Release 1.3, Ratified, Jul 2019

GS1 Logistic Label Guideline

Provides an overview of the normative rules and best practice recommendations based on GS1 Logistic Label implementations around the world.

- 1 Introduction

- 2 Lay-out of the label

- 3 How to identify the logistic unit

- 4 How to include trade item information

- 5 How to include transport and customer information

- 6 Label lay-out rules

- 7 Size of the GS1 Logistic Label

- 8 Label placement

- 9 Implementation considerations

- 10 Practical examples

- 11 References

- A Appendix A - GS1 Logistic Label verification

- B Appendix B - Label, symbol and text sizes

- Contributors & Change Log

Contents

- 4.1 When would I use this?

- 4.2 Trade item identification

- 4.3 Identification of pieces of a trade item

- 4.4 Count of contained trade items

- 4.5 Trade item measures

- 4.6 Trade item dates

- 4.7 Batch / lot number

- 4.8 Serial numbers

- 4.9 Extract of main GS1 Application Identifi...

- 5.1 When would I use this?

- 5.2 Customer (Receiver) name and address

- 5.3 Supplier (Shipper) name and address

- 5.4 Routing code

- 5.5 Ship for location / ultimate consignee

- 5.6 Shipment identification

- 5.7 Consignment identification

- 5.8 Customer's purchase order number

- 5.9 Logistic measures

- 5.10 Handling and processing instructions

- 5.11 Extract of GS1 Application Identifiers ...

- 6.1 Top building block

- 6.2 Middle building block

- 6.3 Bottom building block

- 6.4 Rules related to label segments

- 8.1 Label placement on larger logistic units...

- 8.2 Label placement on smaller logistic unit...

- 8.3 Label placement on stacked pallets

- 9.1 Best practice processes by role

- 9.2 Label implementation scenarios

- 9.3 Shipper / Supplier

- 9.4 Carrier

- 9.5 Receiver / Customer

- 10.1 SSCC-only label

- 10.2 GS1 Logistic Label for homogeneous logi...

- 10.3 GS1 Logistic Label for homogeneous logi...

- 10.4 GS1 Logistic Label for orderable pallet

- 10.5 GS1 Logistic Label for logistic unit th...

- 10.6 GS1 Logistic Label for mixed pallet

- 10.7 GS1 Logistic Label with logistic unit a...

- 10.8 GS1 Logistic Label with supplier, custo...

- 10.9 GS1 Logistic Label with transport infor...

- 10.10 GS1 Logistic Label with transport info...

- 10.11 GS1 Logistic Label for parcel (SSCC-on...

- 10.12 GS1 Logistic Label for parcel (includi...

- 10.13 GS1 Logistic Label for parcel (includi...

- 10.14 GS1 Logistic Label with identification...

1 Introduction

The GS1 System is the most widely used supply chain standards system in the world and comprises the standards, guidelines, solutions and services created in formalised and collaborative processes.

The Transport & Logistics industry involves the movement of goods using multiple transport modes, including road, rail, air and maritime. T&L processes involve a wide variety of parties such as consignor and consignee, freight forwarders and carriers as well as official bodies like customs and port authorities. The often complex logistics flows and the variety of involved parties imply there is a need for easy physical identification of logistic units. GS1 offers a standard to help accomplish this: The GS1 Logistic Label.

![]()

This guideline provides guidance on how to physically identify logistic units using the GS1 Logistic Label. It is based on the GS1 Standards described in the GS1 General Specifications, and on best practices gathered in various implementation projects around the world.

1.1 Acknowledgements

1.2 Scope of the guideline

1.3 Conventions applied in the guideline

These recommendations have been developed in collaboration with GS1 Member Organisations and the Transport & Logistic (T&L) Member Organisation Interest Group working closely with local communities on Transport & Logistic process efficiencies.

Special acknowledgements to GS1 in Europe, GS1 Germany, GS1 UK, GS1 Norway, GS1 Finland, GS1 Netherlands, GS1 Australia and GS1 US for providing their guidelines and deployment materials. These materials have served as a basis for this guideline, and some of their text and examples have been taken over into this guideline.

1.2.1 Labelling logistic units

The main topic of this guideline is the labelling of logistic units. A logistic unit is an item of any composition established for transport and / or storage which needs to be managed throughout the supply chain.

The GS1 Logistic Label allows users to identify logistic units uniquely so that they can be tracked and traced throughout the supply chain. The only mandatory requirement is that each logistic unit must be identified with a unique serial number, the Serial Shipping Container Code (SSCC).

Scanning the SSCC barcode on each logistic unit allows the physical movement of units to be matched with the electronic business messages that refer to them. Using the SSCC to identify individual units provides the opportunity to implement a wide range of applications such as cross docking, shipment routing, and automated receiving. Besides the SSCC other information can be included on the GS1 Logistic Label.

1.2.2 Labelling trade items such as cartons and outer cases

Trade items such as cartons and outer cases will often have a barcode encoding the Global Trade Item Number (GTIN). The barcode may be an ITF-14, EAN/UPC, or when additional item data is needed, a GS1-128 barcode. It is important to note that such labels, when not containing an SSCC, are not considered to be GS1 Logistic Labels. This guideline mainly addresses logistic labelling. However, notes have been included to explain how information may be provided on cartons and outer cases using a GS1-128 barcode. These notes have been marked as follows:

![]() Note: Carton / Outer Case Labels

Note: Carton / Outer Case Labels

1.2.3 Supported AIDC standards

Automatic Identification and Data Capture (AIDC) technology is an important component of the GS1 Logistic Label. GS1 Logistic Labels have always used GS1-128 barcodes, but this version of the guideline introduces the use of supplementary GS1 2D barcodes. The guideline does not provide guidance on the use of EPC/RFID technologies.

1.3.1 References

References to documents, websites etc. are indicated as follows [REFERENCE, paragraph number (optional)]. The list of references with full details is included in section 11.

1.3.2 Rules and recommendations

To highlight important points, rules and recommendations are numbered within each section. For example, clause [2-3] is the 3rd clause in section 2. Clauses that are marked as 'normative' are rules that are included in the GS1 General Specifications, and these must be adhered to in order to be compliant with GS1 standards. Clauses that are not marked as 'normative' are best practice recommendations.

1.3.3 Format of data elements

The following conventions are applied to indicate the format of GS1 Application Identifiers and data elements.

To indicate the allowed characters:

■ N numeric digit

■ X any character, see [GENSPECS, figure 7.11 - 1] for the allowed characters.

To indicate the length:

■ Nn exact number of digits

■ N..n maximum number of digits

■ Xn exact number of characters

■ X..n maximum number of characters

Examples:

■ X3 exactly 3 characters

■ N..18 up to 18 numeric digits

To indicate digit / character position:

■ Xn

■ Nn

Examples:

■ N3 numeric digit on position 3

■ X16 any character on position 16

2 Lay-out of the label

2.1 Introduction

2.2 Building blocks

2.3 Segments

The information included on a GS1 Logistic Label comes in two basic forms.

1. Information to be used by people: This comprises Human Readable Interpretation (HRI) of the data encoded in the barcodes, and non-HRI text and graphics.

2. Information designed for data capture by a machine: Barcodes.

Barcodes are machine readable and are a secure and efficient method for conveying structured data, while HRI, Non-HRI text and graphics allow people general access to basic information at any point in the supply chain. Both methods add value to GS1 Logistic Labels, and often co-exist on the same label.

![]() Note: HRI and Non-HRI Text.

Note: HRI and Non-HRI Text.

For the purposes of interpreting this guideline, there are two types of text that appear on a label:

1. HRI is the data encoded in the barcode.

2. Non-HRI text is all other text on a label.

The SSCC is the single mandatory element for all GS1 Logistic Labels. Other information, when needed, shall comply with the specifications in this document and with the proper use of GS1 Application Identifiers.

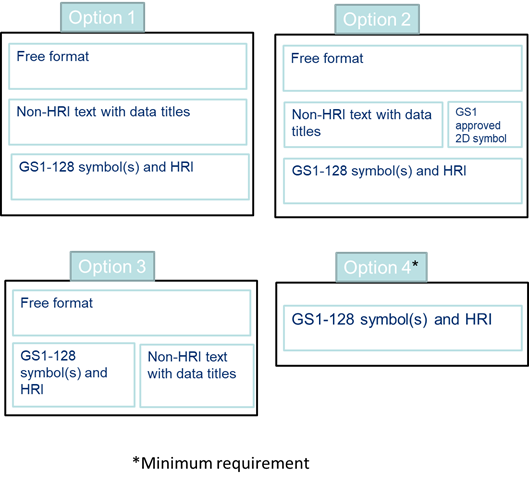

A distinction is made between the types of data communicated on the Logistic label. This is expressed in three building blocks:

1. The top building block may contain anything, e.g. text and graphics. This may include extra information about the logistic unit that is not encoded in the barcode(s).

2. The middle building block contains non-HRI text reflecting the information represented in the barcode(s) using data titles rather than AIs, and optionally additional information not represented in barcodes (preferably including data titles).

3. The bottom building block contains the barcode(s) including human readable interpretation (HRI).

Only the bottom building block is mandatory.

A GS1 2D symbol, if used, should be placed to the right of the non-HRI text including data titles within the middle building block.

If there is enough space, the lower two building blocks may be placed side by side. See Figure below.

Figure 2‑1 Placement of Building Blocks

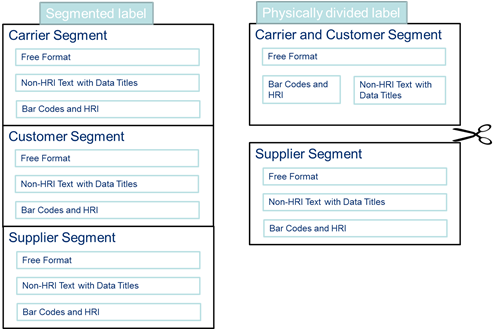

The information to be included on the label may become available at separate stages. Some information may also need to be replaced during the lifetime of the logistic unit. Dividing the label into separate segments is a way to address this.

A segment is a logical grouping of information that is generally known at a particular time. There may be up to three label segments on a GS1 Logistic Label, each representing a group of information. Generally, the order of the segments, from top to bottom, is: carrier (transport), customer, and supplier. However, this order and top/down alignment may vary depending on the size of the logistic unit and the business process being served.

Each segment may contain a combination of the defined building blocks as determined by trading partners.

Segments may be printed as separate labels in which case they must be placed vertically in close proximity to one another, with the segment containing the SSCC at the bottom. When segments are added separately, care should be taken not to obscure existing segments. The carrier segment may be replaced during the journey of the logistic unit, in which case special care should be taken to ensure the customer and supplier segments are preserved.

![]() Important: When adding or replacing a segment an SSCC already present must never be replaced or changed.

Important: When adding or replacing a segment an SSCC already present must never be replaced or changed.

