLN).

Table 4‑4 GS1 identification keys for physical locations

| Key | Full name | Type of supply chain information |

| GLN | Global Location Number | Locations |

| Global Location Number + GLN extension component | (internal) Locations within a site |

The GLN can be used to identify business locations as defined by a specific party. In traceability systems other locations can also be of importance. For this reason, the GS1 standards support additional ways to identify locations, such as geographic coordinates.

4.1.4 Transactions and documents

In cases where references to documents or transactions need to be shared across parties, globally unique identifiers enable unambiguous identification across systems of parties. For example, globally unique identifiers could be applied to quality certificates assigned by certification bodies.

Table 4‑5 GS1 identification keys for documents and transactions

| Key | Full name | Type of supply chain information |

| GDTI | Global Document Type Identifier | Physical documents such as certificates, driving licenses, and electronic documents such as digital images and EDI messages. |

Traceable objects —and in some cases also parties, locations, transactions and documents— will need to be physically identified to enable traceability.

Traceability systems can use GS1-approved barcode symbologies and EPC/RFID tags to encode GS1 identification keys that uniquely identify products, trade items, logistic units, locations, assets, and service relations worldwide. Additional information such as best-before-dates, serial numbers, and lot numbers may also be encoded into barcodes or EPC/RFID.

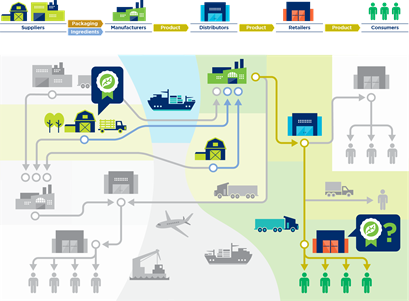

Besides barcodes and EPC/RFID, other carrier-based technologies (such as digital watermarks) and carrier-less technologies (such as image recognition) may also play a role.

In addition to the data that is captured from objects, data provided by the equipment used to scan or read the data —such as date & time, read-point and user (operator)— will be important in determining the who, where, when and why dimensions.

Figure 4‑2 Data capture technologies and the 5 dimensions

4.2.1 Applying data carriers

Barcodes

The marking of traceable objects is driven by the level of identification. Batch/lot-level or serialised identification are dynamic data and therefore cannot be included in the artwork of the packaging. This means that adding dynamic data in a barcode will have an impact on printing and packaging speeds.

Traditionally, barcodes on consumer units were used for POS scanning and only contained the Global Trade Item number (GTIN), also known as EAN or UPC. With evolving product safety regulations and product information requirements, other types of data are making their way to the barcodes on consumer products. Besides the batch/lot ID and/or serial ID these may also include the expiry date, best before date, etc. The proper linkage of the barcode, the related data and the produced instances of the trade item, is a key aspect.

Looking at trade item groupings such as outer cases, traditionally barcodes containing a GTIN were applied, in some cases pre-printed on the case, but also quite often included on a label. In recent years, dynamic data have made their way to case labels causing such barcodes to be increasingly printed inline.

For logistic units the barcodes have always been based on the SSCC, which is a serialised identifier. This means that logistics labels will be printed when the goods are packaged, and that the link between data and label will be secured that way.

Table 4‑6 GS1-barcodes overview

|

| GS1 barcodes that support only a GTIN | GS1 barcodes that support all GS1 identification keys as well as attributes |

| 1D symbols | EAN/UPC, ITF-14, GS1 DataBar (non-expanded) | GS1-128, GS1 DataBar (expanded) |

| 2D symbols |

| GS1 QR Code, GS1 DataMatrix |

![]() Note: Matrix symbols (2D) require image-based scanners. Linear symbols (1D) can be read by laser as well as image-based scanners.

Note: Matrix symbols (2D) require image-based scanners. Linear symbols (1D) can be read by laser as well as image-based scanners.

EPC/RFID

EPC/RFID tags are by definition serialised. A special aspect is that EPC/RFID tags will often be pre-written, requiring the link between the issued serialised identifier and the associated data to be recorded afterwards.

Example

The example below illustrates the entities that need to be automatically identified in the healthcare sector, and which carrier techniques are applied.

Figure 4‑3 Example of GS1 barcodes and EPC/RFID tags as applied in healthcare

4.2.2 Capturing data

When it comes to capturing the data, the main questions are:

1. Which process steps need to be captured?

2. What is the most cost effective way to capture the data?

Usually the first step will be scanning of logistic units upon receipt. For barcodes this is often done using handheld devices. For EPC/RFID tags, fixed readers can be used. Other process steps where data will be captured are storing, picking, packing, shipping, transporting, selling. Often a combination of fixed mounted scanners or readers and hand held devices will be applied to capture the critical tracking events.