When segments are used, the data within them still needs to be organised using building blocks as described in section 2.2 . In that case segments are the primary grouping mechanism; building blocks are subordinate to that. See figure below for some examples.

Figure 2‑2 Examples of label segmentation

Supplier Segment

The supplier segment of the label contains information that is generally known at the time of packaging by the supplier. The SSCC is applied here as the unit identifier, along with the GTIN if used.

Other information that may be of interest to the supplier but might also be useful for customers and carriers can be applied. This includes product-related information such as product variant; dates such as production, packaging, expiration, and best-before dates; and lot, batch, and serial numbers.

Customer Segment

The customer segment of the label contains information that is generally known at the time of order and order processing by the supplier. Typical information includes the ship to location, purchase order number, and customer-specific routing and handling information. If several logistic units are assembled to be transported under one despatch advice or Bill of Lading (BOL) to one customer the GSIN, AI (402) may also be applied in this customer segment.

Carrier (Transport) Segment

The carrier (transport) segment of the label contains information that is generally known at the time of shipment and is typically related to transport. Typical information includes ship to postal codes, AI (420), Global Identification Number for Consignment, AI (401), and carrier-specific routing and handling information.

3 How to identify the logistic unit

3.1 SSCC

3.2 Including the SSCC on the label

3.3 Extract of GS1 Application Identifiers for logistic unit identification

The format of the SSCC is as follows:

| GS1 Application Identifier | SSCC (Serial Shipping Container Code) | |||

| Extension digit | GS1 Company Prefix | Serial reference | Check digit | |

| 0 0 | N1 | N2 N3 N4 N5 N6 N7 N8 N9 N10 N11 N12 N13 N14 N15 N16 N17 | N18 | |

The Extension Digit can have any value from 0 to 9 and is used to increase the numbering capacity. Its use is at the discretion of the company allocating the SSCC.

The GS1 Company Prefix (GCP) is allocated by GS1 Member Organisations to the company that allocates the SSCC - here the physical builder or the brand owner of the logistic unit. It makes the SSCC unique worldwide but does not identify the origin of the unit. The length of a GS1 Company Prefix depends on each GS1 Member Organisation's policy on number allocation.

The Serial Reference is a serial number created by the company allocating the SSCC. The simplest way to allocate the serial number is sequentially, for example ….00000, …00001, …00002.

The Check Digit is calculated using the algorithm defined by GS1. [GENSPECS, 7.9.1], also see [CHECK] for a calculator.

[3-1] (Normative) The SSCC is the single mandatory element for all logistic labels. [GENSPECS 6.6.3].

[3-2] The SSCC should be assigned by the company that is creating the logistic unit, using its own GS1 Company Prefix.

If the logistic unit is not marked with an SSCC when it is received, the subsequent party in the supply chain may allocate the SSCC. This party can be a logistic service provider or the customer.

4 How to include trade item information

4.1 When would I use this?

4.2 Trade item identification

4.3 Identification of pieces of a trade item

4.4 Count of contained trade items

4.5 Trade item measures

4.6 Trade item dates

4.7 Batch / lot number

4.8 Serial numbers

4.9 Extract of main GS1 Application Identifiers for trade item information

Items that are priced or ordered or invoiced are considered trade items and are identified by a GTIN. Typically, supply chains are most efficient when:

GTIN of ordered item = GTIN on the item being delivered = GTIN of invoiced item.

This is an important consideration in logistic label design.

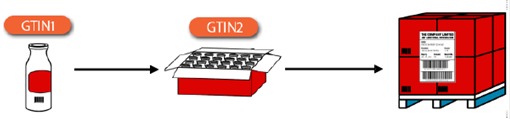

When it comes to including trade item information three types of logistic units can be distinguished:

■ A homogeneous unit containing one type of trade item. All the items at the highest level of packaging are the same and are identified with the same GTIN. Example: a pallet containing 50 trade item groupings of Product X.

■ A heterogeneous logistic unit containing different types of trade items at the highest level of packaging that are identified with different GTINs. Example: a pallet containing 30 standard trade item groupings (e.g. boxes) of Product X and 20 standard trade item groupings (e.g. boxes) of Product Y.

■ A logistic unit that is also a traded unit (one that is priced or ordered or invoiced). Such logistic units can be homogeneous, for example goods in bulk, heterogeneous (for example display units), or a single product (for example a refrigerator, or a mobile phone transported as a parcel).

For homogeneous logistic units and logistic units that are trade items it is possible to include information about the trade item(s) on the logistic label. This can be useful in situations where no despatch advice is used or is unavailable. For heterogeneous logistic units it is not possible to include trade item information on the logistic label and therefore the use of electronic messaging is strongly encouraged to support the exchange of data linked with the SSCC.

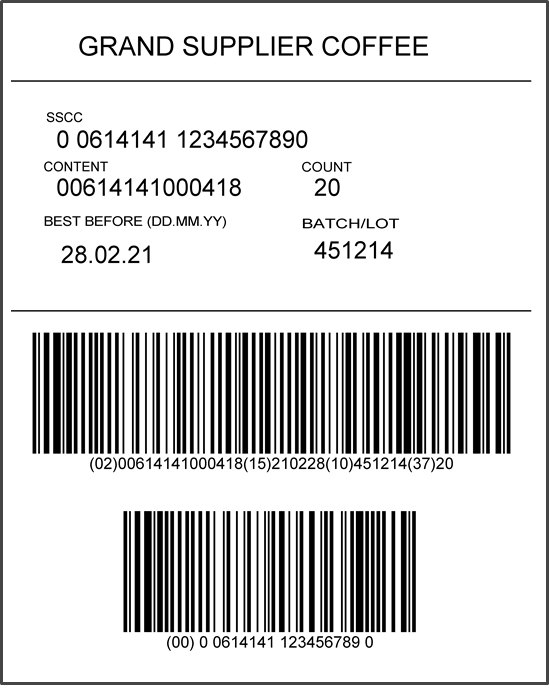

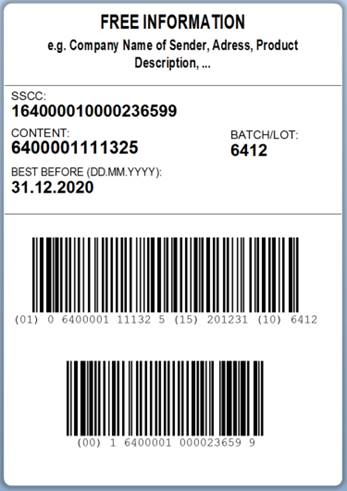

Figure 4‑1 Label including trade item information

|

[4-1] When the logistic unit is homogeneous, and is not a trade item, the contents of the pallet may be defined using AI (02) CONTENT, specifying the GTIN of the included trade items (the highest packaging level contained in the logistic unit).

![]() Note: Use of AI (02) is not the preferred option for regulated healthcare trade items.

Note: Use of AI (02) is not the preferred option for regulated healthcare trade items.

[4-2] When the logistic unit is heterogeneous, and is not a trade item, no GTIN and related trade item information should be included.

[4-3] When the logistic unit is a trade item, the contents of the logistic unit may be defined using AI (01) GTIN, specifying the GTIN of the trade item.

[4-4] (Normative) AI (01) GTIN and AI (02) CONTENT must never be used together on a logistic label. [GENSPECS, 4.14.1]

[4-5] (Normative) AI (02) CONTENT may only be used in combination with AI (00) SSCC and AI (37) COUNT. [GENSPECS, 4.14.2]

[4-6] The trade item description may be included as free text.

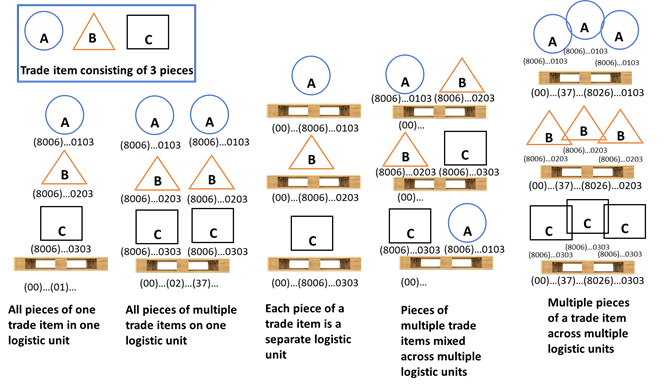

When trade items are too large to be shipped as one logistic unit they will need to be split into separate pieces. This also occurs when some of the pieces have special packaging requirements, e.g. the glass door of a closet.

AI (8006) ITIP can be used for the identification of an individual piece of a trade item. It consists of the GTIN, the piece number (2 digits) and the total number of pieces (2 digits). AI (8006) can be used on the product packaging of the piece as well as on the GS1 Logistic Label.

The following rules address the main scenarios that have been identified:

[4-7] All pieces of a single trade item are delivered together as one logistic unit: AI (01) may be used to identify the trade item.

[4-8] All pieces of multiple trade items are delivered together as one logistic unit: AI (02) and AI (37) may be used to identify the content and their count.

[4-9] Each of the pieces of the trade item is delivered as a separate logistic unit: AI (8006) may be used to identify an individual piece of the trade item.

[4-10] The pieces of multiple trade items are mixed across several logistic units: No trade item or content information shall be included.

[4-11] When several identical pieces of a trade item are transported as one logistic unit, AI (8026) may be used to identify the pieces and their count.

[4-12] (Normative) ITIP of contained pieces may only be used in combination with AI (00) SSCC and AI (37) COUNT. [GENSPECS, 4.14.2-1]

Figure 4‑2 Identification of pieces of a trade item

[4-13] (Normative) When the identification of the contained trade items is provided by using AI (02) CONTENT, the count of trade items contained must be indicated using AI (37) COUNT. [GENSPECS, 4.14.2]

For example, a logistic unit of 12 cases of a product may be described with AI (02) containing the GTIN of the case and AI (37) showing a count of 12 cases.

[4-14] (Normative) The use of AI (37) COUNT is not allowed in combination with AI (01) GTIN. [GENSPECS, 4.14.1]

Trade (net) measures are used to complete the identification of a variable measure trade item. They contain information such as the weight, size, volume or dimension of a variable measure trade item and, therefore, should never be applied alone but with the GTIN (with leading '9').

[4-15] The use of one of the following metric measures is recommended:

□ net weight in kilograms - AI (310n*)

□ length in meters - AI (311n*)

□ area in square meters - AI (314n*)

□ net volume in litres - AI (315n*)

* 'n' indicates the implied decimal point position

[4-16] When the identification of a variable measure trade item is completed by providing the variable count of trade items contained in it, AI (30) VAR.COUNT must be used to specify the count:

□ When used in combination with AI (02) it denotes the total number of items in the logistic unit.

□ When used in combination with AI (01) it denotes the total number of items within the trade item.

Some roll products cannot be identified according to criteria that have been determined in advance. They are, therefore, classified as variable measure trade items. For these products the following guidelines should be used.

[4-17] The GS1 Application Identifier (8001) indicates that the GS1 Application Identifier data field contains the variable attributes of a roll product.

The variable values of a roll product, N1 to N14, consist of the following data:

□ N1 to N4: slit width in millimetres (width of the roll)

□ N5 to N9: actual length in metres

□ N10 to N12: internal core diameter in millimetres

□ N13: winding direction (face out 0, face in 1, undefined 9)

□ N14: number of splices (0 to 8 = actual number, 9 = number unknown)

It is recommended to include date information whenever it is relevant.

[4-18] If applicable one of the following dates should be given, depending on the type of product :

□ Production date: AI (11) PROD DATE

□ Packaging date: AI (13) PACK DATE

□ Best before date: AI (15) BEST BEFORE

□ Sell by date: AI (16) SELL BY

□ Expiry date: AI (17) EXPIRY

The included date will normally be of the same type as the date indicated on the product itself (often for legal reasons). This allows for consistent tracking and tracing as the date used on the logistic label will match the date marked on the product.

Traceability systems will not work, and possibly legal requirements will not be met if the correct date is not used. AI (15) is a statement about quality (e.g. a bottle of drinking water past its best before date may have diminished quality but it should not be harmful). AI (16) indicates the date specified by the manufacturer as the last date the retailer is to offer the product for sale to the consumer. AI (17) is the date that determines the limit of consumption or use of a product.

The following general rules should be applied when using dates on the GS1 Logistic Label:

[4-19] (Normative) Dates always relate to the GTIN specified on the label as AI (01) GTIN or as AI (02) CONTENT or AI (8006) ITIP or AI (8026) ITIP CONTENT. [GENSPECS, 4.14.2]

[4-20] (Normative) For all of the date types mentioned in rule [4-12] only one date value can be specified on a logistic label. If the trade items contained in the logistic unit have various date values, these cannot be specified on the label. [GENSPECS, 4.14].

[4-21] Best practice for FIFO purposes: When trade items with multiple best before dates are loaded on the logistic unit, the earliest date on any item is used in both the despatch advice and on the label.

[4-22] (Normative) When expressed in barcode form, the date format for each AI is always YYMMDD where:

□ YY provides the tens and units of the year (e.g. 2006 = 06) and is mandatory

□ MM provides the number of the month (e.g. January = 01) and is also mandatory

□ DD provides the number of the day of the relevant month (e.g. second day = 02); For Best Before or Expiry Dates it may not be necessary to specify the day. In that case the field must be filled with two zeroes, and will be interpreted as the last day of the noted month.

The Batch or Lot number of the trade item(s) may be included as AI (10) BATCH/LOT.

[4-23] (Normative) The batch / lot number always relates to the GTIN specified on the label as AI (01) GTIN or as AI (02) CONTENT or AI (8006) ITIP or AI (8026) ITIP CONTENT. [GENSPECS, 4.14.2]

[4-24] (Normative) Only one batch number can be put on a logistic label. If a logistic unit contains products with different batch numbers (at the highest level of packaging), these batch numbers cannot be shown on the label. [GENSPECS, 4.14]

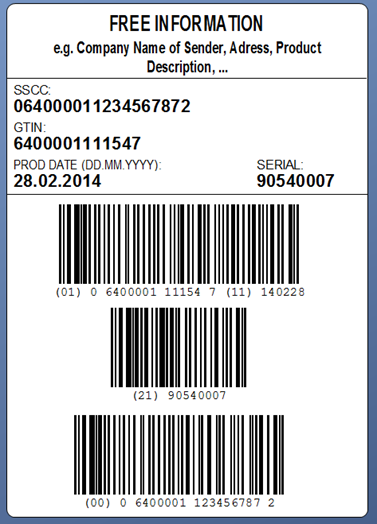

A serial number for the trade item may be included as AI (21) SERIAL.

[4-25] (Normative) The serial number always must be used in combination with a GTIN that is specified on the label as AI (01) GTIN or AI (8006) ITIP. [GENSPECS, 4.14.2]

| AI | Full Title | Data Title | Format (**) |

| 01 | Global Trade Item Number | GTIN | N2 + N14 |

| 02 | GTIN of trade items | CONTENT | N2 + N14 |

| 10 | Batch or Lot Number | BATCH/LOT | N2 + X..20 |

| 11 | Production Date (YYMMDD) | PROD DATE | N2 + N6 |

| 13 | Packaging Date (YYMMDD) | PACK DATE | N2 + N6 |

| 15 | Best Before Date (YYMMDD) | BEST BEFORE or BEST BY | N2 + N6 |

| 16 | Sell By Date (YYMMDD) | SELL BY | N2 + N6 |

| 17 | Expiration Date (YYMMDD) | USE BY | N2 + N6 |

| 21 | Serial Number | SERIAL | N2 + X..20 |

| 30 | Variable Count | VAR. COUNT | N2 + N..8 |

| 310n* | Net Weight, kilograms | NET WEIGHT (kg) | N4 + N6 |

| 311n* | Length or 1st dimension, metres | LENGTH (m) | N4 + N6 |

| 314n* | Area, square metres | AREA (m2) | N4 + N6 |

| 315n* | Net volume, litres | NET VOLUME (l) | N4 + N6 |

| 320n* | Net Weight, pounds | NET WEIGHT (lb) | N4 + N6 |

| 37 | Count of Trade Items or trade item pieces contained in a logistic unit | COUNT | N2 + N..8 |

| 8001 | Roll Products (Width, Length, Core Diameter, Direction, Splices) | DIMENSIONS | N4 + N14 |

| 8006 | Identification of an individual trade item piece | ITIP | N4+N14+N2+N2 |

| 8026 | Identification of pieces of a trade item (ITIP) contained in a logistic unit | ITIP CONTENT | N4+N14+N2+N2 |

(*) 'n' is used to indicate the decimal point position.

(**) Format of the GS1 Application Identifier + Format of the data element

5 How to include transport and customer information

5.1 When would I use this?

5.2 Customer (Receiver) name and address

5.3 Supplier (Shipper) name and address

5.4 Routing code

5.5 Ship for location / ultimate consignee

5.6 Shipment identification

5.7 Consignment identification

5.8 Customer's purchase order number

5.9 Logistic measures

5.10 Handling and processing instructions

5.11 Extract of GS1 Application Identifiers for transport and customer information

Carriers (Logistic service providers) will often not have access to electronic information related to an SSCC. For them the inclusion of additional information is important. Customers / receivers may also not always have access to all the required information.

Typical information used for transport includes ship to postal code, consignment number, and carrier-specific routing and handling information such as a routing code. Typical customer information includes the ship to location, ultimate consignee address, purchase order number, shipment number, etc.

The label facilitates automatic data capture of SSCCs when tracking packages and is also intended to be used for automatic sorting at transport terminals.

Transport information can be used for basic transport and delivery scenarios, but also in support of more advanced scenarios, such as order reconstruction.

Figure 5‑1 Label including transport information

The ship to address is necessary for carriers in order to know the delivery location and to be able to deliver the goods to the right destination.

[5-1] The ship to information must relate to the physical address where the goods need to be delivered.

[5-2]When the goods are delivered via a cross-dock terminal the ship to information must relate to the physical address of the terminal. The final destination address must be specified separately, see paragraph 5.5 Ship for location / ultimate consignee.

[5-3] The exact Ship To location can be included using the Global Location Number (GLN) in AI (410) SHIP TO LOC.

[5-4] Partial identification of the Ship To location can be accomplished by including the postal code in AI (420) SHIP TO POST or AI (421) SHIP TO POST. The use of AI (421) is recommended and has the following structure: Country code (ISO 3166-1 numeric 3 format) followed by postal code (alphanumeric maximum 9 characters).

[5-5] (Normative) AI (420) SHIP TO POST and AI (421) SHIP TO POST must never be used in combination. [GENSPECS, 4.14.1]

The customer name and address may be included as free text:

[5-6] Depending on the country, the address can be expressed by one or several lines.

[5-7] Inclusion of the postal code is strongly recommended.

[5-8] The country code in Non-HRI text should be based on ISO 3166 with alpha 2 code.

The supplier (shipper) name and address may be useful for carriers. The supplier (shipper) name and address may only be included as free text.

[5-9] The supplier (shipper) information may relate to the either the physical address where the goods came from or the business address of the supplier (shipper).

[5-10] Depending on the country, the address can be expressed by one or several lines.

[5-11] Inclusion of the postal code is strongly recommended.

[5-12] The country code in Non-HRI text should be based on ISO 3166 with alpha 2 code.

[5-13] It is recommended to depict the supplier (shipper) name and address in a smaller font than the customer (receiver) name and address.

The routing code is a code used by the carrier to efficiently steer logistic units through its network. Its content and structure are at the discretion of the carrier issuing the code. The routing code is intended to provide carriers such as parcel networks with a migration path towards full adoption of the SSCC.

[5-14] The routing code can be included using AI (403) ROUTE.

[5-15] The routing code can also be included as free text information.

If the details of the ultimate consignee are known at the time when the logistic unit is constructed and labelled, it is strongly recommended to include the location number of the ultimate consignee using the AI (413) SHIP FOR LOC.

[5-16] The ultimate consignee location is included using the Global Location Number (GLN) in AI (413) SHIP FOR LOC.

[5-17] The ultimate consignee name and address may also be included as free text information.

The shipment identification can be included on the label to ensure logistic units belonging to the same shipment will be delivered together.

The GS1 Identification Key for shipments is the Global Shipment Identification Number (GSIN). The format of the GSIN is as follows:

| GS1 Application Identifier | Global Shipment Identification Number (GSIN) | ||

| GS1 Company Prefix | Shipper reference | Check digit | |

| 4 0 2 | N1 N2 N3 N4 N5 N6 N7 N8 N9 N10 N11 N12 N13 N14 N15 N16 | N17 | |

The GS1 Company Prefix (GCP) is assigned by a GS1 Member Organisation to the company creating the shipment.

The Shipper Reference is a serial number created by the shipper. The simplest way to allocate the serial number is sequentially, for example ….00000, …00001, …00002.

The Check Digit is calculated using the algorithm defined by GS1. [GENSPECS, 7.9.1], for a check digit calculator see [CHECK].

[5-18] The shipment identification should be included using the Global Shipment Identification Number (GSIN) in AI (402) GSIN.

The consignment identification can be included on the label to ensure completeness of a group of logistic units being transported together under the same transport contract. This can be important in cases where the logistic units are transported by secondary transport operators, only responsible for part of the total journey (for example via rail or ocean).

The GS1 Identification Key for consignments is the Global Identification Number for Consignment (GINC). The format of the GINC is as follows:

| GS1 Application Identifier | Global Identification Number for Consignment (GINC) | |

| GS1 Company Prefix | Consignment reference ──────────────────────────────> | |

| 4 0 1 | N1 ...Ni Xi+1 ...variable lengthXj (j<=30) | |

The GS1 Company Prefix (GCP) is assigned by a GS1 Member Organisation to the company that allocates the GINC - here the freight forwarder or carrier of the transport units.