The emergence of mobile devices deserves a special mention here, since it increases the availability of scanning capability (making scanning as pervasive as the barcode) and so may make it feasible to record additional events at limited additional cost.

The collection of traceability data from other parties and the provision of data to other parties are essential components in distributed traceability systems. The five traceability choreographies (see section 3.3.5 ) all pose different requirements when it comes to the standards-based exchange of data.

4.3.1 Separation of content and communication method

An important principle is the separation of data content from the way the data is exchanged (the communication method).

In terms of data content, GS1 standards for business data pertain to three categories of business data that are shared between end users:

■ Master data that provide descriptive attributes of real-world entities identified by GS1 identification keys, including trade items, parties, and physical locations.

■ Transaction data that consist of trade transactions, triggering or confirming the execution of a function within a business process as defined by an explicit business agreement (e.g., a supply contract) or an implicit one (e.g., customs processing), from the start of the business process (e.g., ordering the product) to the end of it (e.g., final settlement), also making use of GS1 identification keys.

■ Visibility event data provide details about activity in the supply chain of products and other physical or digital assets, identified by keys, detailing where these objects are in time, and why; not just within one company’s four walls, but throughout the supply chain. It makes it possible to track and trace goods with live data along the process.

The communication methods applied in the GS1 standards may be broadly classified in two groups:

■ Push methods, where one party unilaterally transfers data to another in the absence of a prior request. Push methods may be further classified as:

□ Bilateral party-to-party push, where one party transfers data directly to another party.

□ Publish/subscribe, where one party transfers data to a data pool or repository, which in turn pushes the data to other parties who have previously expressed interest in that data by registering a subscription (“selective push”).

□ Broadcast, where a party publishes business data in a well-known or publicly-accessible place such as a World Wide Web page, where it may be retrieved by any interested party.

Broadcast does not necessarily mean that the data is available to anyone; the data may be encrypted for a specific intended user or the broadcast channel (e.g. website) may require the receiving party to authenticate and may only grant access to the broadcast data according to specific access control policies.

■ Pull or query methods, where one party makes a request for specific data to another party, who in turn responds with the desired data. Note that in the above classification of Push methods, the Broadcast method may also involve a Pull query, in order to retrieve the data from a publicly-accessible place (such as a website).

See the GS1 System Architecture document [ARCH] for more information.

4.3.2 GS1 data sharing standards and services

GS1 offers several standards and services, based on the types of data and communication methods described above. All GS1 data exchange standards and services are based on the use of GS1 identification keys, rather than relying on internal identifiers or descriptive elements. The use of globally unique keys greatly simplifies implementations between trading partners, since they provide interoperability across the various systems.

Table 4‑7 Overview of GS1 data sharing standards

| Standard | Description | Communication method |

| Master data | ||

| GS1 Global Data Synchronisation Network® (GDSN) | The GS1 Global Data Synchronisation Network® (GDSN) enables trading partners to automatically share their business data with each other. This means organisations can have confidence that when one of their suppliers updates their database, their own database is similarly updated as a result. Everyone has access to the same continuously refreshed data. | Publish / subscribe |

| GS1 Source | GS1 Source is a network of data aggregators who have all agreed to use GS1 standards. Data aggregators gather product data from brand owners and manufacturers, share it with each other on the cloud, and make it available to developers for their web and mobile applications. | Pull |

| GS1 SmartSearch | GS1 SmartSearch standard makes it possible to create structured data about objects and relate this data to its GS1 identification key. The structured data about the object (e.g. a product) can then be used by search engines, smartphone apps, etc. to deliver a richer experience to the user. | Broadcast |

| GLN Service | The GS1 GLN Service provides a single point of access to GS1 GLN master data via an interconnected network of local registries. | Pull |

| GS1 EDI | GS1 EDI provides some messages in support of bilateral master data exchange, in particular the EANCOM PRICAT, PRODAT & PARTIN messages and GS1 XML Item data notification. | Bilateral push |

| EPCIS | There are several ways to transmit master data via EPCIS: (1) Master data query (2) Instance/Lot Master Data (ILMD), (3) Header of EPCIS document (4) EPCIS master data document. See [EPCIS] for more information. | Pull (to support on-demand synchronous queries) as well as Push (publish/subscribe to standing query notifications). |

| Transactional data | ||

| GS1 EDI | GS1 EDI provides trading partners with an efficient business tool for the automatic transmission of commercial data from one computer application directly to another. In EDI, all paper business documents sent previously between companies have been replaced by messages, suitable for exchange by electronic means between computer applications. | Bilateral push |

| Visibility event data | ||

| EPC Information Services (EPCIS) and Core Business Vocabulary (CBV) | The GS1 EPCIS standard enables disparate applications to create and share visibility event data, both within and across enterprises. The GS1 CBV standard specifies the structure of vocabularies and specific values for the vocabulary elements to be used in conjunction with the GS1 EPCIS standard. | Pull (to support on-demand synchronous queries) as well as Push (publish/subscribe to standing query notifications). |

4.3.3 Data discovery, trust and access control

The traceability choreographies mentioned in section 3.3.5 all apply to the three types of data content. However, each choreography applies a different mix of communication methods, as illustrated in the table below.