The Consignment Reference is a serial number created by the carrier or freight forwarder. Typically, the GINC is used by freight forwarders to instruct transport providers, and holds the Master Way Bill (MWB) Number, for example a Master Airway Bill (MAWB) or a Master Bill-of-lading (MBL).

[5-19] The consignment identification should be included using the Global Identification Number for Consignments (GINC) in AI (401) GINC.

The customer's purchase order number can be included on the label.

[5-20] The customer's purchase order number can be included using AI (400) ORDER NUMBER.

Weight information about the individual logistic unit as well as for the total shipment (for example in the form of nnn/nnn) can be useful information when transiting through intermediate warehouses. Depending on the situation, the label issuer may need to specify:

■ Weight: 50 / 300 the parcel weight and the shipment weight are known.

■ Weight: - / 300 only the total weight of the shipment is known.

■ Weight: 50 / - only the weight of the parcel is known. Total weight is unknown.

Besides weight information also volume, area or dimensions may be of importance.

[5-21] The use of one or more of the following measures is available depending on the nature of the logistic unit:

□ logistic weight: kilograms - AI (330n*), pounds - AI (340n*)

□ logistic volume: litres - AI (335n*), cubic metres - AI (336n*), quarts - AI (362n*), gallons (US) - AI (363n*), cubic inches - AI (367n*), cubic feet - AI (368n*), cubic yards - AI (369n*)

□ area: square metres - AI (334n*), square inches - AI (353n*), square feet - AI (354n*), square yards - AI (355n*)

□ kilograms per square metre - AI (337n*)

□ length: meters - AI (331n*), inches - AI (341n*), feet - AI (342n*), yards - AI (343n*)

□ width: meters - AI (332n*), inches - AI (344n*), feet - AI (345n*), yards - AI (346n*)

□ height: meters - AI (333n*), inches - AI (347n*), feet - AI (348n*), yards - AI (349n*)

□ * 'n' indicates the implied decimal point position

Free Format

The label issuer can include text or symbols indicating manual handling instructions on the label as free text.

For example:

Symbol 1 (0- 15 kg) Symbol 2 (>15-25 kg) Symbol 3 (>25 kg)

![]()

![]()

| AI | Full Title | Data Title | Format (**) |

| 330n* | Logistic weight, kilograms | GROSS WEIGHT (kg) | N4+N6 |

| 331n* | Length or first dimension, metres | LENGTH (m), log | N4+N6 |

| 332n* | Width, diameter, or second dimension, metres | WIDTH (m), log | N4+N6 |

| 333n* | Depth, thickness, height, or third dimension, metres | HEIGHT (m), log | N4+N6 |

| 334n* | Area, square metres | AREA (m2), log | N4+N6 |

| 335n* | Logistic volume, litres | VOLUME (l), log | N4+N6 |

| 336n* | Logistic volume, cubic metres | VOLUME (m3), log | N4+N6 |

| 337n* | Kilograms per square metre | KG PER m\B2 | N4+N6 |

| 340n* | Logistic weight, pounds | GROSS WEIGHT (lb) | N4+N6 |

| 341n* | Length or first dimension, inches | LENGTH (i), log | N4+N6 |

| 342n* | Length or first dimension, feet | LENGTH (f), log | N4+N6 |

| 343n* | Length or first dimension, yards | LENGTH (y), log | N4+N6 |

| 344n* | Width, diameter, or second dimension, inches | WIDTH (i), log | N4+N6 |

| 345n* | Width, diameter, or second dimension, feet | WIDTH (f), log | N4+N6 |

| 346n* | Width, diameter, or second dimension, yard | WIDTH (y), log | N4+N6 |

| 347n* | Depth, thickness, height, or third dimension, inches | HEIGHT (i), log | N4+N6 |

| 348n* | Depth, thickness, height, or third dimension, feet | HEIGHT (f), log | N4+N6 |

| 349n* | Depth, thickness, height, or third dimension, yards | HEIGHT (y), log | N4+N6 |

| 353n* | Area, square inches | AREA (i2), log | N4+N6 |

| 354n* | Area, square feet | AREA (f2), log | N4+N6 |

| 355n* | Area, square yards | AREA (y2), log | N4+N6 |

| 362n* | Logistic volume, quarts | VOLUME (q), log | N4+N6 |

| 363n* | Logistic volume, gallons U.S. | VOLUME (g), log | N4+N6 |

| 367n* | Logistic volume, cubic inches | VOLUME (i3), log | N4+N6 |

| 368n* | Logistic volume, cubic feet | VOLUME (f3), log | N4+N6 |

| 369n* | Logistic volume, cubic yards | VOLUME (y3), log | N4+N6 |

| 400 | Customer's Purchase Order Number | ORDER NUMBER | N3 + X..30 |

| 401 | Global Identification Number for Consignments (GINC) | GINC | N3+X..30 |

| 402 | Global Shipment Identification Number (GSIN) | GSIN | N3+N17 |

| 403 | Routing Code | ROUTE | N3+X..30 |

| 410 | Ship To - Deliver To: GS1 Global Location Number (GLN) | SHIP TO LOC | N3+N13 |

| 413 | Ship For - Deliver For - Forward To: GS1 Global Location Number (GLN) | SHIP FOR LOC | N3+N13 |

| 420 | Ship To - Deliver To: Postal code within a single postal authority | SHIP TO POST | N3 + X..20 |

| 421 | Ship To - Deliver To: Postal code with ISO 3166 country code | SHIP TO POST | N3+N3+X..9 |

| (*) 'n' used to indicate the decimal point position. (**) Format of the GS1 Application Identifier + Format of the data element | |||

6 Label lay-out rules

6.1 Top building block

6.2 Middle building block

6.3 Bottom building block

6.4 Rules related to label segments

The top building block may include any text or graphics. The name and address of the sender and receiver are typical examples. In many instances companies may also wish to add specific graphics to a label (e.g., company logos).

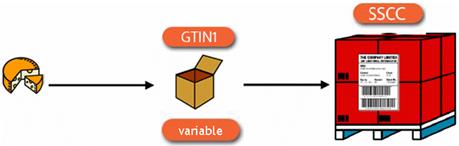

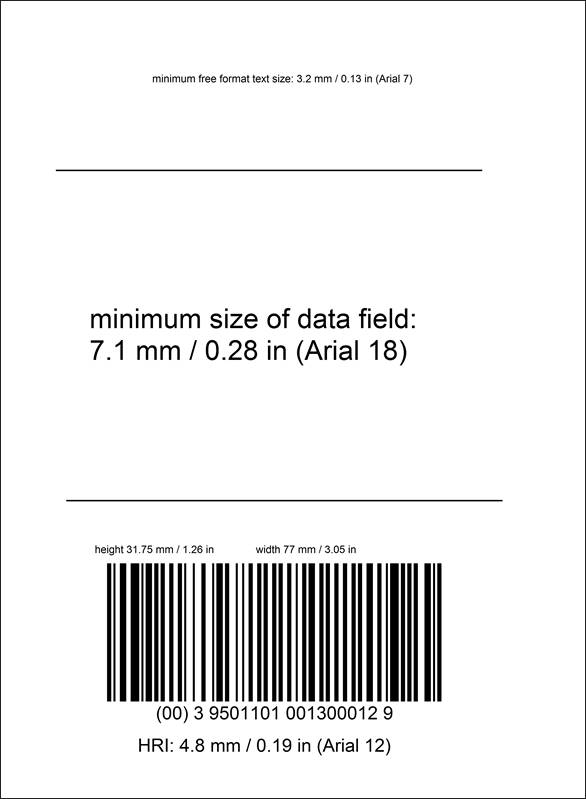

[6-1] (Normative) All text shall be clearly legible and no less than 3 millimetres / 0.118 inches high. [GENSPECS, 6.6.4.4]

The middle building block contains non-HRI text reflecting the information represented in barcode(s) using data title rather than AIs, and optionally additional information not represented in barcodes (preferably including data titles).

[6-2] All barcoded data elements must also be included as text with data titles.

[6-3] (Normative) The data content should be at least 7 mm (0.28 inch) in height [GENSPECS, 6.6.4.2]

[6-4] A GS1 2D barcode, if used, should be placed to the right of the text within the middle building block.

6.2.1 Data titles

Data titles are the standard abbreviated descriptions of element strings used to support the human interpretation of encoded data. Data titles should be used adjacent to all data fields included in the middle building block.

![]() Note: Data Titles may also be used adjacent to barcodes and HRI.

Note: Data Titles may also be used adjacent to barcodes and HRI.

[6-5] (Normative) Data titles should be provided for all AIs encoded in the barcodes.

[6-6] (Normative) If there is no language agreed between trading partners, data titles must be printed in English. A second language may be added. For English data titles, the exact data titles as specified in the 'GS1 General Specifications' should be used. [GENSPECS, 6.6.4.2]

[6-7] Data titles should be presented in UPPERCASE.

[6-8] To avoid any confusion, the data title for dates may be followed by the chosen format, e.g. BEST BEFORE (dd.mm.yyyy): 24.12.2013. This may be different from the format used within the barcode which is always YYMMDD.

The bottom building block contains the GS1-128 barcode(s) including their human readable interpretation (HRI).

GS1-128 is a special version or subset of Code 128.

[6-9] (Normative) GS1-128 barcodes must be distinguished from Code 128 barcodes by the use of the special Function 1 character (FNC1) after the start character.

An enlarged section of the first part of a GS1-128 barcode showing the FNC1 in blue is shown below.

Figure 6‑1 . FNC1 character in GS1-128 barcode.

![]()

Enlarged section of first part of a GS1-128 barcode

showing the Function 1 character in blue

GS1 Application Identifiers

Each data field in a GS1-barcode is preceded by a GS1 Application Identifier (AI). GS1 Application Identifiers are used to identify the meaning and format of the data following each AI.

The data fields are either of fixed or variable length, depending on the AI. There is a range of AIs for additional data, such as weight, area or volume. Full details of all the GS1 Application Identifiers can be found in the 'GS1 General Specifications' [GENSPECS].

[6-10] All the data in each GS1-128 barcode is denoted by the use of GS1 Application Identifiers, which specify the format of the data which follows them. This data may be numeric only, alphanumeric, fixed or variable in length.

Concatenation

A GS1 Application Identifier and the data that follows it are known as an element string, and several element strings may be shown in one GS1-128 barcode. This joining together of element strings is known as concatenation.

Concatenation is an effective means for encoding several AIs in a single barcode and should be used to save label space and optimise scanning operations.

[6-11] It is best practice is to encode data of fixed length before any variable data within a GS1-128 barcode

[6-12] The order in which the element strings appear in GS1-128 barcodes is not specified. Quality software contains optimisation procedures, which improves scanning and printing

[6-13] (Normative) The SSCC, defined by AI (00), shall always appear in the lowest barcode on the label [GENSPECS, 6.6.4.1.1].

[6-14] The SSCC can be alone or concatenated with other data in the same barcode. Concatenation shall not be used with SSCC on cartons and outer cases and on A6 / 4x6 labels.

X-dimension (Symbol size)

The X-dimension is the specified width of the narrowest element in a barcode symbol.

[6-15] (Normative) The allowed X-dimension range for the GS1-128 barcode symbol is between 0.495 mm (0.0195") and 0.94 mm (0.0370"). The target X-dimension recommended for the GS1-128 barcode symbol is 0.495 mm (0.0195"). [GENSPECS, 5.9.3.5, table 5].

[6-16] When multiple barcodes are used it is recommended to use similar X-dimensions. This helps scanning systems to work more effectively.

[6-17]Note that using an X-dimension at the higher end of the permitted range can support consistent scanning when the barcode might be used in challenging application environments (e.g., freezing can degrade print quality).

Barcode height

[6-18] (Normative) A minimum height of at least 31.75 mm (1.250") applies to all the GS1-128 barcodes on the label. The minimum symbol height indicated is for bar height only and does not include the Human Readable Interpretation. [GENSPECS, 5.9.3.5, table 5]

Quiet zones / Light margins

[6-19] (Normative) Barcodes shall be printed with quiet zones (or light margins) at each side. The quiet zones must be at least 10 X-dimension (10 X) in width. Centred barcodes will help ensure the quiet zones are respected.

Orientation and placement

[6-20] (Normative) Horizontal orientation (picket fence orientation) of barcode symbols must be used on logistic units. In other words, the bars and spaces shall be perpendicular to the base on which the logistic unit stands.

Human readable interpretation

[6-21] All the data shown in each barcode should be provided below each symbol. Brackets (parentheses) are normally printed around each AI but these must not be encoded in the barcode.

[6-22] (Normative) The data must be shown in characters at least 3 mm high and clearly legible. [GENSPECS, 4.15]

AI uniqueness (no repetition)

[6-23] Each GS1 Application Identifier (AI) may only occur once on a logistic label.

The order and top/down alignment of label segments may vary depending on the size of the logistic unit and the business process being served.

[6-24] (Normative) Within each separate label segment the building blocks must be placed according to the lay-out defined in section 2.2 . Building blocks [GENSPECS, 6.6.3.2]

[6-25] (Normative) A segment holding the SSCC shall always be present, and shall be positioned under any other segments. [GENSPECS, 6.6.3.1]

[6-26] Segments may be printed as separate labels in which case they should be placed vertically in close proximity of each other, with the segment containing the SSCC at the bottom. When segments are added separately, care should be taken not to obscure existing segments.

[6-27] The carrier segment may be replaced during the journey of the logistic unit. The original SSCC should be preserved in that case, either by leaving the segment holding the SSCC intact, or by reproducing the original SSCC on the new label / label segment.

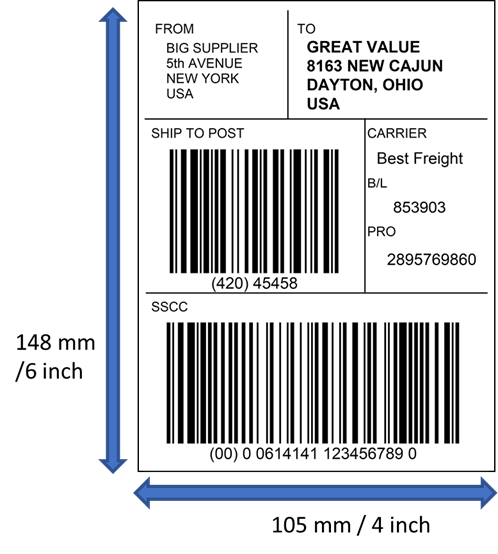

7 Size of the GS1 Logistic Label

The label may be any size. Factors influencing label dimensions include the amount of data required, the X-dimension of the barcodes used, and the dimensions of the logistic unit to be labelled. The business requirements for most users of GS1 Logistic Labels are met by using one of following:

A. Compact label

■ A6 (105 mm x 148 mm) or 4 x 6 inch, which is particularly suitable when only the SSCC, or the SSCC and limited additional data, is encoded.

Figure 7‑1 dimensions A6 / 4 x 6 inch label

B. Large label

■ A5 (148 mm x 210 mm) or 6 x 8 inch, suitable when additional data such as trade item data are needed. Applied for example on pallet labels.

Figure 7‑2 dimensions of A5 / 6 x 8 inch label

C. Other size labels

■ Other label dimensions are typically variations driven by data requirements or logistic unit size.

8 Label placement

8.1 Label placement on larger logistic units (pallets, roll cages, etc.)

8.2 Label placement on smaller logistic units (including parcels)

8.3 Label placement on stacked pallets

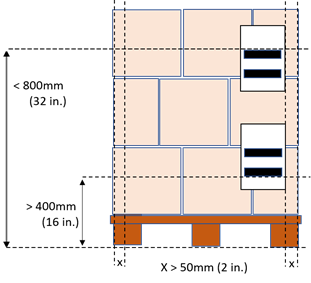

[8-1] (Normative) For all types of pallets the barcodes SHALL be positioned between 400 millimetres (16 inches) and 800 millimetres (32 inches) from the base of the pallet. For pallet less than 400 millimetres (16 inches) high, the barcode SHALL be placed as high as possible while protecting the barcode. [GENSPECS, 6.7.1.1]

[8-2] (Normative) The symbol including its Quiet Zones, SHALL be at least 50 millimetres (2.0 inches) from any vertical edge to avoid damage. [GENSPECS, 6.7.1.1]

[8-3] Each logistic unit should at the minimum have one label. For pallets it is recommended that two sides of the item are labelled the exact same data, to ensure one label is always visible (e.g. pallets that are stored either long or short edge facing). On rolling logistic units a label on one side is usually sufficient.

![]() Note: There is no regulation that specifies where the labels should be placed - to the left, in the middle, or to the right on these sides - but as most forklift operators are right-handed, the most ergonomically correct scanning is done when the labels are placed to the right of each side.

Note: There is no regulation that specifies where the labels should be placed - to the left, in the middle, or to the right on these sides - but as most forklift operators are right-handed, the most ergonomically correct scanning is done when the labels are placed to the right of each side.

Figure 8‑1 Example of label placement on pallets

![]() Note: This diagram is an example only and in some cases it may be necessary for two labels to be placed on opposite sides of the pallet.

Note: This diagram is an example only and in some cases it may be necessary for two labels to be placed on opposite sides of the pallet.

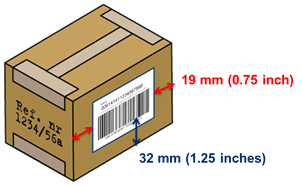

[8-4] (Normative) For cartons and outer cases, symbol placement will vary slightly in practice, however the target placement for the bottom of the barcode is 32 millimetres (1.25 inches) from the natural base of the item. [GENSPECS, 6.7.1.2]

[8-5] (Normative) The symbol including its Quiet Zones, should be at least 19 millimetres (0.75 inch) from any vertical edge to avoid damage. [GENSPECS, 6.7.1.2]

[8-6] Each logistic unit should at the minimum have one label.

Figure 8‑2 Label placement on cases

![]() Carton / Outer Case Labels: For Carton / Outer Case Labels the same guidelines apply. In situations where both a Carton / Outer Case Label as well as a Logistic Label need to be applied on the case, the recommendation is to place the GS1 Logistic Label to the left of the Carton / Outer Case Label, and to ensure that the information on the Carton / Outer Case Label remains visible.

Carton / Outer Case Labels: For Carton / Outer Case Labels the same guidelines apply. In situations where both a Carton / Outer Case Label as well as a Logistic Label need to be applied on the case, the recommendation is to place the GS1 Logistic Label to the left of the Carton / Outer Case Label, and to ensure that the information on the Carton / Outer Case Label remains visible.

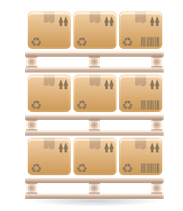

Stacked pallets, also referred to as sandwich pallets, are groups of pallets that are stacked for shipment.

[8-7] When pallets are stacked they should be considered independent logistic units (see Figure below), each pallet should be identified with a unique SSCC.

Figure 8‑3 Stacked Pallets as Independent Logistic Units

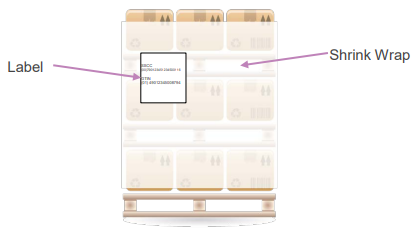

[8-8] If the group will be shipped as a unit and is physically joined using shrink-wrap, straps, or similar means (see Figure below), the group should be considered as a single logistic unit as well and an additional SSCC should be assigned to the stacked pallet group.

![]() Note: In cases where the stacked pallets are shipped as one single unit, the original labels should not be visible. A master label with the SSCC for the pallet group should be applied to the outside of the wrapping. The wrap and master label may be removed upon receipt and the labels for each stacked pallet will be used to identify each pallet for subsequent processing.

Note: In cases where the stacked pallets are shipped as one single unit, the original labels should not be visible. A master label with the SSCC for the pallet group should be applied to the outside of the wrapping. The wrap and master label may be removed upon receipt and the labels for each stacked pallet will be used to identify each pallet for subsequent processing.

Figure 8‑4 Stacked Pallets combined into a single logistic unit

9 Implementation considerations

9.1 Best practice processes by role

9.2 Label implementation scenarios

9.3 Shipper / Supplier

9.4 Carrier

9.5 Receiver / Customer

Usually the shipper of the goods will create the logistic label and apply it to the logistic unit. Responsibility for the correctness of all the information contained on the label is assumed to rest with the shipper.

If it is not the shipper but the carrier or receiver creating the label, or replacing the label, or adding additional information to the label, this party is responsible for content and quality its own data and its compliance with data already present.

The table below lists various parties and how they may use the label in their business processes depending on the role they play.

| Role of party | Best practices |

| Raw Materials Supplier | Provides a pallet label on pallets of raw materials when shipping to a supplier. |

| Manufacturer/Supplier | Receives raw materials by scanning pallet labels and stores raw materials using these labels to identify the raw materials and to provide traceability. When producing finished goods will produce a new pallet label and use this as the identifier for internal storage. The pallet label's SSCC will also be used to identify stock when loaded onto outbound transport for transfer between distribution centres and for customers. If building a new pallet for a business customer they will affix a new pallet label. |

| Consolidator | Scans the pallet label to record the stock received. If storing stock will use the pallet label's SSCC as the identifier. If sending out the received pallets they will scan the pallet labels again when loading outbound transport. If breaking down and rebuilding pallets they will remove the old pallet labels and replace them with new pallet labels. |

| Distribution Centre (of customer retailer) | Scans the pallet label to record the stock received. If storing stock will use the pallet label's SSCC as the identifier. If building a new pallet for a business customer they will affix a new pallet label. |

| Customer (typically a business customer) | Scans the pallet label to record the stock received. |

| Warehouse Service Provider / Co-packer | Receive the stock using the inbound pallet label. Add value to the stock then build stock onto new pallets and affix a new pallet label. Retain a record of the relationship between the stock in the old consignment and stock in the new consignment. |

| Cross-docking between DCs | If dispatching or transferring the pallets between distribution centres, sending DC will scan the pallet labels when loading internal and outbound transport and scan them again to acknowledge receipt. |

| Transport Service Provider | Scans the goods upon loading to record the logistic units. Scans the goods upon unloading to record the logistic units. Provides status information on logistic unit level. |

Depending on the business scenario various label formats may be implemented. Some typical variants are:

■ A pre-printed SSCC-only label is a good option when there is no 'print and apply capability'. Pre-printed SSCC labels are applied to a logistic unit, scanned and then electronically associated to the GTINs and all related data. A pre-printed label can be applied anywhere in the supply chain (from when the pallet is produced to when it is received by a customer).