Table 4‑8 Traceability choreography – applicable communication methods

| Traceability choreography | Publishing / Contributing | On-demand selective query (synchronous) | Selective standing query (asynchronous) |

| One step up-one step down | Push data to relevant trading partner (1-up or 1-down) | Pull |

Publish & subscribe (receive pushed notifications matching previous standing query subscription) |

| Centralised | Push data to centralised repository | Pull | |

| Discovery of networked resources (*) | Push referral link to a Discovery Service | Pull | |

| Networked (*) | Push data to own repository | Pull | |

| Cumulative | Push cumulative data to next 1-down party | Not applicable | |

| Decentralised and replicated | Push data to one node for validation then inclusion and replication in decentralised repository or ledger | Not applicable (All parties connected to the decentralised replicated ledger have read access to all data in the ledger, with automatic updating as new data is added to the ledger; each party can index and query their copy of the ledger and extract the data they need. Note that although the data in the decentralised replicated ledger is readable to all, it may not be understandable to all, if some sensitive data has been stored in a hashed or encrypted manner) | |

| (*) The Networked choreography may require an initial discovery phase (to find the relevant networked repositories), followed by direct interaction with each of the repositories. | |||

Access control

All of the choreographies are in principle capable of selectively restricting access to the meaning of the exchanged data on a need-to-know basis, although they differ in the mechanisms used and in the ability to control whether a receiving party shares the data with additional parties:

■ Some of the choreographies involve bilateral communication between an information requesting party (querying party) and an information providing party, which may be the original contributor of the data or a shared repository holding the data. Privacy of such bilateral communications can be assured via mutual authentication, use of secure communication channels and potential encryption of the data payload or messages.

■ Decentralised and replicated choreographies can involve a different approach to selectively restricting access to the meaning of the data. In the case of a blockchain ledger, trust in the ledger is assured if everyone is able to independently inspect the entire ledger including all of its data, in order to be assured that no historic transaction data has been subsequently altered. Although this openness necessarily means that anyone can read all the data in the ledger, it is still possible to hide the meaning of sensitive data either by encrypting such data or by storing a hash value in the ledger. If hash values are stored in a blockchain ledger, the original data is typically stored elsewhere and exchanged by another mechanism, while the hash value recorded in the blockchain ledger effectively archives a ‘tamper-evident seal’ that corresponds to what the data originally looked like.

Data discovery

It is sometimes desirable to share data between parties who have no direct relationship, but who are connected through a chain of custody, chain of ownership, chain of transactions, or some combination of these.

All traceability choreographies (see 3.3.5 ) enable this in one way or another. The "data discovery problem" is applicable when going beyond the one step up-one step down scenario, and specifically in the case of the networked model. It is concerned with how to directly share data between parties that are connected in a chain but do not have a direct relationship.

Elements of the discovery problem include:

■ Chaining: how does Company A find out which other companies are connected to it by a chain (and who therefore may have data of interest)?

■ Trust: if Company A and Company C discover they are connected by a chain, but have no direct relationship, how can they establish the conditions of trust necessary to share data with each other? Are they able to do this in an automated manner, without human intervention by intermediate companies such as Company B?

■ Data transfer: once companies have discovered each other and established trust, how do they accomplish the sharing of data?

GS1 technical standards to address the data discovery and trust aspects are currently being developed but are not yet ready for market. Much good work has been done to develop the concepts of discovery services (including basic data model and functional requirements). See also section 4.4 .

![]() Note: Please contact GS1 for implementation advice on the topic of data discovery, trust and access control. https://www.gs1.org/contact

Note: Please contact GS1 for implementation advice on the topic of data discovery, trust and access control. https://www.gs1.org/contact

4.3.4 Event data from devices & sensors and the Internet of Things (IoT)

The enormous growth of sensors and actuators in physical devices, and the fact that these devices are increasingly connected to the internet (the Internet of Things) leads to a new category of timestamped event data that is much broader than the visibility event data currently handled by the GS1 ALE (Application Level Events) and EPCIS standards.

Sensors passively record changes in the state of the physical world and the objects contained within it, such as a food temperature sensor in a truck recording events outside an acceptable temperature range. Event data from actuators record a history of intentional changes, such as the opening of a valve for a water reservoir or gas pipeline or the locking/unlocking of a door.

GS1 has started to engage in IoT-related standardisation initiatives, in particular when it comes to the use of identifiers, the interpretation (semantics) and fusion (adding business context) of event data from devices and sensors.