■ A production label containing supplier and trade item information can be printed and applied at the time the pallet (logistic unit) is manufactured. This label can stay with the pallet/logistic unit through the supply chain if it is delivered in a full pallet quantity to the customer.

■ A picked pallet label is printed and applied at the time the pallet (logistic unit) is picked for a customer, and may contain supplier, customer and carrier information.

■ An existing SSCC label (e.g. pre-printed SSCC-only label or production label) is already applied, and the carrier or customer data is added by applying an additional label segment.

The shipper may be the supplier or a logistic service provider (LSP) acting on behalf of the supplier.

If the LSP acts as the shipper, after the supplier receives an order an Instruction to Despatch will be sent to the LSP. The LSP should be able to pick and load the shipment according to the instructions, this could include a reconfiguration of existing logistic units.

9.3.1 Pre-requisites

[9-1] The shipper / supplier should have the ability to communicate electronically.

[9-2] Trade item data alignment is a prerequisite in order to enable efficient shipping and receiving process. The shipper / supplier should ensure that master data have been communicated to the receiver / customer.

[9-3] Each warehouse should have scanners to read the GS1-128 barcode(s) printed on the labels

9.3.2 Creating the SSCC

[9-4] SSCC numbers should be generated out of the logistic management system, e.g. the warehouse management system (WMS) or ERP.

[9-5] The shipper should use its own GS1 Company Prefix to generate the SSCC.

Note: If the shipper uses a cloud service to generate labels, SSCCs are usually generated from the IT solution provider's GS1 Company Prefix. This may lead to weaker traceability and is an incorrect use of the GS1 standards.

[9-6] SSCCs that have been created should be archived for traceability purposes.

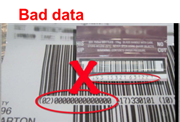

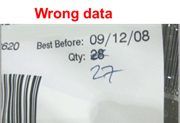

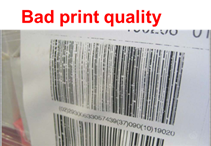

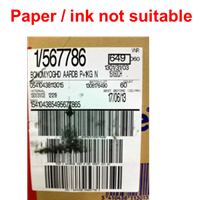

Figure 9‑1 Examples of system integration problems

9.3.3 Printing the label

[9-7] Standard paper sizes are recommended, e.g. A5 or A6.

[9-8] Label material and ink have to be compatible. Material or ink which is sensitive to heat is not acceptable, e.g. avoid thermal paper that changes colour when exposed to heat or sun, and inks that can be easily smudged.

[9-9] It is recommended to print black barcodes on a white background.

[9-10

[9-11] The label printer should be checked regularly to ensure it is up and running, and serviced and calibrated correctly.

Label verification

[9-12] Label verification during implementation should include three different levels (see appendix A for a detailed implementation verification procedure):

□ Visual check of a label

□ Relevant information on a label

□ Technical parameters = barcode symbol verification.

[9-13] After implementation, in the operational phase, regular verifications should be performed to maintain label quality.

Figure 9‑2 Examples of printing-related problems

![]()

9.3.4 Attaching the label

It is important the right label(s) is / are attached to the right logistic unit and the labels are scannable.

[9-14] When not attached automatically, an option is to print labels for each logistic unit one at the time in order to limit risk of applying the wrong label.

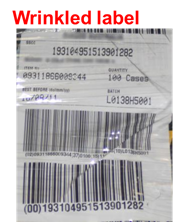

[9-15] Other common problems to avoid are:

□ Wrinkling when applying the label.

□ Incorrect placement of the label.

□ Obscured label (over wrapping / seal).

Figure 9‑3 Examples of placement problems

9.3.5 Sending the transport instruction

[9-16] If available at the time that the transport instruction is sent to the LSP. The transport instruction should specify the SSCCs of the logistic units to be transported.

9.3.6 Staging / Loading the logistic units

[9-17] Only loaded pallets should be scanned. This ensures correct delivery information for despatch advice / ASN and transport documents.

9.3.7 Sending the Despatch Advice / ASN

[9-18] The Despatch Advice / ASN should be sent upon staging / loading of the goods, in order to maximise the chance that the information matches the actual shipment.

[9-19] The Despatch Advice / ASN should specify for each logistic unit the SSCC and the contained trade items.

[9-20] The variable data related to the trade item must match the information of the actual goods present on the logistic unit.

The optimal collaboration between a supplier (shipper) - carrier - customer (receiver) is crucial for an efficient shipping and receiving process, and the carrier plays a central role.

9.4.1 Pre-requisites

[9-21] The carrier should have the ability to communicate electronically

[9-22] Each truck should have a scanner to read the barcode(s) printed on the labels

9.4.2 Processing the Transport Instruction

[9-23] In the Transport Instruction information on the logistic units that need to be transported may be included. If that is the case the carrier should ensure that this information is communicated to the person in charge of the transport execution, for example the driver.

9.4.3 Loading the logistic units

[9-24] The carrier may scan the label in order to register which logistic units were loaded.

[9-25] When a label is already present additional transport data is best added on an extra label, attached adjacent to and preferably above the already present label. When a label is added separately, care should be taken not to obscure the existing label. The extra label should only contain data not yet present on the other label.

Any additional labels that contain information already present on other labels pose a potential risk for non-scans/confusion.

Figure 9‑4 Example of problems occurring during transport

![]()

![]()

![]()

When no label is present

[9-26] When no label is present upon collecting of the goods the carrier may generate the SSCC based on its own GS1 Company Prefix and for example create an SSCC-only label or a transport label.

9.4.4 Unloading the logistic units

[9-27] The carrier may scan the label in order to register which logistic units were unloaded.

9.4.5 Sending the Transport Status Notification / Information on Delivery (IOD)

[9-28] Upon completion of the delivery the carrier should send a Transport Status Notification informing his client on the completion of the transport order and on any discrepancies that occurred.

The receiver may be the customer, for example a retailer, or a logistic service provider receiving the goods on behalf of the customer.

9.5.1 Pre-requisites

[9-29] The receiver / customer should have the ability to communicate electronically

[9-30] Master data of the trade item need to be in place. Unknown items cannot be received efficiently.

[9-31] Each warehouse should have scanners to read the barcode(s) printed on the labels

[9-32] Each warehouse should have a warehouse management system to support the receiving process

[9-33] Rejection of delivery (or otherwise) without Despatch Advice / ASN should be included in the contract

9.5.2 Processing the Despatch Advice / ASN

[9-34] The Despatch Advice / ASN should be received and processed into the receivers' system before the goods arrive.

9.5.3 Inspecting and registering the received logistic units

Depending on the agreement between the supplier and receiver the SSCC may be scanned and the goods accepted as complete as indicated in the Despatch Advice / ASN. Alternatively, the receiver may wish to check the logistic units to confirm that the contents are as agreed in the Despatch Advice / ASN and also to check for any damage. This would apply particularly where the logistic unit contains multiple products. Checks will depend on the contract between the receiver and their supplier.

[9-35] Labels should not be removed before put away is complete, and preferably kept to assist traceability if necessary

[9-36] When the SSCC is scanned it should match the information in the Despatch Advice / ASN, and the received amount should be automatically added to the Warehouse system and update the stock level.

Figure 9‑5 . Example of issues occurring at receipt

9.5.4 Sending the receiving advice

The receiver can use the Receiving Advice message to notify the supplier that the goods have been received. He may confirm receipt of all products or only those where there may be a problem e.g. damaged or missing goods. This will allow the supplier to replace the missing or damaged goods promptly. For maximum benefit, the supplier should have an automated process to efficiently recognise and action any errors as notified by the customer.

9.5.5 Storing the goods

[9-37] Where possible, the goods should be stored preserving the SSCC relationship so that they can be traced when necessary.

9.5.6 Handling quality issues found after goods receipt

If there is damage to the goods, or any other product issues, then the supplier (and haulier if not managed or owned by the supplier) should be notified so that they can make adjustment to their invoice before sending to the customer.

10 Practical examples

10.1 SSCC-only label

10.2 GS1 Logistic Label for homogeneous logistic unit

10.3 GS1 Logistic Label for homogeneous logistic unit with variable measure items

10.4 GS1 Logistic Label for orderable pallet

10.5 GS1 Logistic Label for logistic unit that is a single trade item

10.6 GS1 Logistic Label for mixed pallet

10.7 GS1 Logistic Label with logistic unit and transport information in separate segments

10.8 GS1 Logistic Label with supplier, customer and transport segments

10.9 GS1 Logistic Label with transport information including postal code

10.10 GS1 Logistic Label with transport information including routing code and GINC

10.11 GS1 Logistic Label for parcel (SSCC-only)

10.12 GS1 Logistic Label for parcel (including routing code)

10.13 GS1 Logistic Label for parcel (including a GS1 2D barcode)

10.14 GS1 Logistic Label with identification of individual trade item piece - AI (8006)

Source: [GENSPECS]

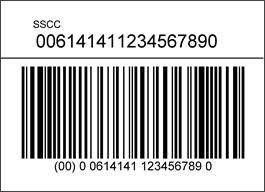

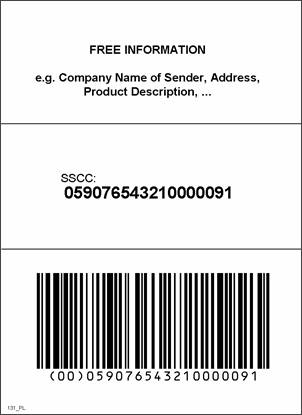

This example shows a label containing only an SSCC. Such labels can be applied at production time, but also during transport or receipt when no label is present on the logistic unit.

Building blocks (top-down):

■ Text with Data Titles: SSCC

■ Barcodes + HRI: AI (00)

|

| |

|

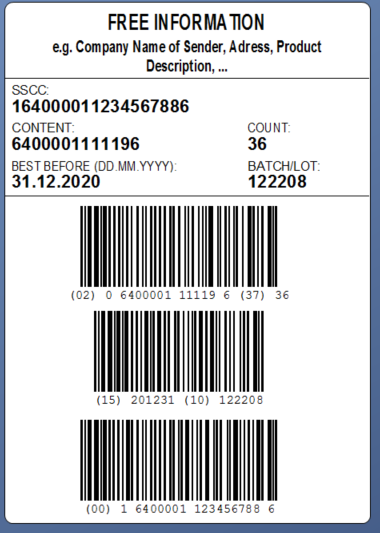

| |

| Mandatory data | SSCC with AI (00) |

| Optional data | GTIN2 with AI (02) + count of trade items contained with AI (37) batch / lot number with AI (10) one of the following dates if applicable: production date with AI (11), packaging date with AI (13), best before date with AI (15), expiry date with AI (17) |

Based on [ELL] example

|

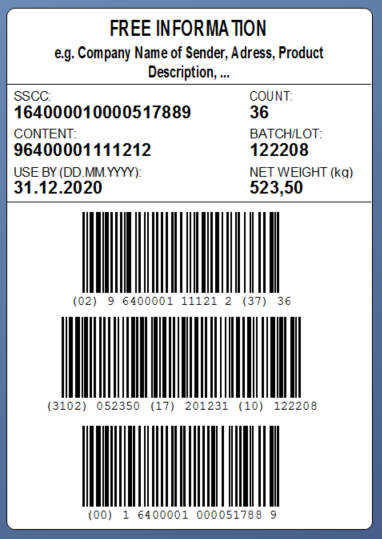

| |

|

| |

| Mandatory data | SSCC with AI (00) |

| Optional data | GTIN1 leading with '9' with AI (02), count of trade items contained with AI (37) one of the measures: net weight (kg) with AI (310n), length (m) with AI (311n), area (m2) with AI (314n), net volume (l) with AI (315n), variable count with AI (30), batch / lot number with AI (10) one of the following dates if applicable: production date with AI (11), packaging date with AI (13), best before date with AI (15), expiry date with AI (17) |

Based on [ELL] example

|

| |||

|

| |||

| Mandatory data | SSCC with AI (00) | ||

| Optional data | GTIN2 with AI (02) count of trade items contained with AI (37) | OR | GTIN3 with AI (01)* |

| batch / lot number with AI (10) one of the following dates if applicable: production date with AI (11), packaging date with AI (13), best before date with AI (15), expiry date with AI (17) | |||

Based on [ELL] example

If a logistic unit includes only one trade item, a logistic label should contain the following data:

|

| |

|

| |

| Mandatory data | SSCC with AI (00) |

| Optional data | GTIN with AI (01) batch / lot number with AI (10) - if applicable serial number with AI (21) - if applicable one of the following dates if applicable: production date with AI (11), packaging date with AI (13), best before date with AI (15), expiry date with AI (17) |

Based on [ELL] example

|

| |

|

| |

| Mandatory data | SSCC with AI (00) |

| Optional data | none |

Source [ELL]

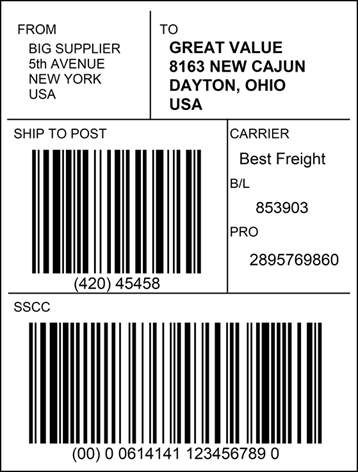

Source [GENSPECS]

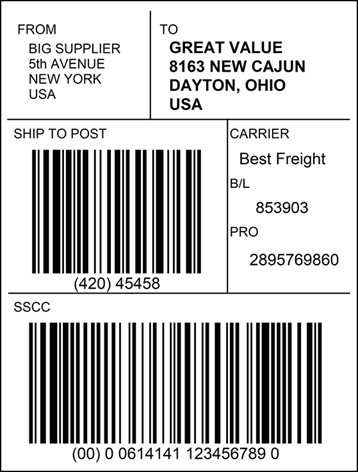

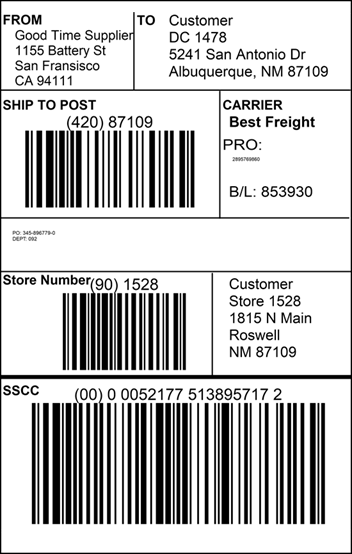

This example shows a case label that may be applied at the time of transport. Besides the SSCC it contains information on the route and destination.

Segments and building blocks (top-down):

■ Carrier Segment

□ Free Format: FROM, TO

□ Barcodes and HRI: SHIP TO POST

□ Text with Data Titles: CARRIER; B/L, PRO

■ Supplier Segment

□ Barcodes and HRI: SSCC; AI (00)

Source [GENSPECS]

This example shows a case label that may be applied in a cross-docking scenario. Besides the SSCC it contains transport information and information on the final customer destination.

Segments and building blocks (top-down):

■ Carrier segment:

□ Free Format: FROM, TO

□ Barcodes and HRI: SHIP TO POST

□ Text with Data Titles: Carrier; B/L, PRO

■ Customer segment

□ Free Format: PO, DEPT

□ Barcodes and HRI: Store Number

□ Text with Data Titles: Customer

■ Supplier segment

□ Barcodes and HRI: SSCC; AI (00)

In this example, the postal code is used with the GS1 Application Identifier (421).

Source: STILL

In this example, the routing code is used with the GS1 Application Identifier (403)

Source [GENSPECS]

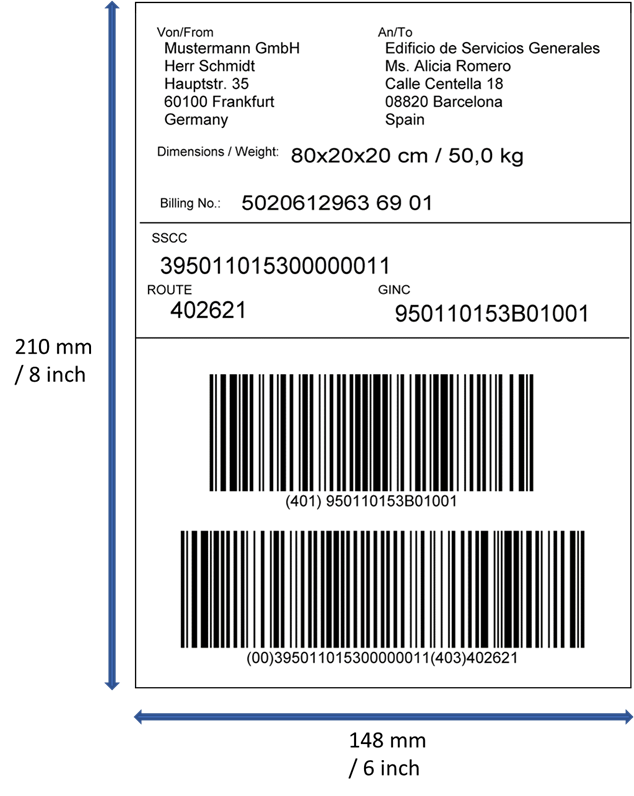

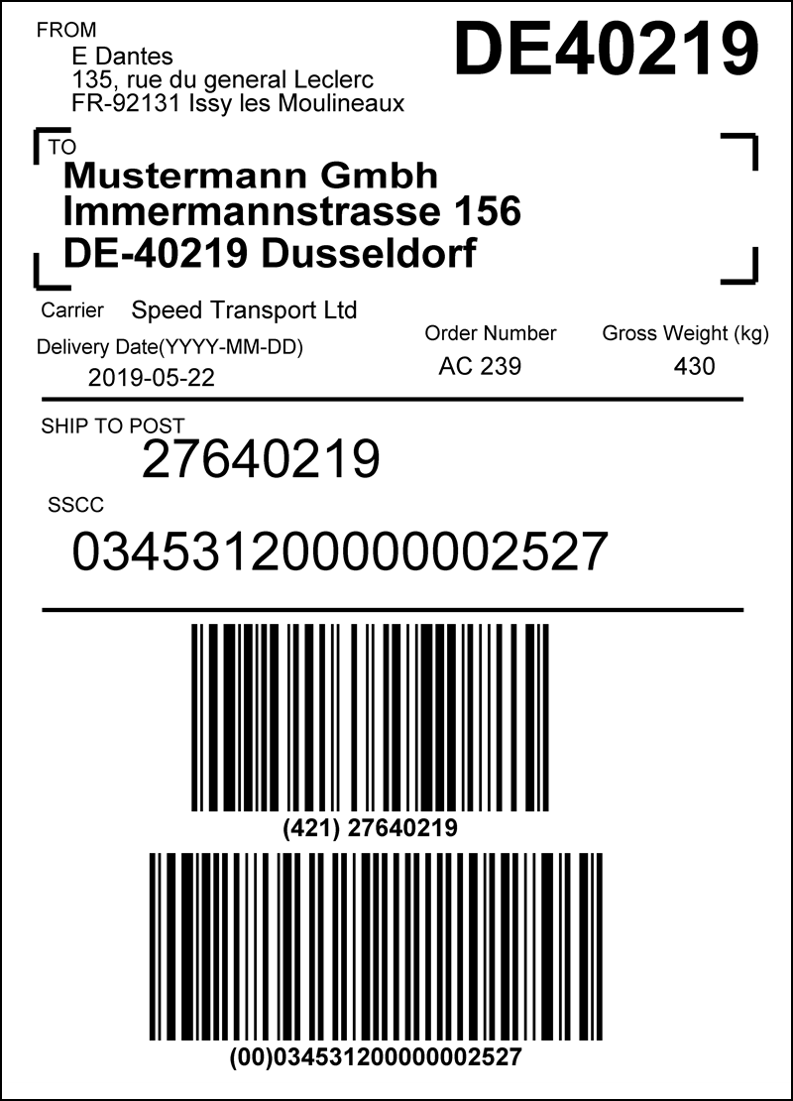

This example shows a pallet label that may be applied at the time of transport. Besides information on the logistic unit it contains information on the route and destination.

Building blocks (top-down):

■ Free Format: Von/From, An/To

■ Text with Data Titles: SSSC, ROUTE; Dimensions / Weight; Billing No.

■ Barcodes and HRI: AI (403), AI (401), AI (00)

This example shows a parcel label that only contains name and address information and an SSCC. This shipper-assigned label would be suitable for any parcel carrier network since it does not contain carrier-specific information.

Building blocks (top-down):

■ Free Format: Carrier info; From ; To ; Symbol indicating the recipient needs to sign upon receipt.

■ Barcodes and HRI: AI (00)

![]() Note: This example of the GS1 Logistic Label for parcels is compliant with the CEN Harmonised Parcel Label, see [HPARCEL]. It uses the SSCC as the only parcel ID on the label.

Note: This example of the GS1 Logistic Label for parcels is compliant with the CEN Harmonised Parcel Label, see [HPARCEL]. It uses the SSCC as the only parcel ID on the label.

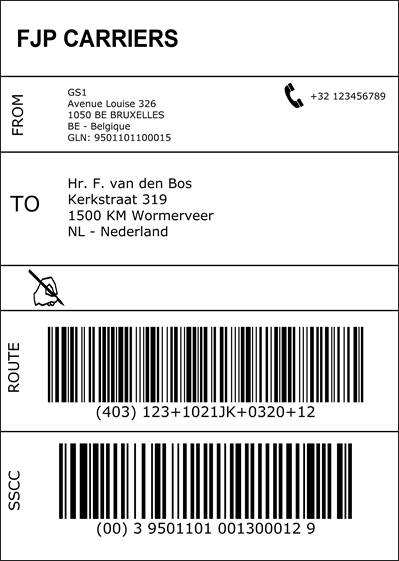

This example shows a parcel label that contains name and address information, an SSCC and a carrier-specific routing code. The routing code is carrier-specific and intended to aid migration to a fully generic parcel label (see section5.4). The other information is generic and suitable for any parcel carrier.

Building blocks (top-down):

■ Free Format: Carrier info ; From ; To ; Symbol indicating the recipient needs to sign upon receipt.

■ Text with Data Titles: SSCC; ROUTE

■ Barcodes and HRI: AI (403); AI (00)

![]() Note: This example of the GS1 Logistic Label for parcels is compliant with the CEN Harmonised Parcel Label, see [HPARCEL]. It uses the SSCC as the shipper-assigned parcel ID on the label, and in addition an optional carrier specific or UPU parcel ID, represented using AI (403).

Note: This example of the GS1 Logistic Label for parcels is compliant with the CEN Harmonised Parcel Label, see [HPARCEL]. It uses the SSCC as the shipper-assigned parcel ID on the label, and in addition an optional carrier specific or UPU parcel ID, represented using AI (403).

This example shows a parcel label that contains name and address information, an SSCC and a carrier-specific routing code. The routing code is carrier-specific and intended to aid migration to a fully generic parcel label (see section5.4). The other information is generic and suitable for any parcel carrier.

![]()

Building blocks (top-down):

■ Free Format: Carrier info; From; To;

■ Text with Data Titles and GS1 DataMatrix: SSCC; ROUTE, SHIP TO POST

■ GS1-128 and HRI: AI (00)

![]() Note: This example shows a GS1 DataMatrix, a GS1 QR Code would also be acceptable.

Note: This example shows a GS1 DataMatrix, a GS1 QR Code would also be acceptable.

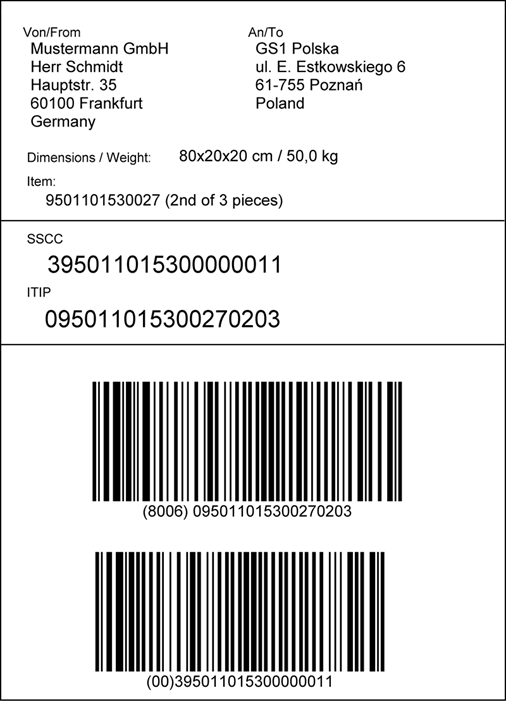

This example shows a label that contains the identifier of a piece of a trade item, using AI (8006). It corresponds with item B in the scenario (see section 4.3) in which each piece of a trade item is a separate logistic unit.

Building blocks (top-down):

■ Free Format: From; To, Dimensions / Weight, Item

■ Text with Data Titles: SSCC; ITIP;

■ Barcodes and HRI: AI (8006); AI (00)

11 References

■ [CHECK] https://www.gs1.org/check-digit-calculator

■ [GENSPECS] GS1 General Specifications - version 19, GS1 2019

■ [TLKEYS] GS1 Identification Keys in Transport & Logistics, GS1 2013

https://www.gs1.org/docs/tl/T_L_Keys_Implementation_Guideline.pdf

■ [1DVER] GS1 Barcode Verification Process (implementation guide), GS1 2015

■ [HPARCEL] Postal services - Interfaces for cross border parcels, CEN 2017

■ [ELL] GS1 in Europe Logistic Label version 14, GS1 in Europe 2007

■ [STILL] Standard International Logistic Label (STILL), GS1 2007

![]() Important: The information contained in the STILL guideline has been incorporated in the new GS1 Logistic Label Guideline. The STILL guideline will no longer be updated.

Important: The information contained in the STILL guideline has been incorporated in the new GS1 Logistic Label Guideline. The STILL guideline will no longer be updated.

A Appendix A - GS1 Logistic Label verification

This section provides a brief summary of the GS1 Logistic Label verification procedures as applied by GS1 Member Organisations in order to assess the quality of logistic labels.

![]() Note: Verification of the GS1-128 symbol is not described in this section. Please refer to the Barcode Verification Process - Implementation Guide [1DVER] for guidance on this topic.

Note: Verification of the GS1-128 symbol is not described in this section. Please refer to the Barcode Verification Process - Implementation Guide [1DVER] for guidance on this topic.

Logistic label verification aims at checking the label's compatibility with the GS1 standards and guidelines. Verification helps to ensure that GS1 Logistic Label implementations comply with the GS1 System, and result in logistic labels that can be used by all supply chain partners.

Verification should be an integral part of quality control processes. It should be performed during initial implementation and repeated at regular intervals once operational.

Verification can be performed by GS1 Member Organisations or by companies authorised by GS1 to issue such verification. In case of a problem, standard verification reports should be used to communicate the source of the problem.

A.2 Common verification approach

To ensure a common logistic label verification approach a standard verification procedure is needed. This will guarantee similar results regardless of where the symbols are tested. This section aims at highlighting critical issues relating to verification.

The visual assessment includes:

■ the dimension of the label

■ the correct placement of segments and building blocks

■ correct languages of data titles applied

■ correct data titles in the middle part for encoded information

■ Are there any lines through the barcodes or speckles?

■ Is the barcode at least 31.75 mm / 1.250" high?

■ Is there sufficient space on either side of the barcode?

Data content verification includes:

■ GS1 Company Prefix (or prefixes applied)

■ GS1 identification keys applied (e.g. GTIN, SSCC)

■ check digits of all GS1 identification keys applied (e.g. GTIN, SSCC)

■ Applied GS1 Application Identifiers and their structure

Verification of technical parameters includes all the checks for GS1-128 symbols as defined in the [1DVER] guide, and additionally:

■ correct combinations of data elements, mandatory association of data elements (e.g. AI (02) and AI (37))

■ correct structure of data elements

■ correct check digits of GS1 identification keys (e.g. GTIN, SSCC) presented in the barcode symbol.

![]() Note: In case barcode symbols other than GS1-128 are present on the label, in addition to GS1-128 symbols holding the SSCC and other attributes, the verification report will only address the correctness of the GS1-128 symbols and data contained therein. The verification report SHOULD include a warning that non-allowed GS1 symbols or non-GS1 symbols have been detected.

Note: In case barcode symbols other than GS1-128 are present on the label, in addition to GS1-128 symbols holding the SSCC and other attributes, the verification report will only address the correctness of the GS1-128 symbols and data contained therein. The verification report SHOULD include a warning that non-allowed GS1 symbols or non-GS1 symbols have been detected.

Verification reports should include:

■ the list of parameters that were verified

■ information on whether a given parameter complies with GS1 requirements

■ in case of a negative assessment - information on correct data and recommendations on how to avoid mistakes

■ A copy of the verified label should be attached to the report.

Contributors & Change Log

| First Name | Last Name | Company |

|---|---|---|

| Alejandra | Montes de Oca | GS1 Mexico |

| Amber | Walls | GS1 US |

| Bo | Bäckstr\F6m | Axfood Sverige AB |

| Bonnie | Ryan | GS1 Australia |

| Christine | Chang | 3M Healthcare |

| Cyndi | Poetker | Abbott |

| Dan | Mullen | GS1 Global Office |

| Daniel | Mueller-Sauter | GS1 Switzerland |

| David | Buckley | GS1 Global Office |

| Denis | O'Brien | GS1 Ireland |

| Don | Roskowiak | Target Corporation |

| Ed | Jesus | Chep |

| Eugen | Sehorz | GS1 Austria |

| Gary | Hartley | GS1 New Zealand |

| George | Sarantavgas | GS1 Association Greece |

| George | Wright IV | Product Identification & Processing Systems |

| Gerald | Gruber | GS1 Austria |

| Giada | Necci | GS1 Italy |

| Ginger | Green | Wal-Mart Stores, Inc. |

| Glyn | Fogell | Shoprite Checkers |

| Heide | Buhl | GS1 Germany |

| Heinz | Graf | GS1 Switzerland |

| Hirokazu | Nagai | Japan Pallet Rental Corporation |

| Holger | Strietholt | Schweizerische Bundesbahnen SBB |

| Ildik\F3 | Lieber | GS1 Hungary |

| Ilka | Machemer | GS1 Germany |

| Jaco | Voorspuij | GS1 Global Office |

| Jane | Wulff | GS1 Denmark |

| Jean-Christophe | Gilbert | GS1 France |

| Jeanne | Duckett | Avery Dennison RFID |

| Jeffrey | Cree | Ahold (USA) |

| John | Terwilliger | Abbott |

| John | Pearce | Axicon Auto ID Ltd |

| John | Ryu | GS1 Global Office |

| Jonas | Buskenfried | GS1 Sweden |

| Kai | Hachmann | Edeka Zentrale AG & Co. KG |

| Karen | Arkesteyn | GS1 Belgium & Luxembourg |

| Karolin | Harsanji | GS1 Sweden |

| Kevin | Dean | GS1 Canada |

| Kimmo | Keravuori | GS1 Finland |

| Linda | Vezzani | GS1 Italy |

| Luiz | Costa | GS1 Brasil |

| Madalena | Centeno | GS1 Portugal |

| Margarita | Bykova | GS1 Russia |

| Margarita | Bykova | GS1 Russia |

| Marianna | Revallova | GS1 Slovakia |